Polyamide and polyamide composition

A technology of polyamide and diamine, applied in the field of polyamide and polyamide composition, can solve the problem of difficulty in obtaining molded products, and achieve the effects of excellent heat-resistant reflow solderability and excellent fogging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

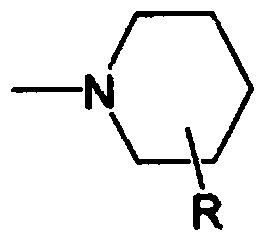

Method used

Image

Examples

Embodiment 1

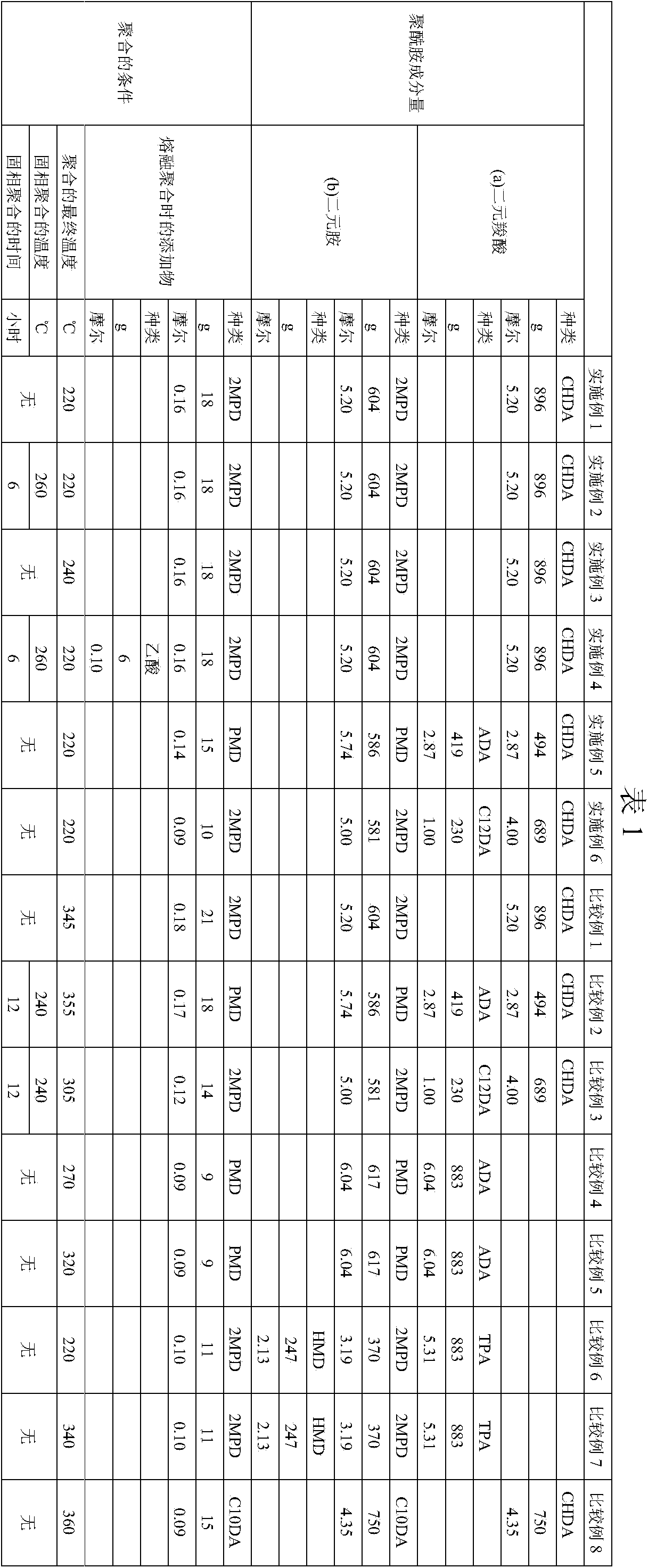

[0417] The polyamide polymerization reaction is carried out by the "prepolymer-solid-phase polymerization method".

[0418] (a) 896 g (5.20 mol) of CHDA and (b) 604 g (5.20 mol) of 2MPD were dissolved in 1500 g of distilled water to prepare a 50% by mass aqueous solution containing equimolar raw material monomers.

[0419] The resulting aqueous solution and 2MPD 18g (0.16 mol) as an additive during polymerization were put into an autoclave with an internal volume of 5.4L (Nitto High Pressure), and kept warm until the liquid temperature (internal temperature) reached 50°C, and then the inside of the autoclave was Replace with nitrogen.

[0420] Continue heating from the liquid temperature of about 50°C until the pressure in the tank of the autoclave reaches about 2.5kg / cm2 in terms of gauge pressure (hereinafter, the pressure in the tank is all expressed in gauge pressure) 2 .

[0421] In order to keep the pressure in the tank at about 2.5kg / cm 2 , remove water to the outsid...

Embodiment 2

[0427] Using the polyamide obtained in [Example 1] above, "solid phase polymerization" was further implemented.

[0428] 10 kg of polyamide pellets obtained by the prepolymer-solid-state polymerization method were charged into a conical belt vacuum dryer (manufactured by Okawara Seisakusho Co., Ltd., trade name リボコーン RM-10V) and fully replaced with nitrogen.

[0429] Heating was performed at 260° C. for 6 hours while stirring while blowing nitrogen gas at 1 L / min. Then, the temperature was lowered while flowing nitrogen gas, and when it reached about 50° C., the pellets were taken out from the apparatus as they were to obtain a polyamide.

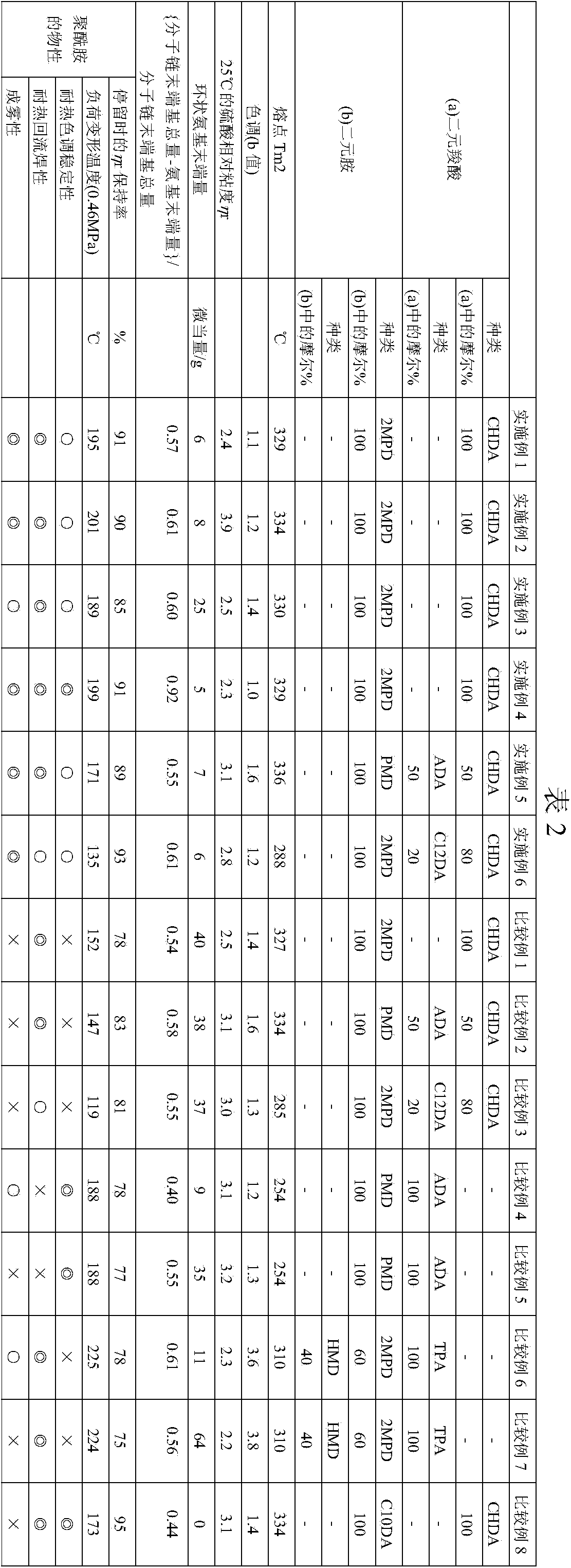

[0430] The measurements of (1) to (10) above were performed on the obtained polyamide.

[0431] The measurement results are shown in Table 2.

Embodiment 3~6

[0433] As (a) dicarboxylic acid, (b) diamine, and additives during polymerization, the compounds and amounts described in Table 1 below were used. In Example 4, acetic acid was used as an end-capping agent.

[0434] In addition, the final temperature of polymerization was set to the temperature described in Table 1.

[0435] Regarding other conditions, the polyamide was polymerized by the prepolymer / solid phase polymerization method described in Example 1.

[0436] In addition, as the temperature and time of solid phase polymerization, the temperature and time described in Table 1 below were used. Regarding other conditions, solid phase polymerization was performed in the same manner as in Example 2 above.

[0437] The measurements of (1) to (10) above were performed on the obtained polyamide.

[0438] The measurement results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com