Chrome-free metal deactivator

A passivating agent, chromium metal technology, applied in the direction of metal material coating process, etc., can solve the problems of non-explosive, non-flammable, etc., and achieve the effect of strong corrosion resistance and good film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

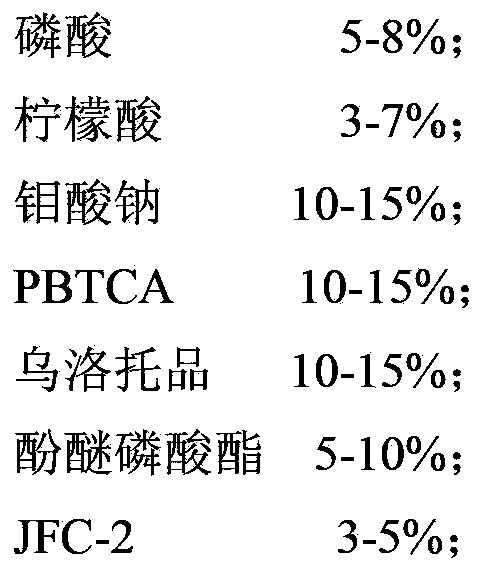

[0034] A chromium-free metal passivator, comprising the following components, and the weight percentage of each component is:

[0035]

[0036] Add water to 100%.

[0037] Preparation method: Mix all ingredients evenly and dissolve together.

Embodiment 2

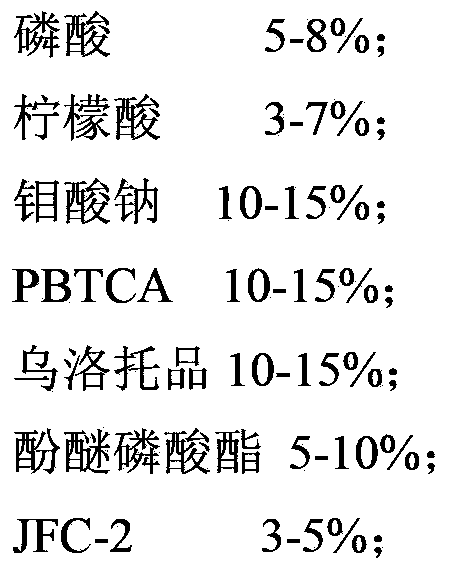

[0039] A chromium-free metal passivator, comprising the following components and the weight percentage of each component is:

[0040]

[0041] The balance is water.

[0042] The preparation method is the same as in Example 1.

Embodiment 3

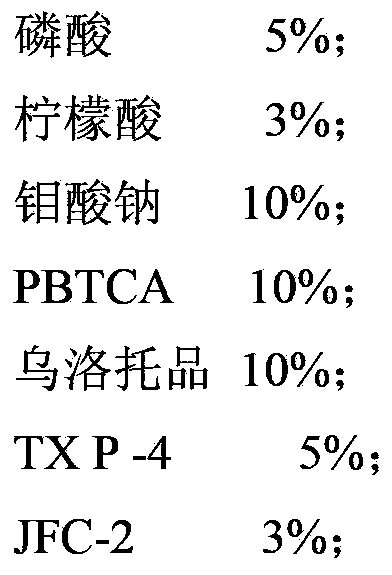

[0044] A chromium-free metal passivator, comprising the following components and the weight percentage of each component is:

[0045]

[0046] The balance is water.

[0047] The preparation method is the same as in Example 1.

[0048] Salt spray test judgment standard: national standard GB6461, GB12335

[0049] Implementation experimental status rating factor Example 1 discoloration and light loss Grade C Example 2 no change Grade A Example 3 slight discoloration Class B

[0050] How to use: The preparation ratio is 1:5--1:10, that is, 1 part of chromium-free passivator is diluted with 5 parts to 10 parts of deionized water. Do not use tap water, let alone well water

[0051] Note: The surface temperature of galvanized sheet and other galvanized materials should be controlled below 45°C. When the temperature exceeds 50°C, the passivator may be decomposed and the corrosion resistance will be damaged. The passivation layer has c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com