Independent pilot-operated type flow control valve

A technology of flow control valve and pilot-operated relief valve, applied in valve details, safety valve, balance valve, etc., can solve the problems of limited life of membrane sheet under pressure, short life of control valve, frequent replacement, etc. Quick and reliable coordination response, reliable non-return function, good coordination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

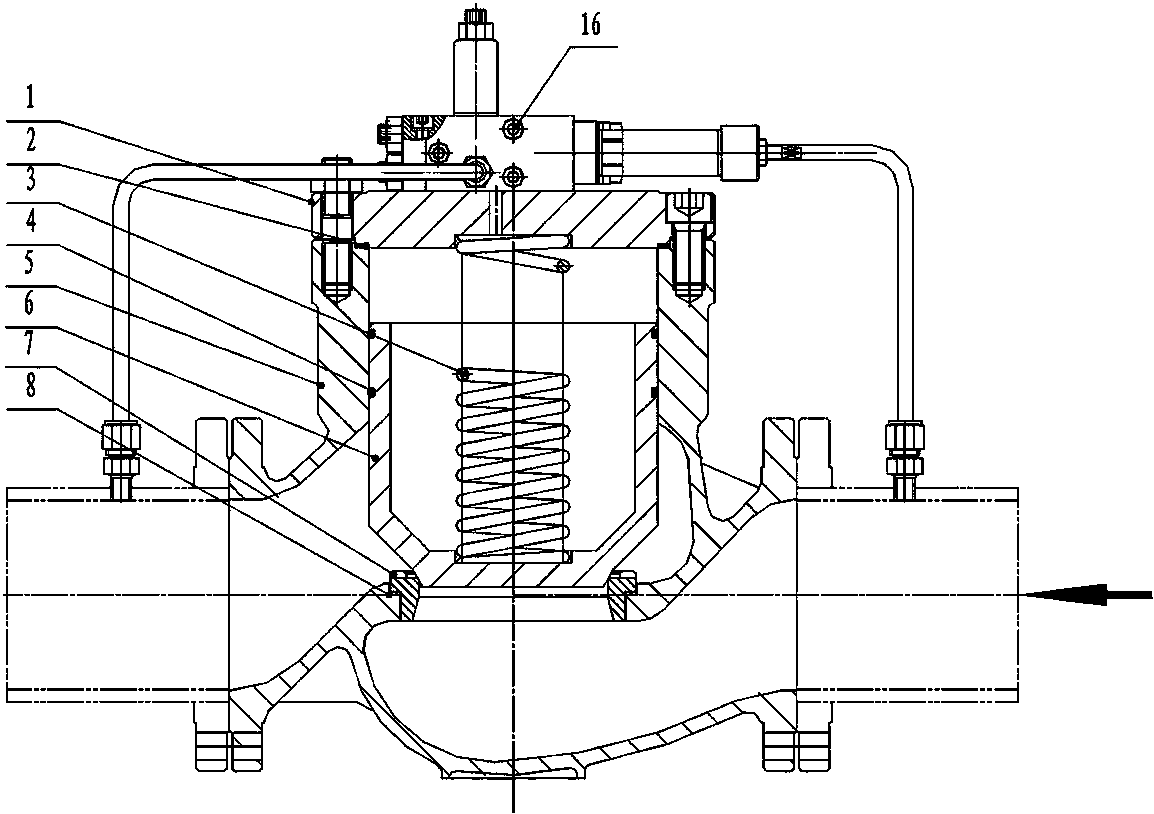

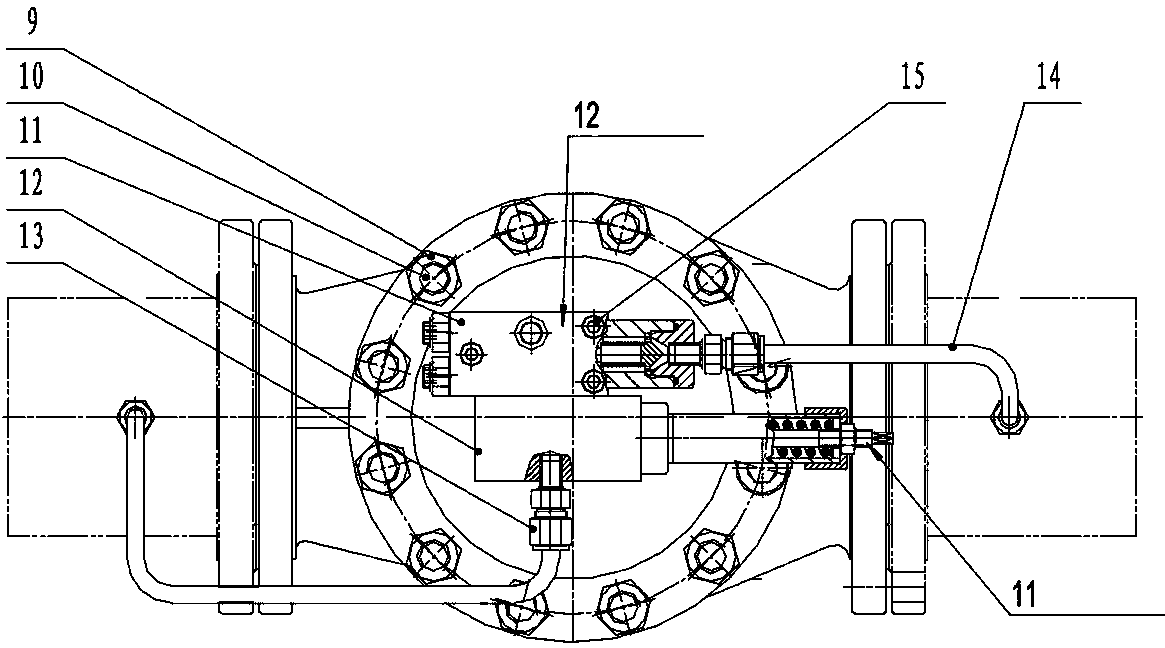

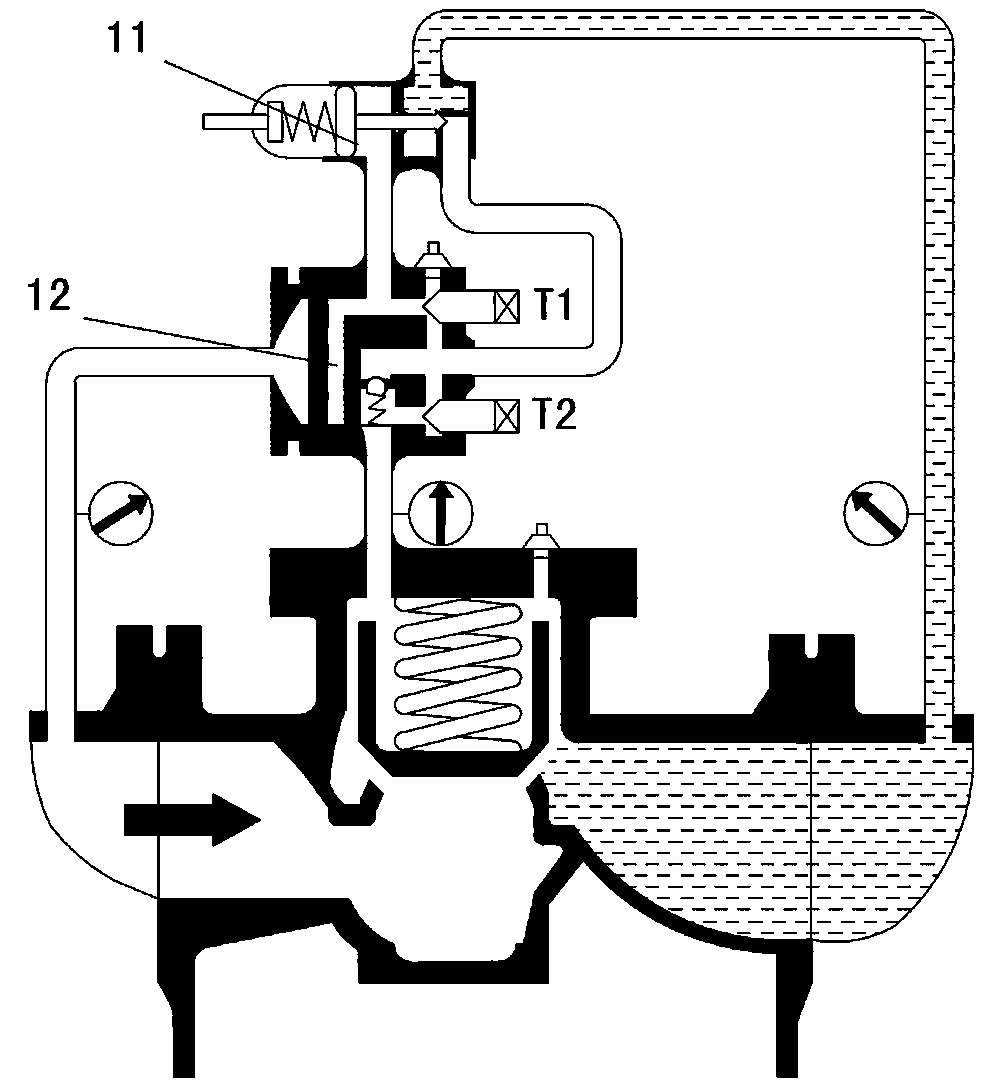

[0022] See attached Figure 1-3 As shown, the purpose of a self-operated pilot-operated flow control valve is achieved through the following technical solutions: The self-operated pilot-operated flow control valve is generally composed of a main valve, a pilot-operated overflow valve 11, and a control manifold 12. The part above the main valve is the actuator, which is composed of a hydraulic control element manifold and a pilot relief valve. Fix it on the integrated block of the hydraulic control element with the hexagon socket head cap screw 16. The integrated block of the hydraulic control element is connected to the inlet front section pipeline of the valve by the medium collection inlet pipe fitting group 14, and the pilot relief valve is connected to the outlet rear section pipeline of the valve by the outlet pipe fitting group 13.

[0023] attached Figure 1-3 As shown in , the main valve includes a valve body 5, a sealing valve seat 7 set in the middle of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com