Bosch etching method

A technology of etching holes and etching gas, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that the stability of the etching process needs to be improved, and achieve fast etching directionality and high etching morphology. Good, less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B

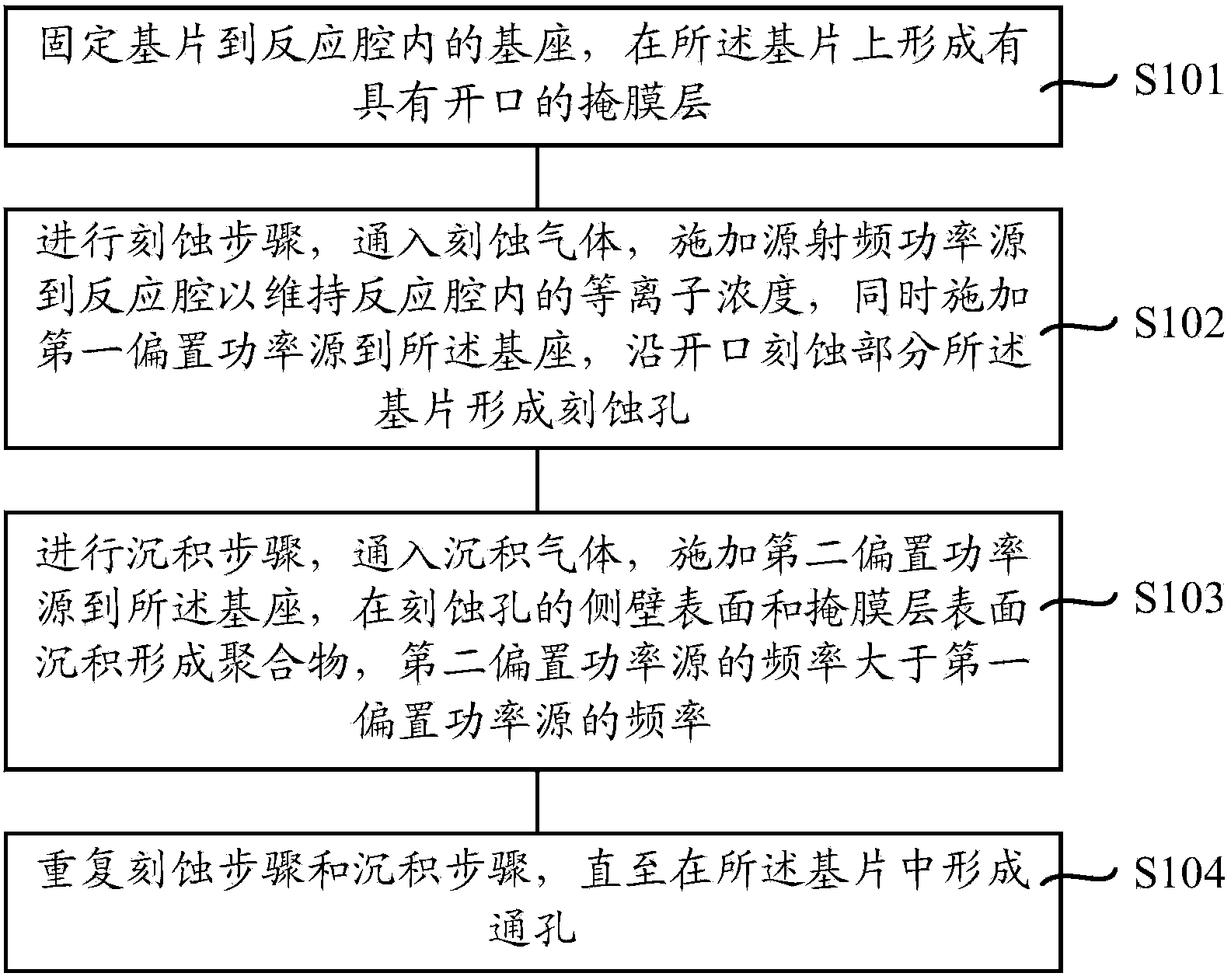

[0028] figure 1 It is a schematic flow diagram of the Bosch etching method of the embodiment of the present invention, including:

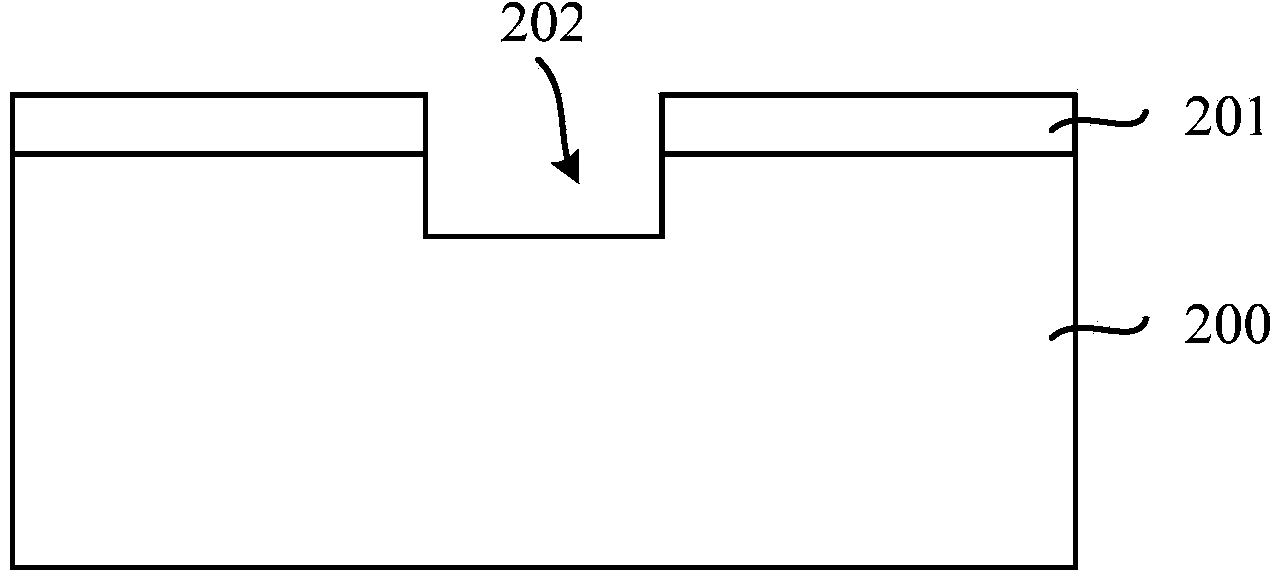

[0029] Step S101, fixing the substrate to the base in the reaction chamber, and forming a mask layer with openings on the substrate;

[0030] Step S102, performing an etching step, feeding an etching gas, applying a source radio frequency power source to the reaction chamber to maintain the plasma concentration in the reaction chamber, and simultaneously applying a first bias power source to the base, and etching a part along the opening The substrate forms etching holes;

[0031]Step S103, performing a deposition step, passing a deposition gas, applying a second bias power source to the base, depositing and forming a polymer on the sidewall surface of the etched hole and the surface of the mask layer, and the second bias power source a frequency greater than that of the first bias power source;

[0032] Step S104, repeating the etching step an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com