Automatic calibration device for dynamic error of movable on-line oil gas monitoring system

A monitoring system and automatic calibration technology, applied in the field of power supply and transformation, can solve the problems of inability to evaluate equipment status, low test stability and accuracy, etc., and achieve mobility, improve stability and accuracy, and move flexibly and conveniently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

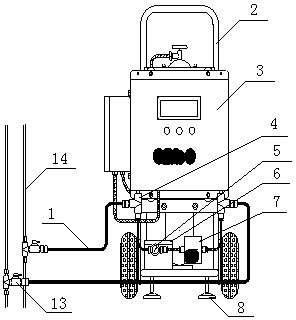

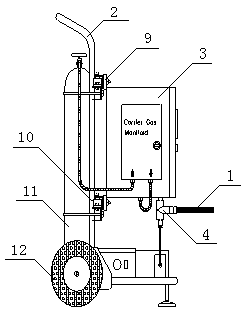

[0015] Such as figure 1 - figure 2 As shown, the error dynamic automatic calibration device of a movable oil-gas online monitoring system of the present invention includes oil delivery pipe 1, high-strength carbon steel frame 2, Calisto 9 type high-precision oil-in-gas online monitoring system 3, stainless steel tee 4, Flow indicator 5, power control box 6, pipeline cleaning circulation pump 7, universal support frame 8, disc broadband shock absorber 9, load low frequency composite shock absorber 10, aluminum alloy carrier gas cylinder 11, vibration-absorbing pneumatic tire 12. Precision quick-change joint 13, transformer oil pipe 14, the high-strength carbon steel frame 2 is an L-shaped frame, and vibration-absorbing pneumatic tires 12 are arranged on both sides of the rear end of the high-strength carbon steel frame 2 horizontal frame; The high-strength carbon steel frame 2 is provided with a power supply control box 6 and a pipeline cleaning circulation pump 7 on the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com