Nitrogenous NaY type molecular sieve composite adsorption material, preparation method and application

A composite adsorption material and molecular sieve technology, which is applied in the field of CO2 treatment in air pollution control, to achieve the effects of high adsorption efficiency, low processing cost, and simple and easy adsorption operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

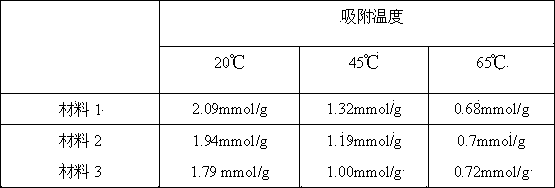

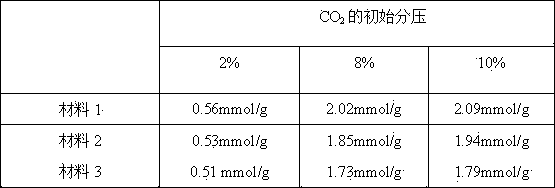

Examples

Embodiment 1

[0028] (1) Put 200ml of hydrochloric acid with a concentration of 1mol / L in a 500ml beaker, then add 60mg of NaY molecular sieves, and ultrasonically disperse uniformly at room temperature (ultrasonic time is 2d) to obtain a suspension of NaY molecular sieves.

[0029] (2) Add 1.6 g of ammonium persulfate to another 200 ml of hydrochloric acid with a concentration of 1 mol / L, stir until dissolved, and obtain ammonium persulfate acid solution, which is set aside.

[0030] (3) Take 1.6g of aniline and add it to the suspension of NaY molecular sieve, ultrasonically disperse evenly at 2°C (ultrasonic time is 6h), add all the ammonium persulfate solution prepared in step (2) dropwise, in 2 Under the condition of ℃, aniline is polymerized on NaY type molecular sieve, the reaction time is 24h, and solid particles are obtained.

[0031] (4) The solid particles were washed with distilled water, ethanol and acetone in turn until neutral, and dried at 75°C to obtain Material 1, which was...

Embodiment 2

[0033] (1) Put 200ml of hydrochloric acid with a concentration of 1mol / L in a 500ml beaker, then add 60mg of NaY molecular sieve, and disperse uniformly by ultrasonic at room temperature (ultrasonic time is 18h), to obtain a suspension solution of NaY molecular sieve.

[0034] (2) Add 2 g of ammonium persulfate to another 200 ml of hydrochloric acid with a concentration of 1 mol / L, stir until dissolved, and obtain an ammonium persulfate acid solution for later use.

[0035] (3) Take 2g of aniline and add it to the suspension solution of NaY molecular sieve, and disperse it uniformly under the condition of 3°C (ultrasonic time is 4h), add all the ammonium persulfate solution prepared in step (2) drop by drop, at 0°C Under the conditions, aniline is polymerized on NaY molecular sieves, and the reaction time is 24 hours to obtain solid particles.

[0036] (4) Wash the solid particles with distilled water, ethanol and acetone in turn until neutral, and dry at 65°C to obtain materi...

Embodiment 3

[0038] (1) Put 200ml of hydrochloric acid with a concentration of 1mol / L in a 500ml beaker, then add 60mg of NaY molecular sieve, and disperse uniformly by ultrasonic at room temperature (ultrasonic time is 2d) to obtain a suspension of NaY molecular sieve.

[0039] (2) Add 2.4 g of ammonium persulfate to another 200 ml of hydrochloric acid with a concentration of 1 mol / L, stir until dissolved, and obtain ammonium persulfate acid solution, which is set aside.

[0040] (3) Take 2.4g of aniline and add it to the suspension of NaY molecular sieve, ultrasonically disperse evenly at 4°C (ultrasonic time is 6h), add all the ammonium persulfate solution prepared in step (2) drop by drop, in Aniline was polymerized on NaY molecular sieve at 5°C for 30 hours to obtain solid particles.

[0041] (4) The solid particles were washed with distilled water, ethanol and acetone in turn until neutral, and dried at 80°C to obtain material 3, which was stored in a desiccator for future use.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com