Unsupported fuel cell catalyst slurry and preparation method thereof

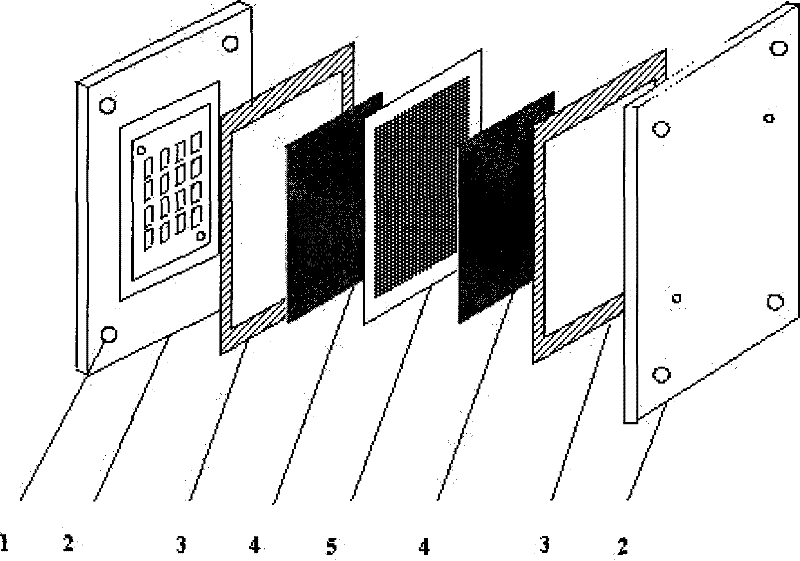

A catalyst slurry and fuel cell technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of reducing the effective active area of catalysts, increasing resistance, reducing electron conduction channels, etc., and reaching the catalytic layer Orderly structure and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

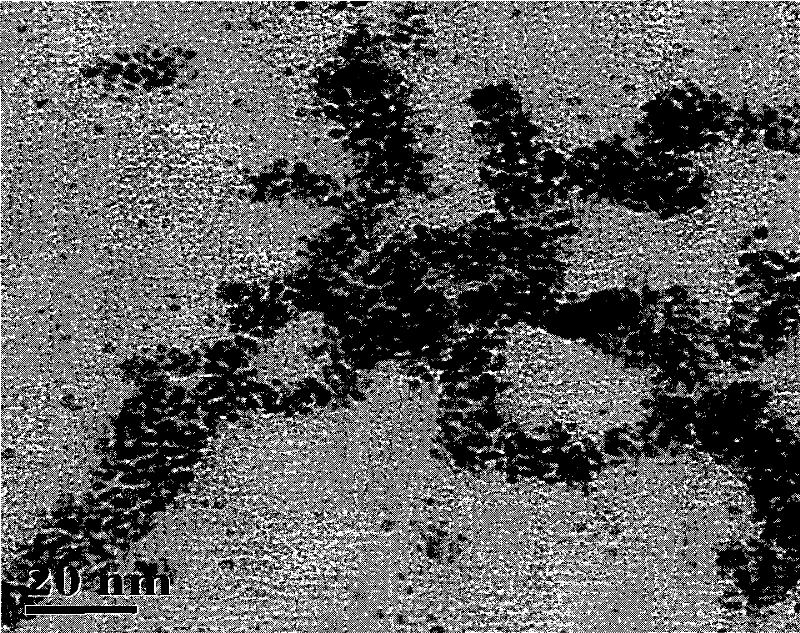

[0037] Accurately weigh 400 mg of Nafion solution with a mass concentration of 5%, add it to the mixture of propanol and water, the mass ratio of propanol to water is 1:1, stir for 6 minutes, add 80 mg of Pt in H 2 PtCl 6 The solution continued to stir for 30 minutes, adding NaOH to adjust the pH of the solution to 9 and 5ml of formaldehyde, stirring and heating to reflux at 90°C to keep the pH of the solution at 9, and reacting for 60 minutes to finally obtain a stable dark brown Pt colloidal solution. The obtained colloidal solution adopts dialysis bag in the mixed solution of propanol and water (wherein the mass fraction of propanol and water is respectively 95% and 5%) dialysis treatment removes organic by-product and impurity ion, and the cut-off molecular weight of dialysis bag is 14000Da , to obtain a catalyst slurry for preparing a fuel cell catalyst layer, wherein the mass fraction of the metal catalyst is 1%.

[0038] Prepare fuel cell electrodes with the prepared c...

Embodiment 2

[0048] Accurately weigh 800 mg of SPEEK solution with a mass concentration of 5%, add it into the mixture of ethanol and water, the mass ratio of ethanol and water is 2:1, stir for 10 minutes, add 80 mg of Pt in H 2 PtCl 6 The solution was stirred for 30 minutes and Na was added 2 CO 3 Adjust the pH of the solution to 10 and 5ml of sodium citrate, stir and heat to reflux at 85°C, keep the pH of the solution at 10, react for 50 minutes, and finally obtain a stable dark brown Pt colloidal solution. The obtained colloidal solution adopts dialysis bag in the mixed solution of ethanol and water (wherein the mass fraction of ethanol and water is respectively 94% and 6%) and dialysis process removes organic by-product and impurity ion, and the cut-off molecular weight of dialysis bag is 7000Da , to obtain a catalyst slurry for preparing a fuel cell catalyst layer, wherein the mass fraction of the metal catalyst is 1.5%.

[0049] The preparation of MEA, single cell assembly and tes...

Embodiment 3

[0051] Accurately weigh 300 mg of SPEEK solution with a mass concentration of 5%, add it to the mixture of methanol and water, the mass ratio of methanol to water is 0.8:1, stir for 8 minutes, add 60 mg of Pt in H 2 PtCl 6 solution and H containing 20mgIr 2 IrCl 6 The solution was stirred for 30 minutes, and NaOH was added to adjust the pH of the solution to 10 and 5ml of acetaldehyde, stirred and heated to reflux at 90° C. to keep the pH of the solution at 10, and reacted for 40 minutes to finally obtain a stable dark brown PtIr colloidal solution. The obtained colloidal solution adopts dialysis bag in the mixed solution of methanol and water (wherein the mass fraction of methanol and water is respectively 93% and 7%) dialysis treatment removes organic by-product and impurity ion, and the cut-off molecular weight of dialysis bag is 14000Da , to obtain a catalyst slurry for preparing a fuel cell catalyst layer, wherein the mass fraction of the metal catalyst is 3%.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com