Method for improving underetch anomalies of patterned sapphire substrates

A technology for patterning sapphire and substrates, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of substrates not meeting customer needs, waste, pattern size changes, etc., and achieve good shape modification effect, Guaranteed clean, low bombardment energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

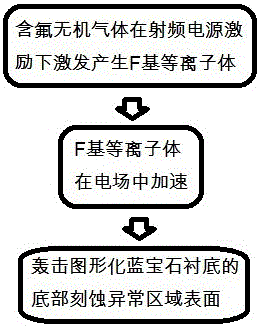

[0020] See attached figure 1 As shown, the present embodiment provides a method for improving the abnormal etching of the bottom of the patterned sapphire substrate, including the following steps:

[0021] Provide F-based plasma;

[0022] applying kinetic energy in a predetermined direction to the F-based plasma;

[0023] Make the F-based plasma bombard the bottom of the patterned sapphire substrate to etch the surface of the abnormal region from top to bottom for a predetermined time, so that at least part of the etched surface generates AlF 3 .

[0024] Specifically, by using inorganic gases containing fluorine (F), such as CHF 3 , SF 6 et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com