Non-supported catalyst pulp, preparation method and application thereof

A catalyst slurry and supported technology, which is applied in the field of fuel cell and solid polymer water electrolysis cell catalyst slurry and its preparation, can solve the problems of no catalyst activity and great influence on catalyst activity, and achieve a simple and fast preparation process. , the effect of accelerating the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

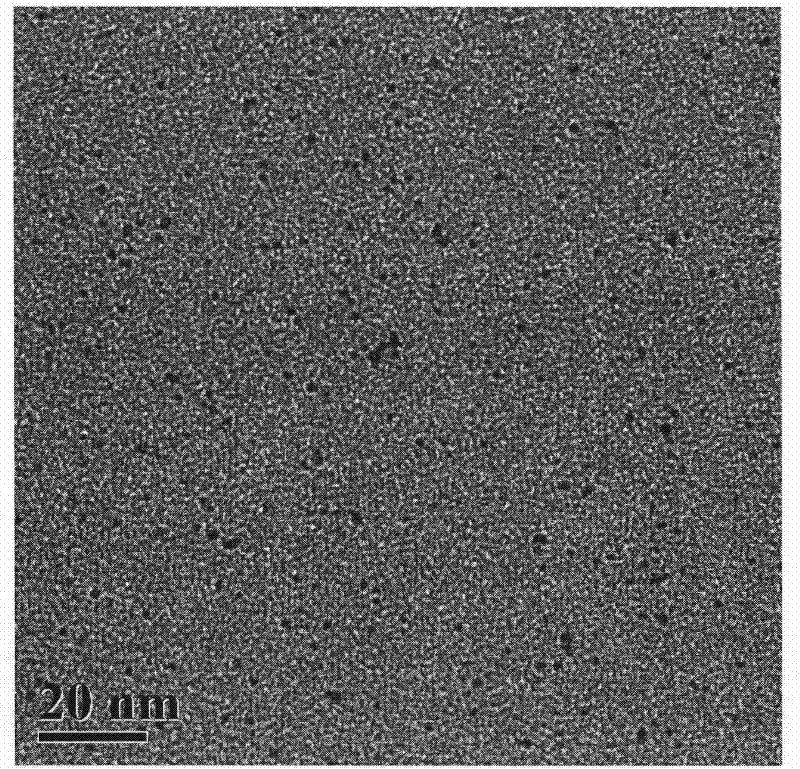

[0043] Accurately weigh 400 mg of Nafion solution with a mass concentration of 5%, add it to the mixed solution of ethanol and water, the mass ratio of ethanol and water is 1:1, stir for 6 minutes, add 80 mg of Ir in H 2 IrCl 6 Continue to stir the solution for 30 minutes, add NaOH to adjust the pH of the solution to 13, transfer the solution to a pressure-resistant stainless steel reactor, and rapidly raise the temperature to 150°C at an average heating rate of 15°C / min under airtight conditions to control the reaction The temperature was 150° C., and the reaction time was 5 hours to finally obtain a colloidal solution of Ir nanoparticles modified by the proton-conducting polymer. The obtained colloidal solution adopts dialysis bag in the mixed solution of ethanol and water (wherein the mass fraction of ethanol and water is 95% and 5% respectively) and dialysis process removes organic by-product and impurity ion, and the cut-off molecular weight of dialysis bag is 14000Da , ...

Embodiment 2

[0055] Accurately weigh 600 mg of Nafion solution with a mass concentration of 5%, add it to the mixed solution of ethanol and water, the mass ratio of ethanol and water is 1:1, after stirring for 6 minutes, add 80 mg of Ir in H 2 IrCl 6 and RuCl containing 20 mgRu 3Continue to stir the solution for 30 minutes, add NaOH to adjust the pH value of the solution to 13.5, transfer the solution to a pressure-resistant stainless steel reactor, and rapidly raise the temperature to 160°C at an average heating rate of 15°C / min under airtight conditions to control the reaction The temperature was 160° C., and the reaction time was 5 hours to finally obtain a colloidal solution of IrRu nanoparticles modified by the proton-conducting polymer. The obtained colloidal solution adopts dialysis bag in the mixed solution of Virahol alcohol and water (wherein the mass fraction of Virahol and water is respectively 95% and 5%) and dialysis process removes organic by-product and impurity ion, and t...

Embodiment 3

[0059] Accurately weigh 600 mg of Nafion solution with a mass concentration of 5%, add it to the mixed solution of ethanol and water, the mass ratio of ethanol and water is 1:1, after stirring for 6 minutes, add 80 mg of Ir in H 2 IrCl 6 and Na containing 20mgSe 2 SeO 3 Continue to stir the solution for 30 minutes, add NaOH to adjust the pH value of the solution to 12.5, transfer the solution to a pressure-resistant stainless steel reactor, and rapidly raise the temperature to 150°C at an average heating rate of 15°C / min under airtight conditions to control the reaction The temperature is 150° C., and the reaction time is 5 hours to finally obtain a colloidal solution of IrSe nanoparticles modified by the proton-conducting polymer. The obtained colloidal solution adopts dialysis bag in the mixed solution of ethanol and water (wherein the mass fraction of ethanol and water is 96% and 4% respectively) and dialysis process removes organic by-product and impurity ion, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com