Electrolyte for lithium iron phosphate lithium-ion battery

A lithium-ion battery and lithium iron phosphate technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of limiting the application performance of lithium iron phosphate batteries, unsatisfactory low-temperature rate capacity, and poor high-temperature cycle performance of batteries. Good battery cycle performance, stable room temperature cycle performance, and suitable for low-temperature discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this example, the solvent ethylene carbonate (EC), ethyl acetate (EA) and ethyl methyl carbonate (EMC) are mixed uniformly in a glove box with a humidity of less than 1% in a ratio of 1:1:1 by volume Make non-aqueous organic solvent, then add the mixed lithium salt that 3.1g LiTFSI and 0.233g LiBOB uniformly mix and form, after uniform mixing, get the mixed lithium salt solution that concentration is 1mol / L, wherein the mole of LiTFSI and LiBOB in the mixed lithium salt The ratio is 9:1. After the electrolyte salt is fully dissolved, leave it for 24 hours to obtain the high-low temperature electrolyte solution for lithium iron phosphate battery of the present invention.

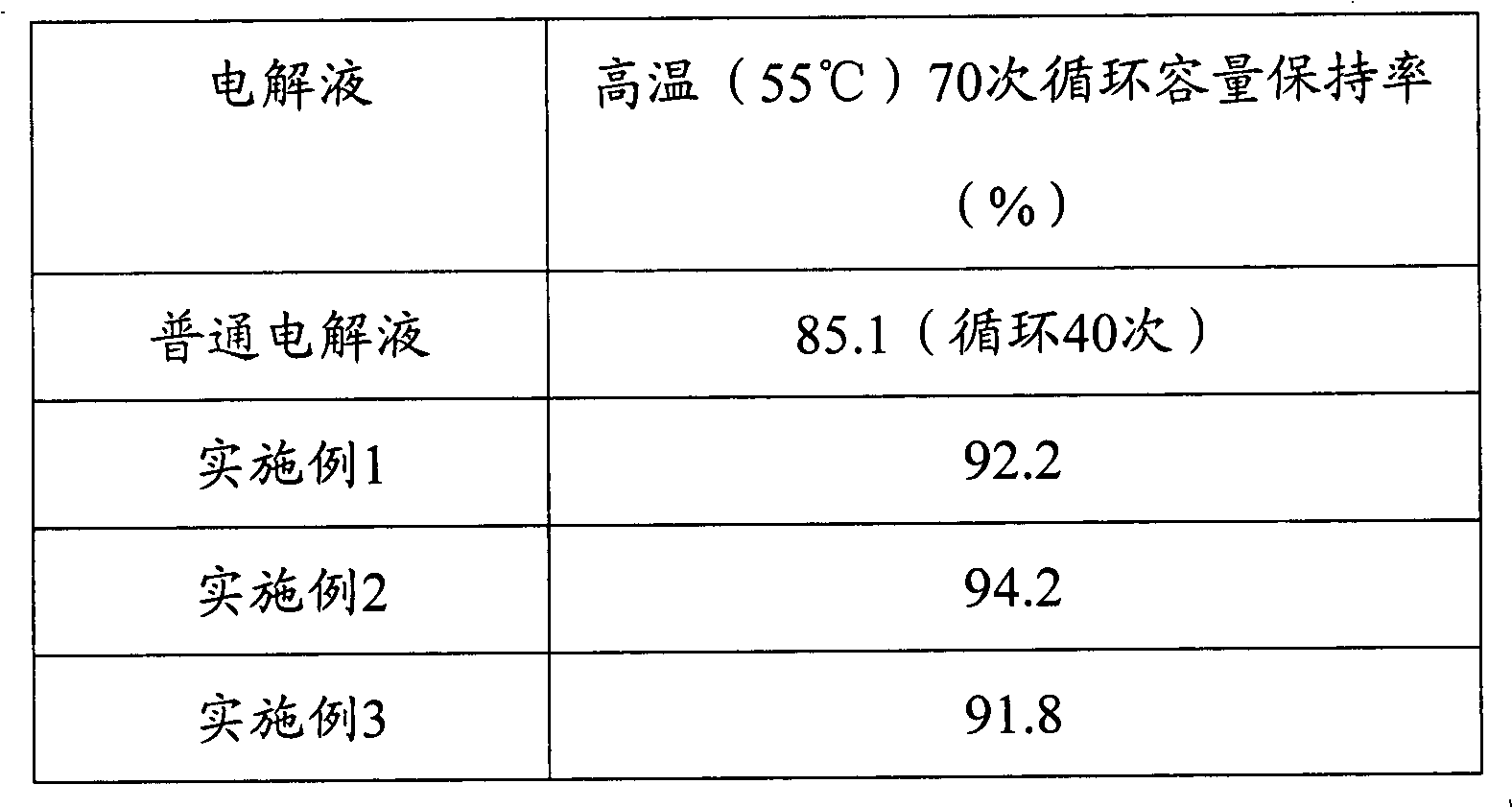

[0016] After testing, using 1C rate discharge, the capacity retention rate of lithium iron phosphate battery at -20°C and -40°C is 64% and 40% respectively; the capacity retention rate after 100 cycles at room temperature is greater than 92.5%; high temperature (55°C ) under the condition of 70 cycl...

Embodiment 2

[0018] In this example, the solvent ethylene carbonate (EC), ethyl acetate (EA), ethyl methyl carbonate (EMC) and r-butyrolactone (GBL) were mixed in a volume ratio of 1:1:1:1 Mix evenly in a glove box with a humidity of less than 1% to make a non-aqueous organic solvent, then add 3.1g LiTFSI and 0.233g LiBOB to form a mixed lithium salt, and mix uniformly to obtain a mixed lithium salt solution with a concentration of 1mol / L , wherein the molar ratio of LiTFSI and LiBOB in the mixed lithium salt is 9:1, after the electrolyte salt is fully dissolved, it is left for 24 hours to obtain the high-low temperature electrolyte solution for lithium iron phosphate battery of the present invention.

[0019] After testing, using 1C rate discharge, the capacity retention rate of lithium iron phosphate battery at -20°C and -40°C is 63% and 43% respectively; the capacity retention rate after 100 cycles at room temperature is greater than 93.2%; high temperature (55°C ) under the condition o...

Embodiment 3

[0021] In this example, the solvent r-butyrolactone (GBL), ethylene carbonate (EC), ethyl acetate (EA) and ethyl methyl carbonate (EMC) were mixed in a volume ratio of 1:1:1:3 Mix evenly in a glove box with a humidity of less than 1% to make a non-aqueous organic solvent, then add 3.1g LiTFSI and 0.233g LiBOB to form a mixed lithium salt, and mix uniformly to obtain a mixed lithium salt solution with a concentration of 1mol / L , wherein the molar ratio of LiTFSI and LiBOB in the mixed lithium salt is 9:1, after the electrolyte salt is fully dissolved, it is left for 24 hours to obtain the high-low temperature electrolyte solution for lithium iron phosphate battery of the present invention.

[0022] After testing, using 1C rate discharge, the capacity retention rate of lithium iron phosphate battery at -20°C and -40°C is 60% and 40% respectively; the capacity retention rate after 100 cycles at room temperature is greater than 92.5%; high temperature (55°C ) under the condition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com