Aqueous sealing agent for zinc-based micro-coating and preparation method thereof

A water-based sealant and micro-coating technology, applied in the direction of metal material coating process, can solve problems such as poor high temperature resistance, strong odor, hidden safety hazards, etc., to improve acid and alkali resistance and high temperature resistance, good corrosion resistance, The effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

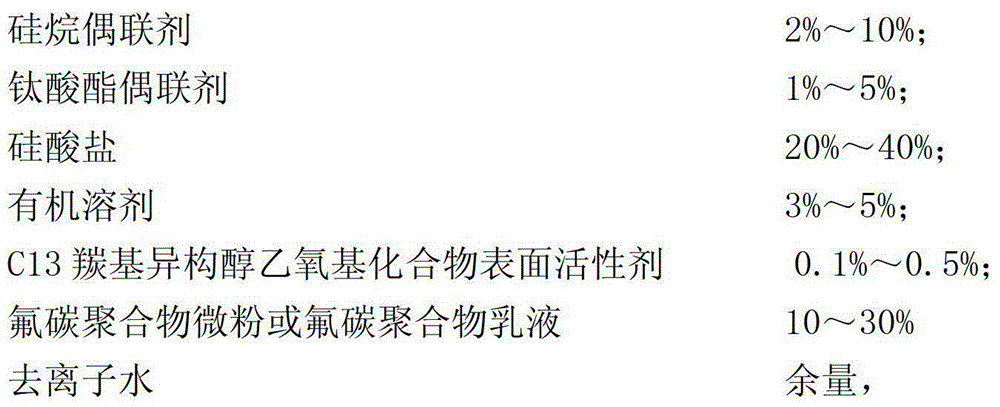

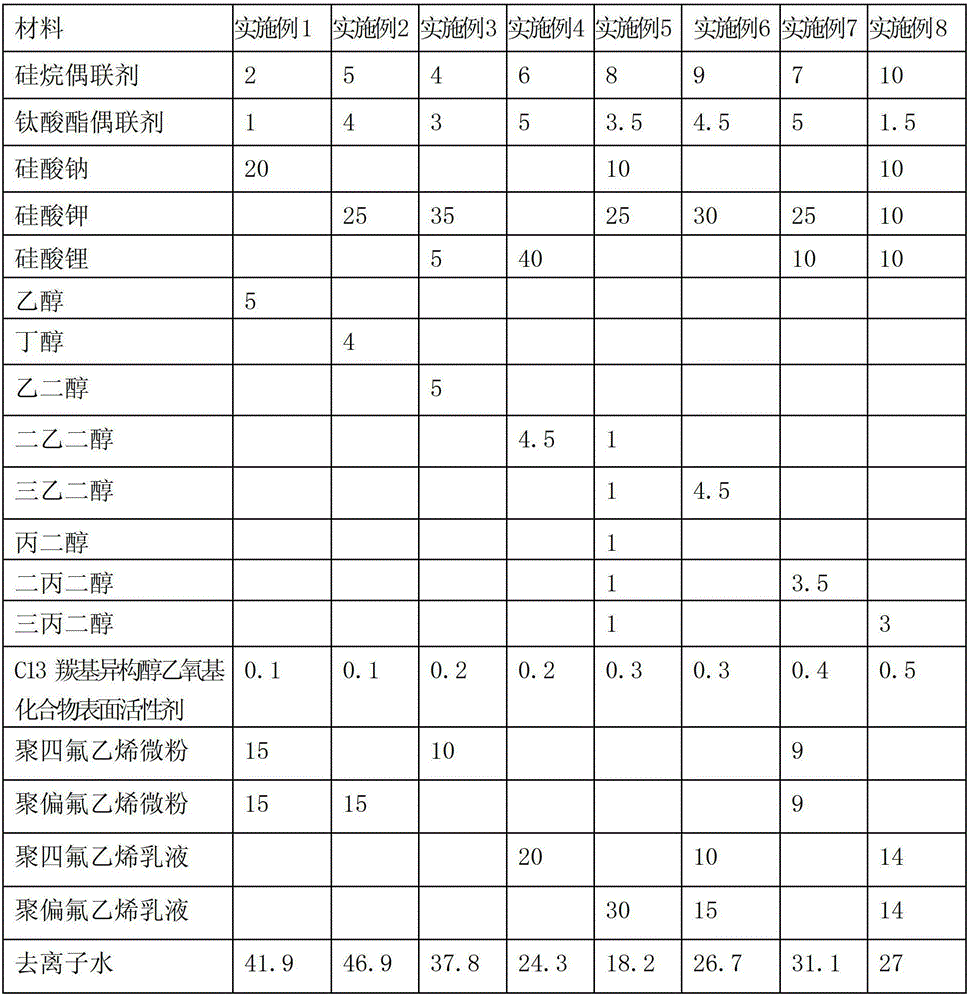

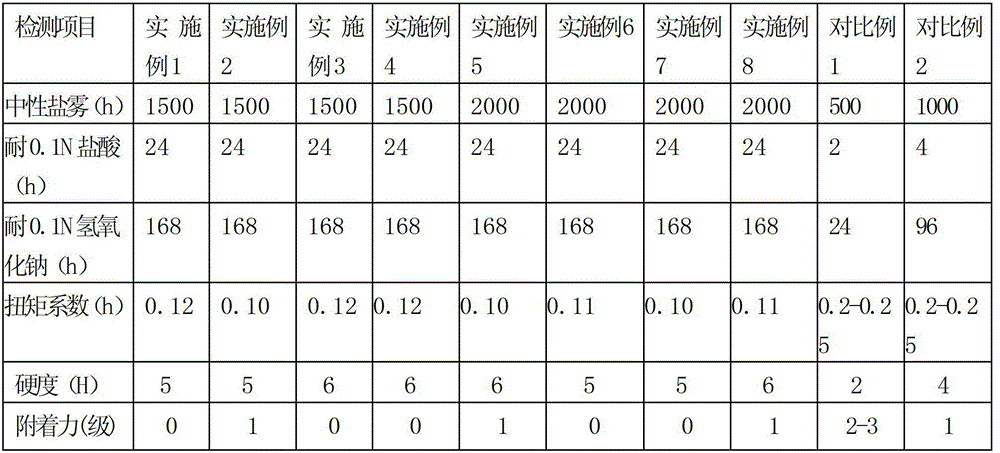

[0014] The water-based sealing agent for zinc-based micro-coating of the present invention, its raw material is composed of components with the following mass percentages: 2% to 10% of silane coupling agent, 1% to 5% of titanate coupling agent , 20%~40% silicate, 3%~5% organic solvent, 0.1%~0.5% C13 carbonyl isomer alcohol ethoxylate surfactant, 10~30% fluorocarbon polymer powder or Fluorocarbon polymer emulsion and the balance of deionized water, the particle size of the fluorocarbon polymer micropowder is 10-20 microns, and the above raw materials can be purchased in the market.

[0015] The organic solvent of the present invention is an alcohol organic solvent, and the alcohol organic solvent adopts one or both of ethanol, butanol, ethylene glycol, diethylene glycol, triethylene glycol, propylene glycol, dipropylene glycol or tripropylene glycol. More than one mixed alcohol, the mass percentage is not limited when mixing, and the storage stability of the water-based sealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com