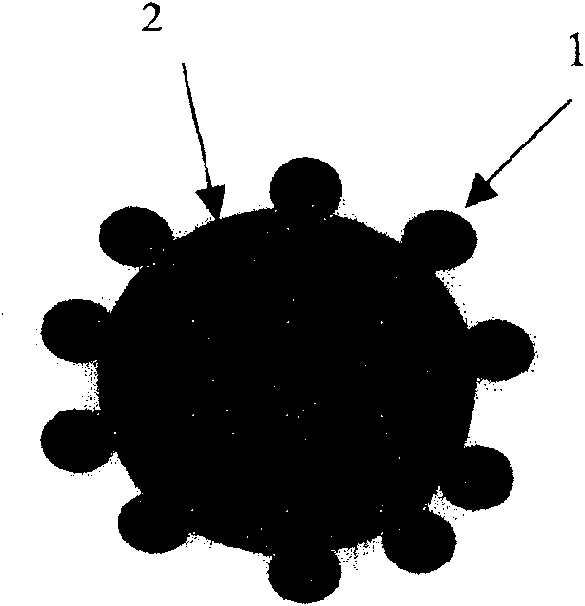

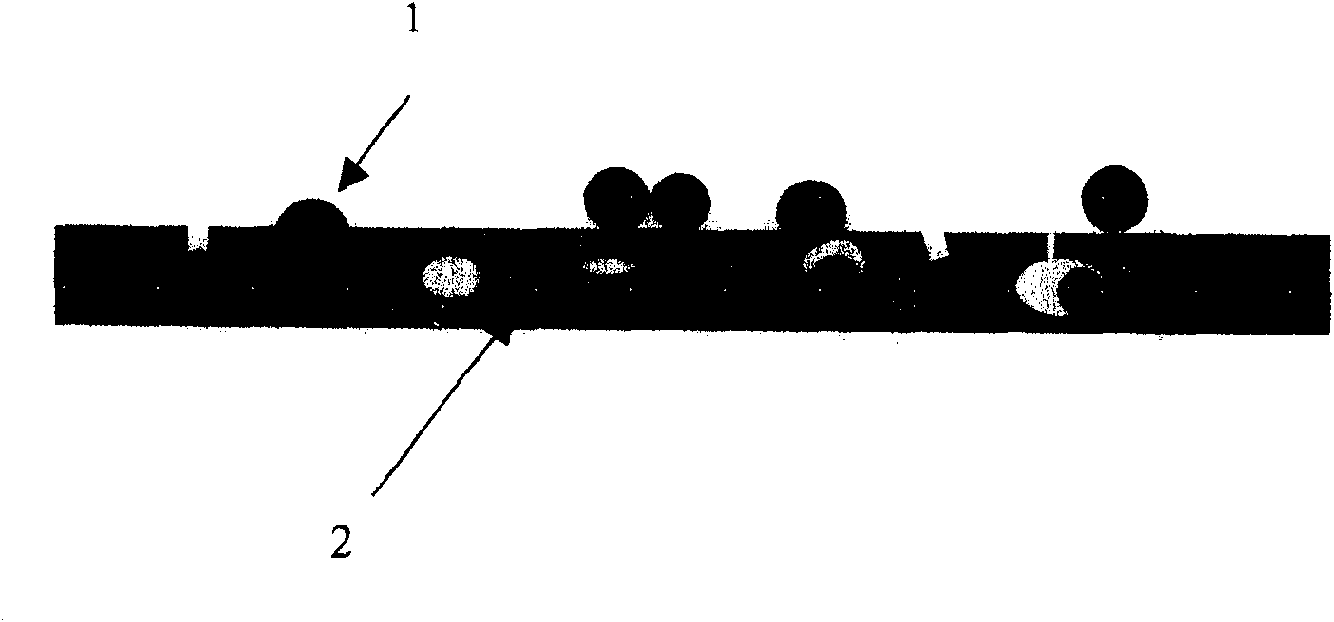

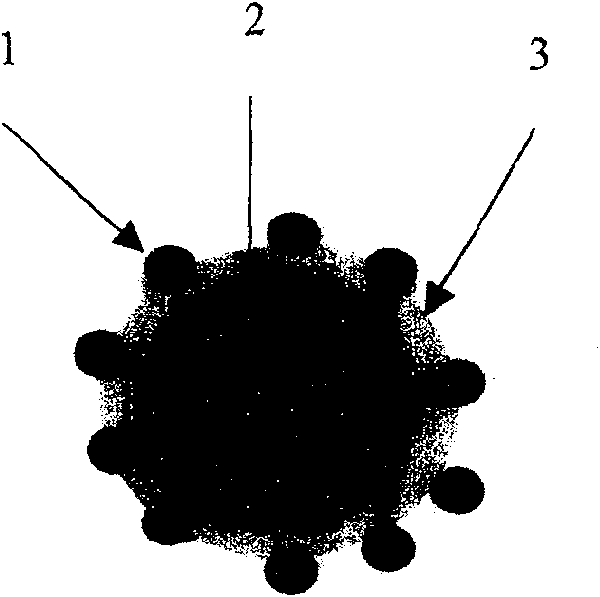

Proton high polymer modified fuel cell catalyst using carbon as carrier and its preparation

A technology for proton-conducting polymers and fuel cells, which can be used in catalyst activation/preparation, physical/chemical process catalysts, catalyst carriers, etc., and can solve problems such as reduced Pt utilization, difficulty in entering proton exchange resins, and lack of bonding. , to achieve the effect of improving the utilization rate and improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Get 80 milligrams of carbon black XC-72 (specific surface area is 250 square meters per gram), join in the mixed solution of 20 milliliters of methanol and water, the mass ratio of methanol and water is 1: 1, ultrasonic (R-S150 ultrasonic Cell pulverizer) was dispersed for 5-10 minutes, then added to 100 milliliters of alcoholic water (the mass ratio of methanol and water was 1: 1) mixed solution and stirred, then added 2 milliliters of Nafion with a mass concentration of 5% in the mixed solution ( Perfluorosulfonic acid resin) solution, continue to stir for 2 hours, add the H containing 32 mg of Pt 2 PtCl 6 And continue to stir for 20 minutes, adjust the pH of the solution to 8-9 with NaOH, and heat to reflux at 90° C. for 50 minutes to prepare the catalyst of the present invention. Among them, the average particle diameter of Pt particles is 2.5 nanometers, and the dispersibility is good.

[0034]Preparation of the fuel cell core chip CCM: Add the prepared catalyst ...

Embodiment 2

[0037] Get 80 mg of carrier mesoporous carbon microspheres with a pore size of 3 to 6 nanometers, add them to a mixed solution of 20 ml of ethanol and water, the mass ratio of ethanol and water is 100:1, and ultrasonically (R-S150 ultrasonic cell pulverizer ) dispersed for 5 to 10 minutes, then added to 100 milliliters of alcoholic water (the mass ratio of ethanol and water is 100:1) and stirred in the mixed solution, then added 20 milliliters of Nafion solution with a mass concentration of 5% in the mixed solution, and continued to stir 2 h, add 32 mg of Pt in H 2 PtCl 6 The solution was stirred continuously for 20 minutes, the pH of the solution was adjusted to 13 with NaOH, and heated to reflux at 90° C. for 50 minutes to obtain the electrocatalyst of the present invention. Among them, the average particle diameter of Pt particles is 3.5 nanometers, and the dispersibility is good.

[0038] The preparation process of the fuel cell core chip CCM, single cell assembly and te...

Embodiment 3

[0040] Get 80 milligrams of carrier nano-graphite balls, the particle diameter is 40~55 nanometers, join in the mixed solution of 20 milliliters of ethanol and water, the mass ratio of ethanol and water is 0.5: 1, ultrasonic (R-S150 ultrasonic cell pulverizer ) dispersed for 5 to 10 minutes, then added to 100 milliliters of alcohol water (the mass ratio of ethanol and water is 0.5: 1) mixed solution and stirred, then added 10 milliliters of SPEEK solution with a mass concentration of 5% in the mixed solution, and continued to stir 2 h, add 32 mg of Pt in H 2 PtCl 6 继 Continue stirring for 20 minutes, adjust the pH of the solution to 9 with NaOH, and heat to reflux at 90° C. for 50 minutes to obtain the electrocatalyst of the present invention. Among them, the average particle diameter of Pt particles is 3 nanometers, and the dispersibility is good.

[0041] The preparation process of the fuel cell core chip CCM, single cell assembly and test conditions are the same as in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com