Manufacturing method of low-voltage and high-energy zinc oxide resistor disc

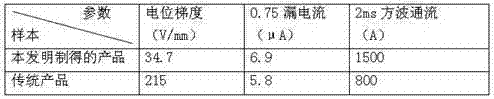

A technology of zinc oxide resistor sheet and manufacturing method, applied in resistor manufacturing, resistors, circuits, etc., can solve the problems of low residual voltage ratio, inability to meet low voltage and high current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for manufacturing a low-voltage high-energy zinc oxide resistance sheet, comprising the following process steps:

[0021] (1) Ratio of additives: In terms of molar percentage, in addition to the main material zinc oxide, additives include: 0.2% antimony trioxide, 0.8% titanium dioxide, 0.5% bismuth trioxide, 0.8% cobalt trioxide, carbonic acid Manganese 0.6%, silver nitrate 0.001%, tin dioxide 0.3%, boric acid 0.001%;

[0022] (2) Stirring and grinding of additives: add the additives with a good ratio and water equal to the weight of the additives into the ball mill for stirring and grinding, and the mixing and ball milling time is 3 hours;

[0023] (3) Mixing, dispersing, grinding and spray granulation of additives and main ingredients: Add zinc oxide, aluminum nitrate and binder PVA-1799 into the ball mill, disperse and grind for 120 minutes, and the weight ratio of aluminum nitrate to additives is 1: 300, the weight ratio of binder to zinc oxide is 1:100; t...

Embodiment 2

[0027] A method for manufacturing a low-voltage high-energy zinc oxide resistance sheet, comprising the following process steps:

[0028] (1) Ratio of additives: In terms of molar percentage, in addition to zinc oxide as the main ingredient, additives include: 0.6% antimony trioxide, 1.5% titanium dioxide, 1.3% bismuth trioxide, 2.1% cobalt trioxide, carbonic acid Manganese 1.3%, silver nitrate 0.003%, tin dioxide 0.6%, boric acid 0.006%;

[0029] (2) Stirring and grinding of additives: Add the additives with a good ratio and water equal to the weight of the additives into the ball mill for stirring and grinding. The mixing and ball milling time is 5 hours;

[0030] (3) Mixing, dispersion, grinding and spray granulation of additives and main ingredients: Add zinc oxide, aluminum nitrate and binder PVA-1799 into the ball mill, disperse and grind for 120 minutes, and the weight ratio of aluminum nitrate to additives is 1: 300, the weight ratio of binder to zinc oxide is 1:100; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com