Zirconium metal complex of furan aldehyde (ketone) hydrazone as well as preparation method and application of zirconium metal complex

A technology of metal complexes and furan aldehydes, which is applied in the field of zirconium metal complexes, can solve problems such as unsuitable solution polymerization processes, and achieve the effects of simple and easy preparation methods, high yields, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

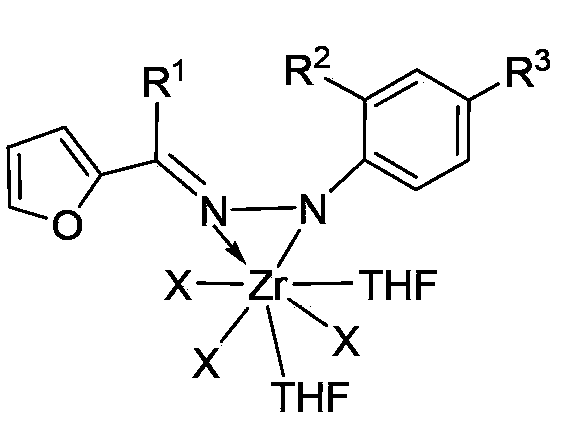

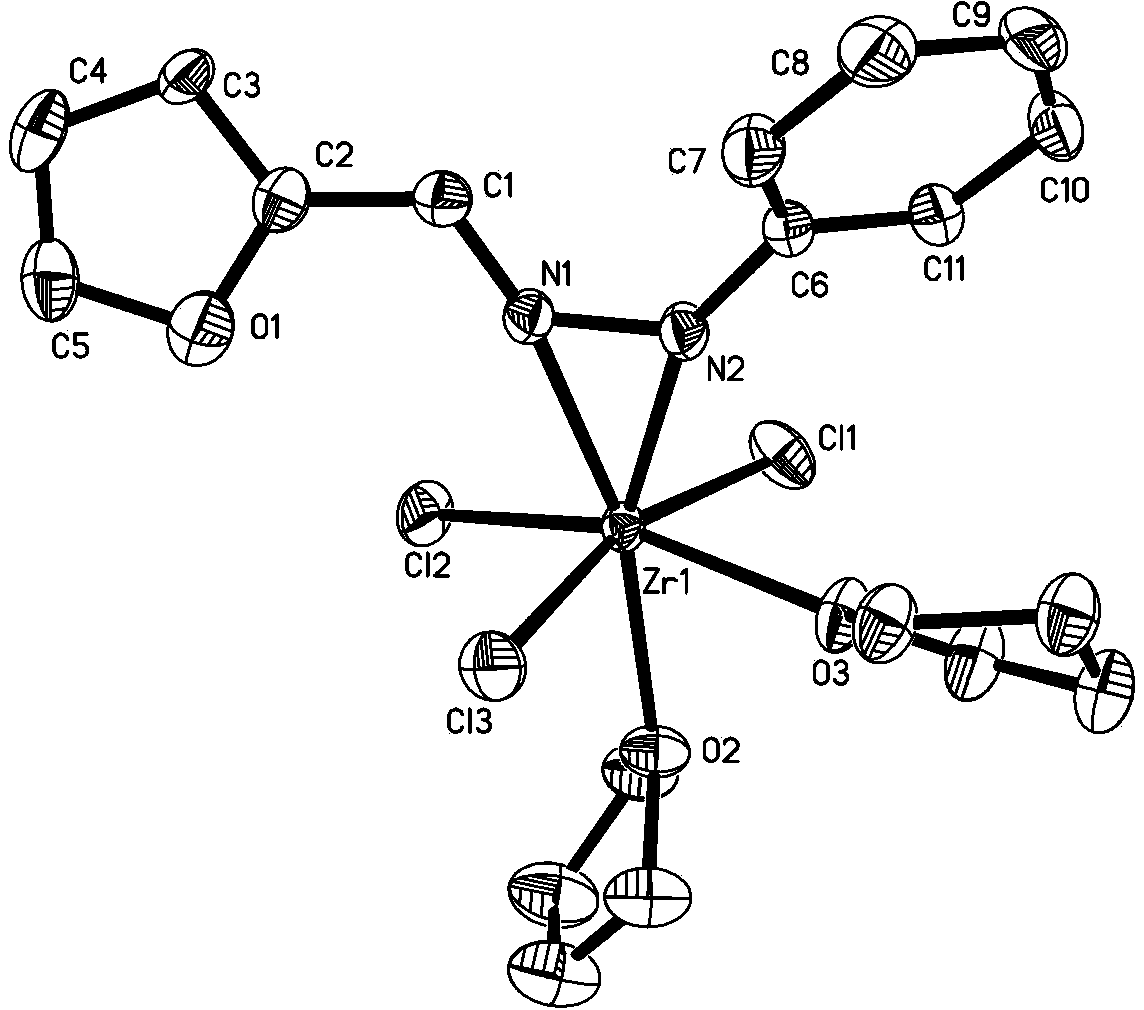

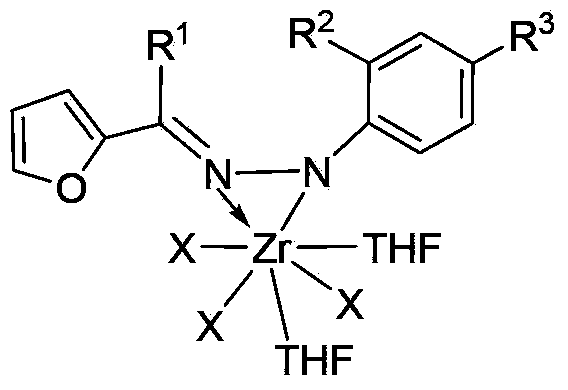

[0023] The preparation of embodiment 1 zirconium metal complex

[0024] Preparation of Ligand 2-furylcarbaldehyde phenylhydrazone:

[0025] Dissolve 2-furylcarbaldehyde (1.92g, 20mmol) in 20ml of ethanol, add an equimolar amount of phenylhydrazine (2.16g, 20mmol) dropwise at 0°C, the reaction solution gradually rises to room temperature, and more Pale yellow solid, continue to stir the reaction overnight. The ethanol was removed by suction filtration, and the yellow solid was washed with ether to obtain a light yellow solid, which was the ligand 2-furaldehyde phenylhydrazone (2.87 g), with a yield of 77%.

[0026] Preparation of zirconium metal complexes of tetrahydrofuran-coordinated 2-furylaldehyde phenylhydrazone trichloride:

[0027] At 0°C, add an equimolar amount of LDA (0.27g, 2.52mmol) to a solution of the ligand compound 2-furylaldehyde phenylhydrazone (0.47g, 2.52mmol) in about 25ml of ether to obtain a yellow suspension Gradually warm to room temperature and stir...

Embodiment 2

[0028] The application of embodiment 2 complex as catalyst in catalytic ethylene polymerization

[0029] Aggregation condition selection:

[0030] At 10atm, when the molar ratio of MAO:catalyst is 1000:1, the temperature is changed, and the activity at 30°C, 50°C, 70°C, and 90°C is tested respectively, which are 0.96×10 5 , 1.52×10 5 , 1.96×10 5 , 0.44×10 5 gPE / mol(Zr) h. When the temperature is 70°C, test the MAO respectively: the molar ratio of the catalyst is 500:1, 1500:1, and the activity when 2000:1 is respectively 0.52×10 5 , 1.64×10 5 , 1.52×10 5 gPE / mol(Zr) h.

[0031] 1: The polymerization of ethylene is carried out in a stainless steel pressure kettle with a volume of 250ml. The pressure kettle is connected with a buffered ethylene cylinder, which can continuously replenish ethylene through a spiral steel pipe, so as to maintain a constant pressure during the polymerization reaction (under 10atm pressure) . After the polymerization kettle is fully dried, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com