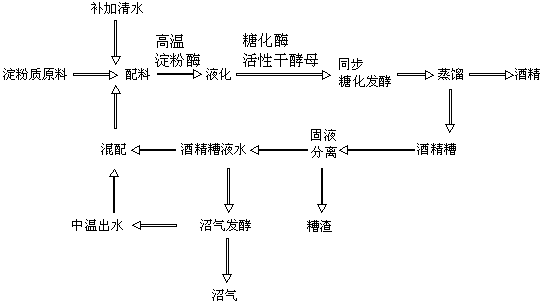

Method for fermenting alcohol by reusing alcohol grain liquid and medium-temperature anaerobic effluent

A technology of anaerobic effluent and fermented alcohol, which is applied in the field of distiller's lees liquid water and medium-temperature anaerobic effluent to reuse fermented alcohol. It can solve the problems of low pH value of slurry, equipment corrosion, environmental climate impact, etc., and improve fermentation efficiency , Improve production efficiency and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention adopts potato, wheat, corn, sorghum, cassava+wheat, potato+corn, sorghum+corn, cassava+sorghum to carry out small experiment respectively, utilizes the experimental means of control variable method, distiller's grain liquid water used in the experiment, and middle temperature exhaust Oxygen effluent comes from large-scale production residues; at the same time, each group of experiments carried out a comparison group test, and the comparison group used a single tap water for mixing, and the other steps remained the same. The experimental results are as follows:

[0024] potato wheat corn sorghum cassava + wheat potato + corn sorghum + corn cassava + sorghum Alcohol degree of mature mash in experimental group 15.27% 14.92% 14.74% 13.85% 15.33% 14.68% 14.20% 14.90% Total sugar in experimental group 2.71% 2.90% 2.14% 2.33% 2.99% 2.73% 2.25% 2.50% Mature alcohol content of the comparison ...

Embodiment 2

[0027] A method for co-reusing fermented alcohol with distiller's grain liquid water and medium-temperature anaerobic effluent, comprising the following process steps:

[0028] (1) Take 500kg of cassava flour, add 560kg of distiller's grain liquid water, add 350kg of medium-temperature anaerobic effluent, and add 45kg of tap water to obtain a slurry pH of 5.0;

[0029] (2) Add 14u / g 干料 60g of high-temperature amylase, stir evenly, heat, and heat at 90°C for 120 minutes to liquefy;

[0030] (3) Rapidly cool down to 34°C, then add 180 u / g干料 Add 500g of glucoamylase, add 1kg of active dry yeast, culture and ferment at 33°C for 60 hours, and the fermentation is over. The volume of the mature fermentation liquid is 809L, the alcohol concentration is 15.15% (v / v), and the finished alcohol is 107kg (95.7% v / v) after distillation. / v);

[0031] (4) Distiller's grains are filtered to obtain 560kg of distiller's residue and distiller's liquid water, of which 270 kg is used for the nex...

example 3

[0036] A method for co-reusing fermented alcohol with distiller's grain liquid water and medium-temperature anaerobic effluent, comprising the following process steps:

[0037] (1) Take 480kg of cassava and corn mixed powder at a ratio of 3:1, add 480kg of distiller's grain liquid water, add 420kg of medium-temperature anaerobic effluent, add 75kg of tap water and 12.5kg of distilled raffinate water, and obtain a slurry pH value of 5.8;

[0038] (2) Add 15u / g 干料 50g of high-temperature amylase, stir evenly, heat, and heat at 95°C for 100 minutes to liquefy;

[0039] (3) Rapidly cool down to 36°C, then add 200 u / g 干料 500g of glucoamylase, after mixing, continue to lower the temperature to 35°C, insert 1kg of active dry yeast, and culture and ferment at a constant temperature of 34°C for 65 hours. The fermentation is completed. The volume of the mature fermentation liquid is 957 kg, and the alcohol concentration is 15.22% (v / v). After distillation and rectification, 109kg (95....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com