Thermoplastic resin composition, and molded product thereof

A technology of thermoplastic resin and composition, applied in the direction of coating, etc., can solve the problems of insufficient effect of viscosity modifier and limitation of thermoplastic resin, and achieve the effects of excellent retention stability, high transparency and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19

[0195] [Examples 1-19, Comparative Examples 1-24]

[0196] After dry-blending each component in the ratios listed in Tables 2 to 4, it is supplied from the main feeder of the extruder, and the TEX30 twin-screw extruder manufactured by Nippon Steel Works is set to the The set temperature of the barrel was set at a screw speed of 200rpm for melting and kneading, and the strips discharged from the die were immediately cooled by a water bath and pelletized by a strand pelletizer. The granules obtained in Examples 7, 8, 12, 16, 17 and Comparative Examples 6-9, 16, 17, 21, and 22 were vacuum-dried at 80°C for 12 hours, and the other granules were dried with hot air at 120°C for 5 hours. , perform the following evaluations.

Embodiment 20~25

[0197] [Examples 20-25, Comparative Examples 25-31]

[0198] Dry blend the thermoplastic resin component and the poly(phenylene ether ketone) of Reference Example 1 or 2 at the ratios listed in Table 5, then supply it from the main feeder of the extruder, and feed the filler from the side of the extruder Machine supply, with the TEX30 type twin-screw extruder made by Japan Steel Works, set to the barrel setting temperature recorded in the table, melt and knead with the screw speed of 200rpm, and the strips discharged from the die head immediately Cool in a water bath and granulate through a strand pelletizer. The pellets obtained in Examples 22 and 23 and Comparative Examples 28 and 29 were vacuum-dried at 80°C for 12 hours, and the other pellets were dried with hot air at 120°C for 5 hours, and then evaluated as follows.

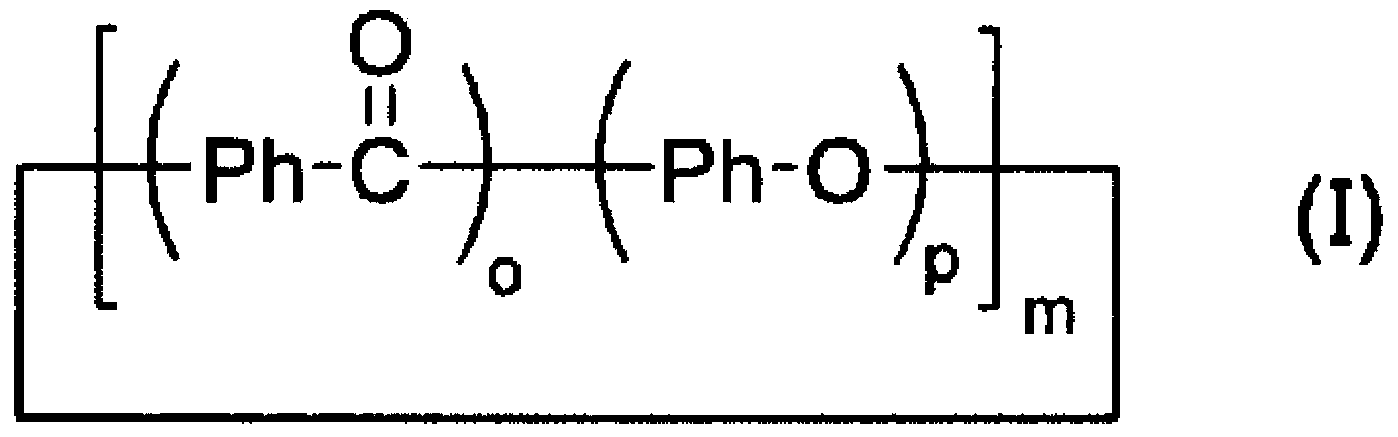

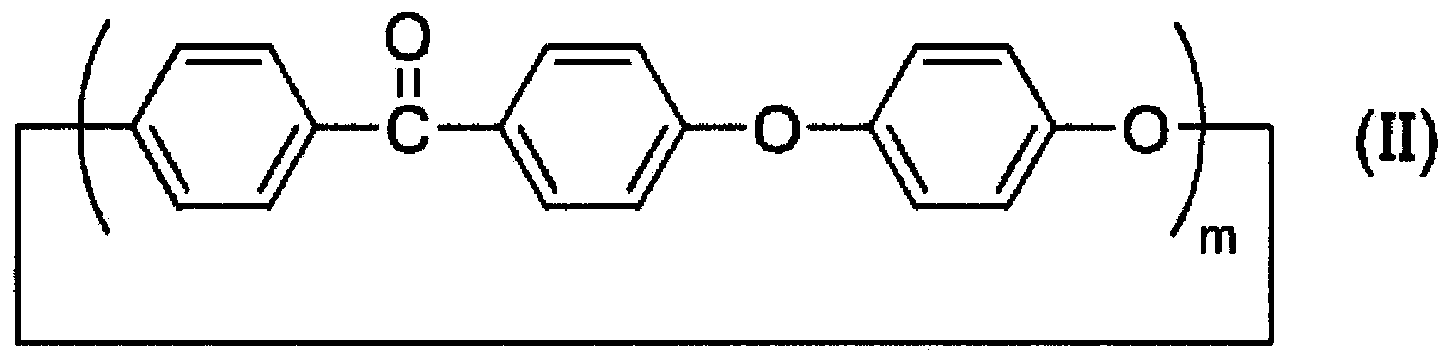

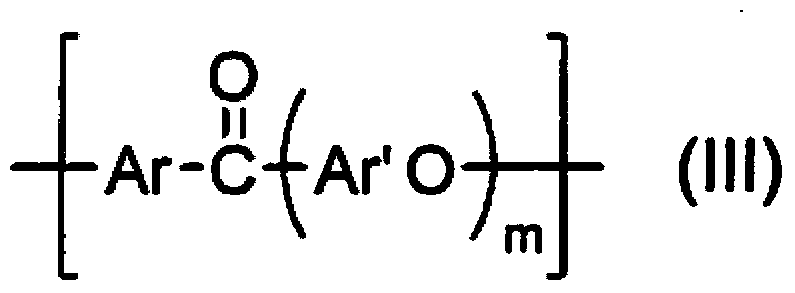

[0199] (B) poly(phenylene ether ketone) used in the present example or comparative example is as follows.

[0200] B-1: Reference example 1

[0201] B-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com