Aluminum-gallium co-doping zinc oxide nano-powder and preparation method for high intensity high conductivity sputtering coating target material thereof

A technology of zinc oxide nanometer and zinc oxide powder, applied in the fields of powder metallurgy and ceramics, can solve the problems of expensive equipment, inability to prepare large-size target materials, and poor performance of AZO film, and achieve the effect of improving density and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

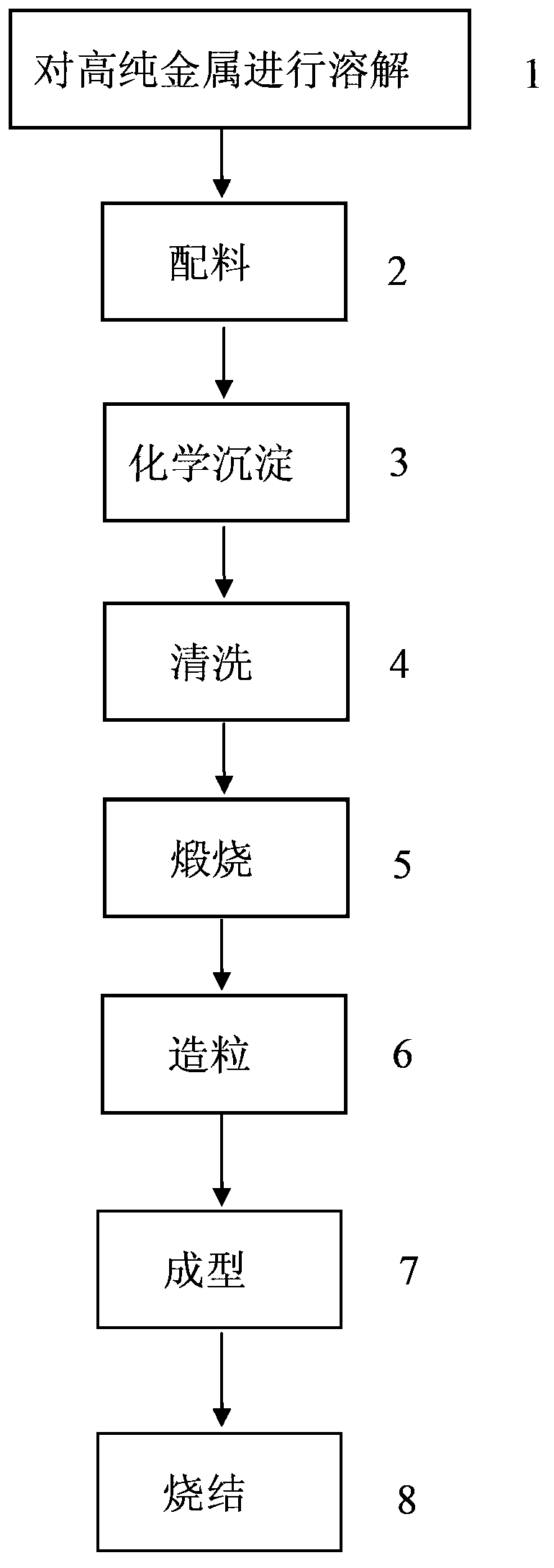

[0066] The invention discloses a method for preparing aluminum-gallium co-doped zinc oxide nanopowder and its high-density and high-conductivity sputtering coating target, comprising the following steps:

[0067] Step 1 metal dissolution: dissolving high-purity metals: using nitric acid to dissolve high-purity metal aluminum, high-purity metal zinc, and high-purity metal gallium to form transparent aluminum nitrate, zinc nitrate and gallium nitrate solutions.

[0068] Step 2 for batching: divide the above three transparent solutions into containers according to the predetermined ratio, that is, according to the atomic ratio of 97% Zn, 3% (Al+Ga) (the optimal atomic ratio is Zn:Al:Ga=97:2.7: 0.3) Divide into respective containers for later use.

[0069] Step 3 chemical precipitation: use the homogeneous co-precipitation method to mix the above three transparent solutions in a 5000mL three-necked beaker according to the molar ratio of zinc, aluminum and gallium as Zn:Al:Ga=97:2....

Embodiment 2

[0076] The invention discloses a method for preparing aluminum-gallium co-doped zinc oxide nano-powder and its high-density and high-conductivity sputtering coating target, comprising the following steps:

[0077] Step 1 metal dissolution: dissolving high-purity metals: using nitric acid to dissolve high-purity metal aluminum, high-purity metal zinc, and high-purity metal gallium to form transparent aluminum nitrate, zinc nitrate and gallium nitrate solutions.

[0078] Step 2: batching: batching: the above three transparent solutions are divided into containers according to a predetermined ratio, that is, according to the atomic ratio of 97% Zn, 3% (Al+Ga) (the preferred atomic ratio is Zn:Al:Ga=97 :2.7:0.3) Pack into respective containers for later use.

[0079] Step 3 Chemical Precipitation: Use the homogeneous co-precipitation method to mix the above three transparent solutions in a 5000mL three-necked beaker according to the molar ratio of zinc, aluminum, and gallium in th...

Embodiment 3

[0086] The invention discloses a method for preparing aluminum-gallium co-doped zinc oxide nanopowder and its high-density and high-conductivity sputtering coating target, comprising the following steps:

[0087] Step 1 metal dissolution: dissolving high-purity metals: using nitric acid to dissolve high-purity metal aluminum, high-purity metal zinc, and high-purity metal gallium to form transparent aluminum nitrate, zinc nitrate and gallium nitrate solutions.

[0088] Step 2: batching: batching: the above three transparent solutions are divided into containers according to the predetermined ratio, that is, according to the atomic ratio of 97% Zn, 3% (Al+Ga) (the optimal atomic ratio is Zn:Al:Ga=97 :2.7:0.3) Pack into respective containers for later use.

[0089] Step 3 chemical precipitation: use the homogeneous co-precipitation method to mix the above three transparent solutions in a 5000mL three-necked beaker according to the molar ratio of zinc, aluminum and gallium in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com