Spherical cobalt oxalate powder and production method thereof

A manufacturing method, technology of cobalt oxalate powder, applied in the field of metallurgy and chemical industry, to achieve the effect of good shape, uniform distribution, controllable shape and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

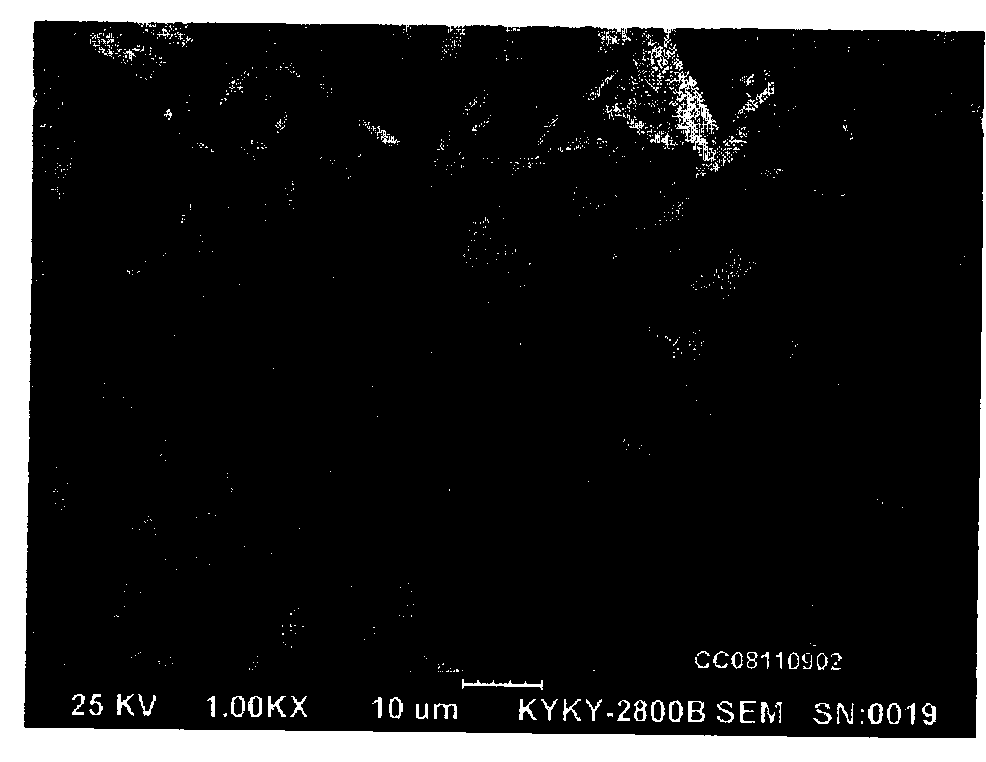

[0029] Produced 0.5MCoCl 2 solution and 0.5M K 2 C 2 o 4 solution, before the reaction, equimolar amounts of each solution were preheated to 25°C, and K 2 C 2 o 4 Join CoCl 2 In the solution, adjust the pH value to 6-7, stir at constant temperature, react for 15-30 minutes, separate and filter the precipitated powder from the solution, wash with clean water, and dry at 100-150°C for 4 hours to obtain spherical cobalt oxalate with a particle size of about 7um , suitable for general powder metallurgy industry, battery industry, etc.

Embodiment 2

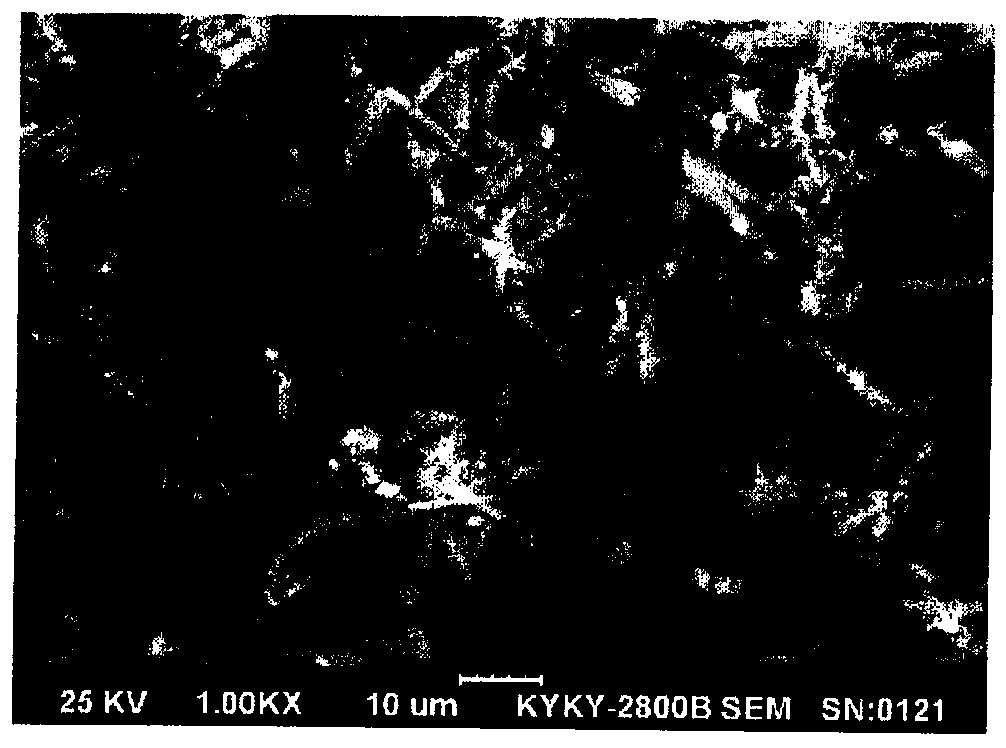

[0031] Produced 0.5MCoCl 2 solution and 0.5M K 2C 2 o 4 solution, before the reaction, equimolar amounts of each solution were preheated to 40°C, and K 2 C 2 o 4 Join CoCl 2 In the solution, adjust the pH value to 6-7, stir at constant temperature, react for 15-30 minutes, separate and filter the precipitated powder from the solution, wash with clean water, and dry at 100-150°C for 4 hours to obtain spherical cobalt oxalate with a particle size of 6um , suitable for general powder metallurgy industry, battery industry, etc.

Embodiment 3

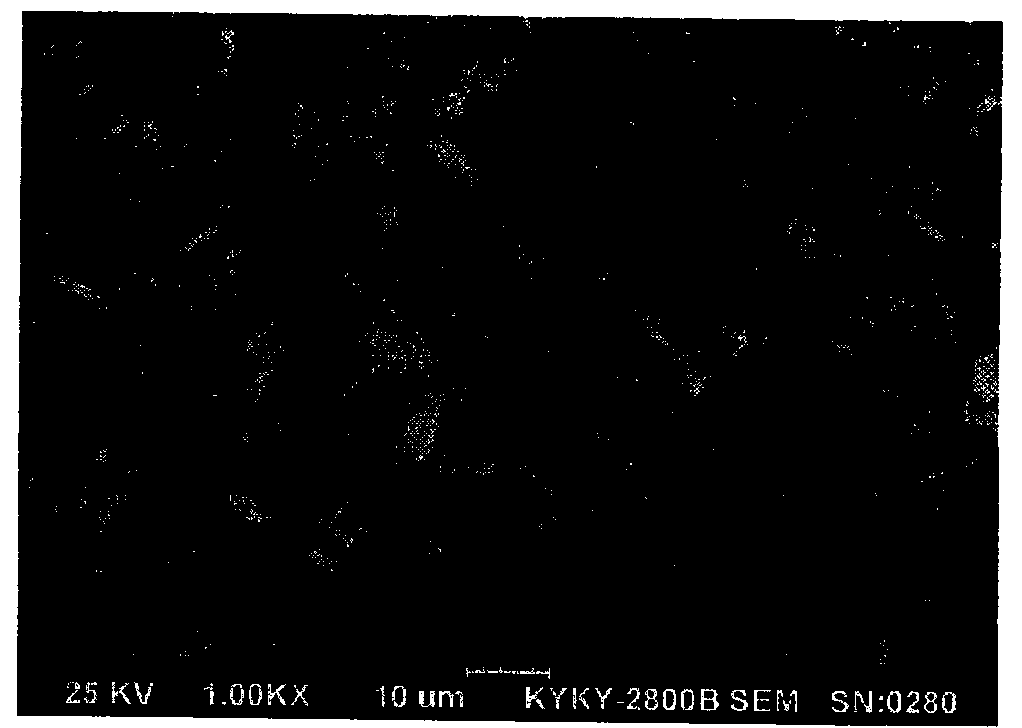

[0033] 1MCoCl 2 solution and 1M K 2 C 2 o 4 solution, before the reaction, equimolar amounts of each solution were preheated to 25°C, and K 2 C 2 o 4 Join CoCl 2 In the solution, adjust the pH value to 6-7, stir at constant temperature, react for 15-30 minutes, separate and filter the precipitated powder from the solution, wash with clean water, and dry at 100-150°C for 4 hours to obtain spherical oxalic acid with a particle size of about 10um Cobalt, suitable for general powder metallurgy industry, battery industry, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com