Method for preparing graphene film at low temperature

A graphene film and low temperature technology, applied in the field of low temperature preparation of graphene films, can solve problems such as unfavorable large-scale preparation of graphene, and achieve the effects of avoiding processing steps and reducing preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: concrete steps are:

[0019] 1) Pretreatment: Ultrasonic cleaning of copper foil (1cm*1cm) with a thickness of 25 microns and a purity of 99.8wt% in acetone, isopropanol, and deionized water for 20 minutes in sequence, and dried with nitrogen.

[0020] 2) Preparation of DLC film: A layer of DLC film was prepared on the copper substrate obtained in step 1) using radio frequency plasma enhanced chemical vapor deposition technology. The reaction gas was a mixture of methane and hydrogen with a purity of 99.999% (methane 1%), and the reaction chamber The background vacuum is Pa, the gas pressure during deposition is 266Pa, the radio frequency power is 200W, and the deposition time is 5 minutes.

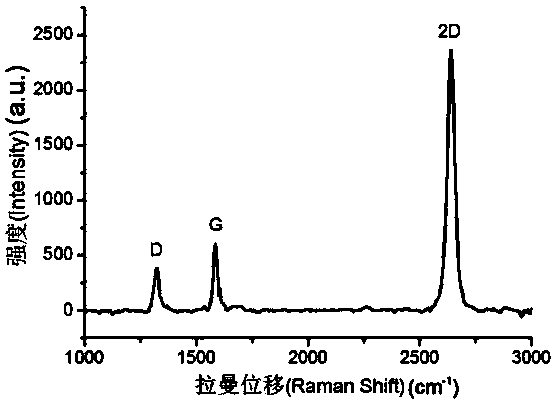

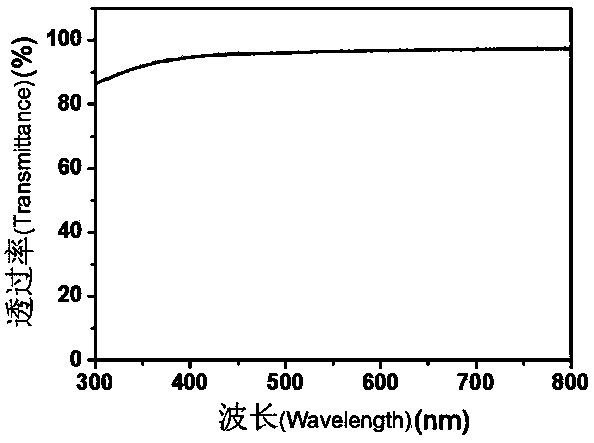

[0021] 3) Graphene growth: Place the copper substrate covered with DLC film obtained in step 2) in a CVD reaction chamber, evacuate until the pressure in the reaction chamber drops below 0.1Pa, and introduce a hydrogen / argon mixed gas (hydrogen 10% ) to normal pres...

Embodiment 2

[0024] 1) Pre-treatment: The nickel foil (1cm*1cm) with a thickness of 505 microns and a purity of 99.8wt% was ultrasonically cleaned in acetone, isopropanol, and deionized water for 20 minutes, and dried with nitrogen.

[0025] 2) Preparation of patterned DLC film: A layer of DLC film was prepared on the nickel substrate obtained in step 1) by radio frequency plasma enhanced chemical vapor deposition technology, and the reaction gas was a mixture of methane and hydrogen with a purity of 99.999% (methane 1%), The background vacuum of the reaction chamber is Pa, the gas pressure during deposition is 188Pa, the radio frequency power is 200W, and the deposition time is 30 minutes.

[0026] 3) Patterned graphene growth: Place the nickel substrate covered with DLC film obtained in step 2) in the CVD reaction chamber, evacuate until the pressure in the reaction chamber drops below 0.1Pa, and then inject argon gas to normal pressure, repeat the process Step 2-3 times, control the m...

Embodiment 3

[0028] 1) Pre-treatment: ultrasonically clean the copper-nickel alloy foil (1cm*1cm) in acetone, isopropanol, and deionized water for 20 minutes in sequence, and blow dry with nitrogen.

[0029] 2) Preparation of patterned DLC film: A layer of DLC film was prepared on the copper-nickel-nickel alloy substrate obtained in step 1) by radio frequency plasma enhanced chemical vapor deposition technology, and the reaction gas was a mixture of methane and hydrogen with a purity of 99.999% (methane 1 %), the background vacuum of the reaction chamber is Pa, the gas pressure during deposition is 188Pa, the radio frequency power is 200W, and the deposition time is 10 minutes.

[0030] 3) Patterned graphene growth: place the copper-nickel alloy substrate covered with DLC film obtained in step 2) in a CVD reaction chamber, evacuate until the pressure in the reaction chamber drops below 0.1Pa, and then pass in argon gas to normal pressure, Repeat this step 2-3 times, control the mixed gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com