Sliding member and production method therefor

A sliding member and sliding surface technology, used in sliding contact bearings, rotating parts that resist centrifugal force, bearing components, etc., can solve the problem of cracks at the interface, reduced wear resistance, and insufficient wear resistance. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, one embodiment of the sliding member will be described based on the drawings.

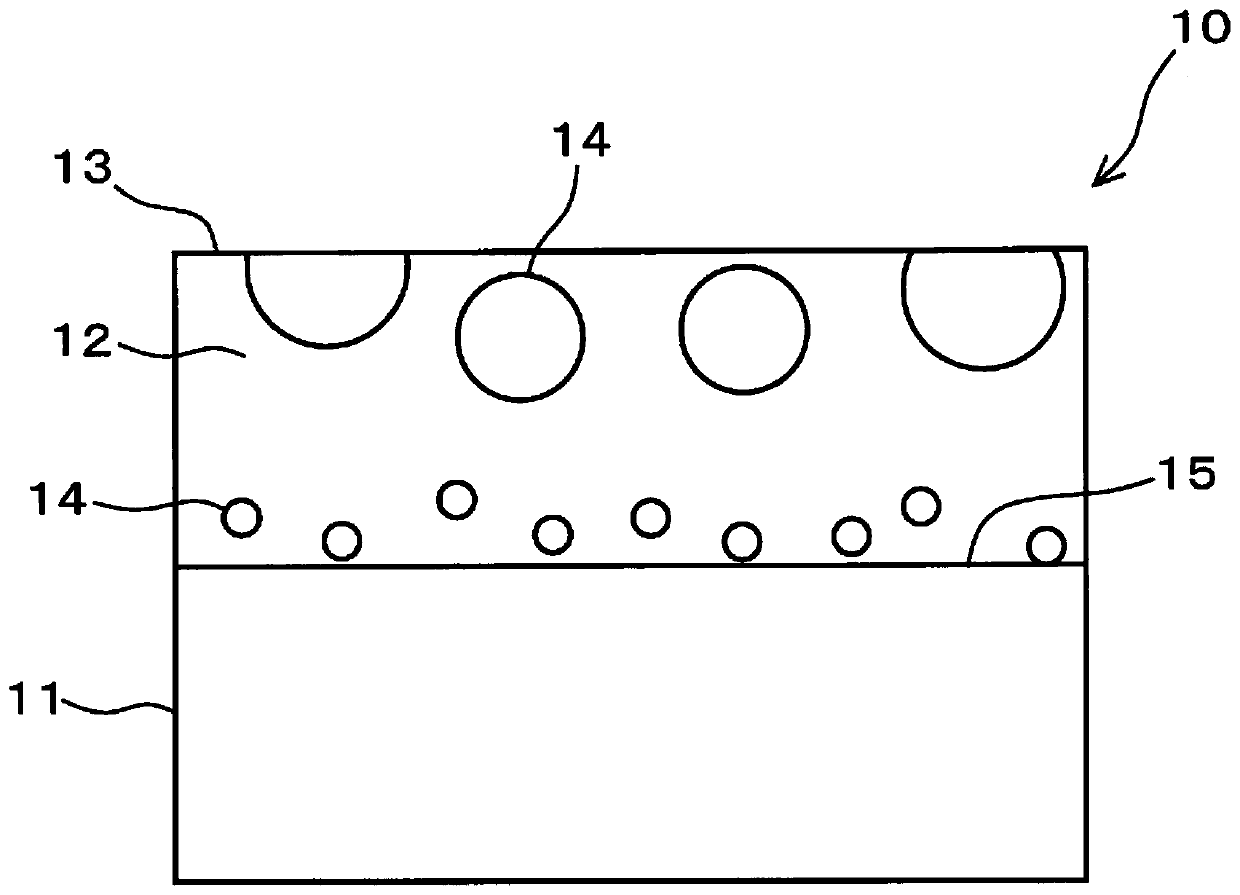

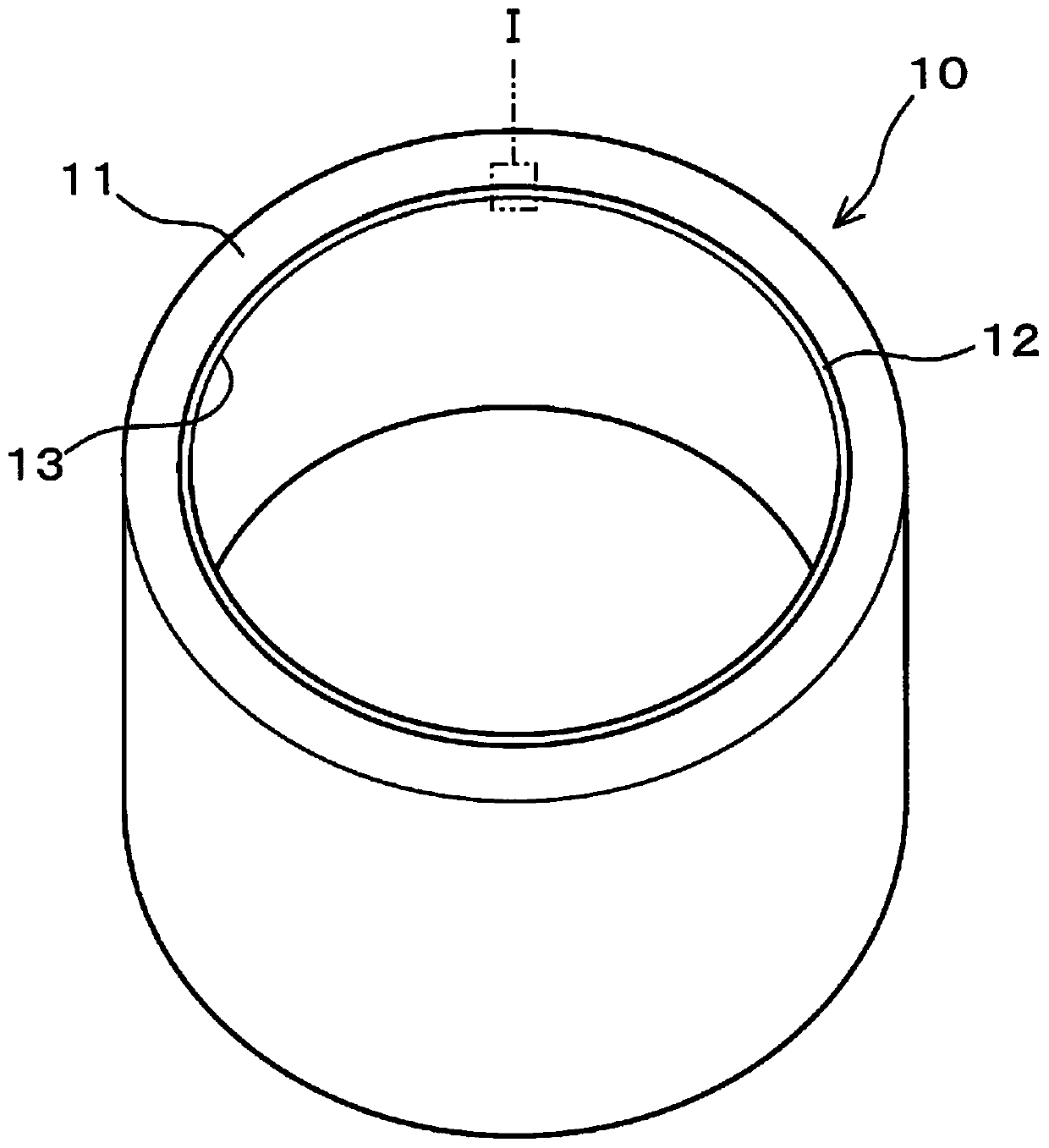

[0027] Such as figure 1 and figure 2 As shown, the sliding member 10 has an inner metal layer 11 and a bearing alloy layer 12 . The inner metal layer 11 is formed of, for example, Fe, steel typified by low carbon steel, or a copper alloy. The bearing alloy layer 12 is stacked on one end surface side of the back metal layer 11 . For example, if figure 2 As shown, in the case where the back metal layer 11 is formed in a cylindrical shape, the bearing alloy layer 12 is provided on the inner peripheral surface side of the back metal layer 11 . The bearing alloy layer 12 has a sliding surface 13 formed on the end surface opposite to the inner metal layer 11 . The sliding surface 13 slides with an unillustrated target member.

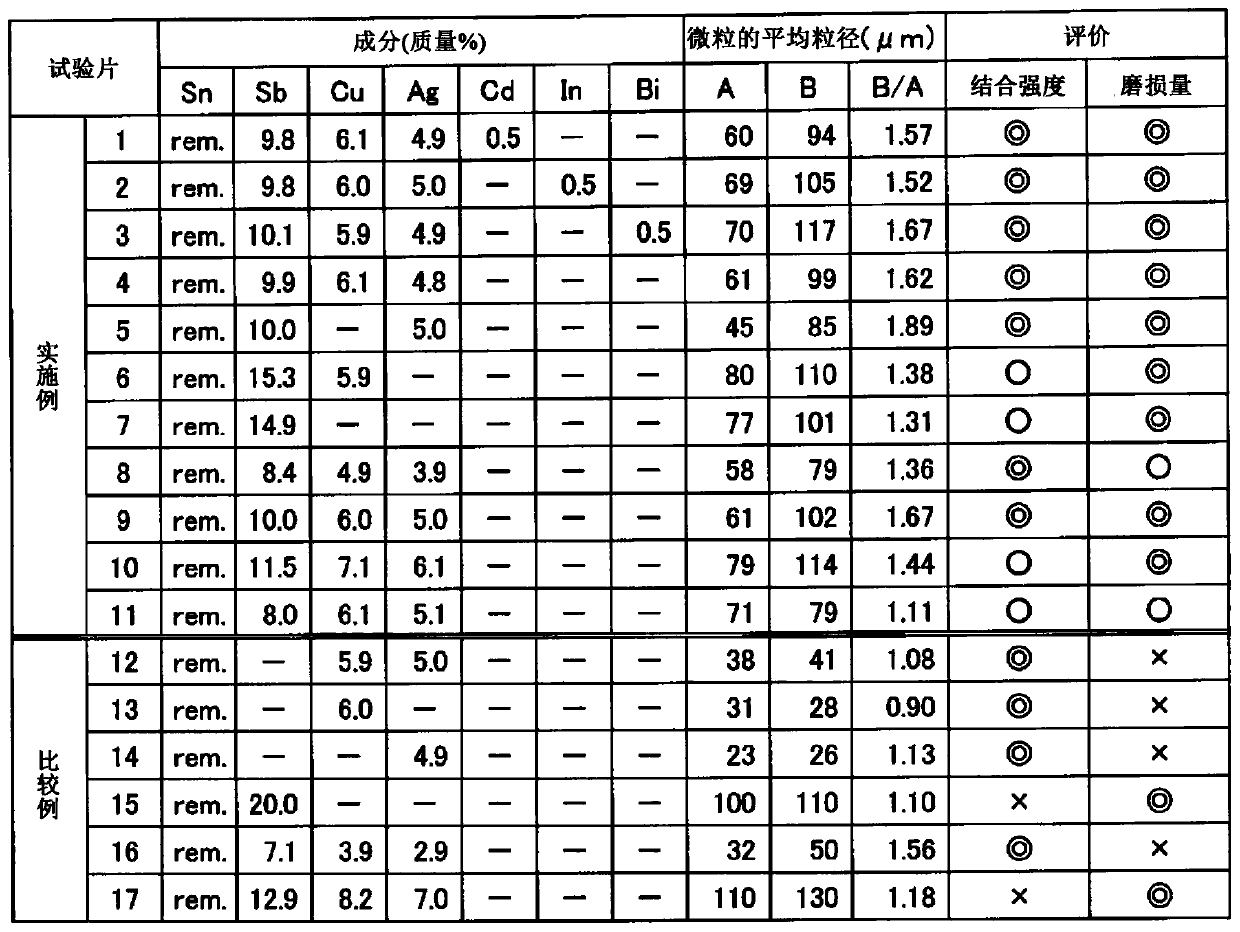

[0028] The bearing alloy layer 12 is formed of a Sn alloy mainly composed of Sn. Bearing alloy layer 12 in as figure 1 The structure shown contains i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com