Urea sulfate reactor and application thereof

A technology of reactor and urea sulfate, which is applied in the field of compound fertilizer, can solve the problems of high investment and operation cost, high repair and maintenance cost, high safety level requirements, etc., and achieve the effect of light weight, simple structure and high granulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

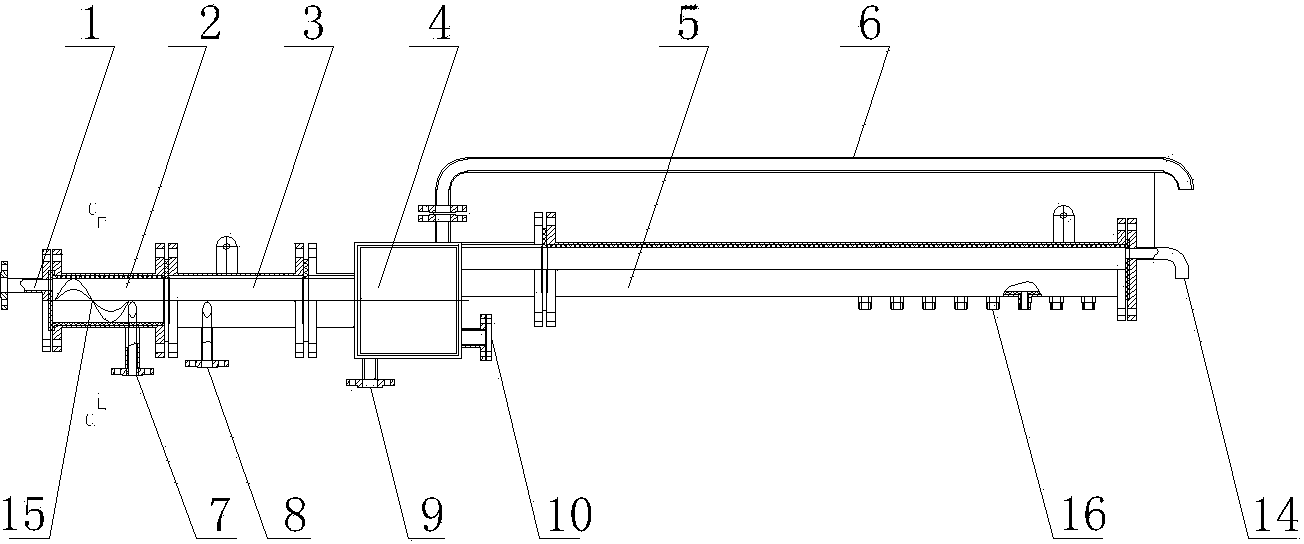

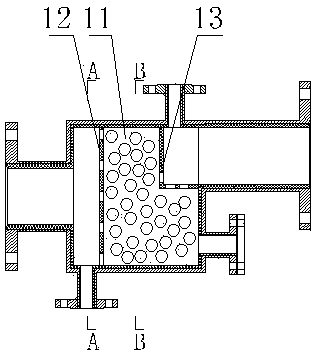

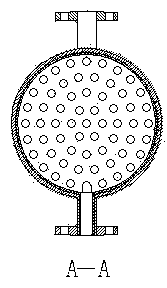

[0025] Such as Figure 1 to Figure 5 As shown, the urea sulfuric acid reactor is located in the granulator, which includes five parts: diversion section 2, mixed acid section 3, fixed bed reaction section 4, spraying pipe 5 and atomizing nozzle, and the above five parts are arranged in sequence and between each other It is fixedly connected by a flange; the urea solution pipeline is connected to the urea solution inlet port 1 of the reactor, and the urea solution inlet port 1 is located at the end side of the diversion section 2; the concentrated sulfuric acid solution pipeline is connected to the concentrated sulfuric acid inlet port 7 of the reactor , the concentrated sulfuric acid inlet port 7 is located on the side wall at the end of the diversion section 2; the fixed bed reaction section 4 is a chamber, and the chamber is separated by orifice plate I12 and orifice II13 to form a packing layer 11, the packing layer 11 Connected with the filling port 10, several through hol...

Embodiment 2

[0028] 50 (30-10-10)% compound fertilizer production process, including the following steps:

[0029] (1) Install the urea sulfuric acid reactor in the granulator, connect the urea solution pipeline to the urea solution inlet port 1 of the reactor, and connect the concentrated sulfuric acid solution pipeline to the concentrated sulfuric acid inlet port 8 of the reactor, and the solid in the granulator Materials include urea 200kg, ammonium bicarbonate 47kg, monoammonium phosphate 208kg, potassium chloride 170kg;

[0030] (2) Put 20kg of sulfuric acid and 374kg of urea solution (95°C, containing 355kg of urea) into the urea sulfate reactor through the sulfuric acid pump and the urea solution pump to react. During the reaction, a large amount of reaction heat, high temperature and viscous urea sulfate will be generated. Liquid, high-temperature molten urea and high-temperature and high-pressure steam, among which high-temperature viscous urea sulfate liquid and high-temperature ...

Embodiment 3

[0033] 54 (18-18-18)% compound fertilizer production process, including the following steps:

[0034] (1) Install the urea sulfuric acid reactor in the granulator, connect the urea solution pipeline to the urea solution inlet port 1 of the reactor, and connect the concentrated sulfuric acid solution pipeline to the concentrated sulfuric acid inlet port 8 of the reactor, and the solid in the granulator Materials include urea 150kg, ammonium bicarbonate 60kg, monoammonium phosphate 365kg, potassium chloride 285kg;

[0035](2) Put 20kg of sulfuric acid and 126kg of urea solution (97°C, containing 120kg of urea) into the urea sulfate reactor for reaction through the sulfuric acid pump and urea solution pump. During the reaction, a large amount of reaction heat, high temperature and viscous urea sulfate will be generated. Liquid, high-temperature molten urea and high-temperature and high-pressure steam, among which high-temperature viscous urea sulfate liquid and high-temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com