Exhaust gas cooler

A technology of exhaust gas cooler and cooling cycle, applied in the direction of exhaust gas recirculation, exhaust gas treatment, exhaust device, etc., can solve the problems of high heat load, limited life of the shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

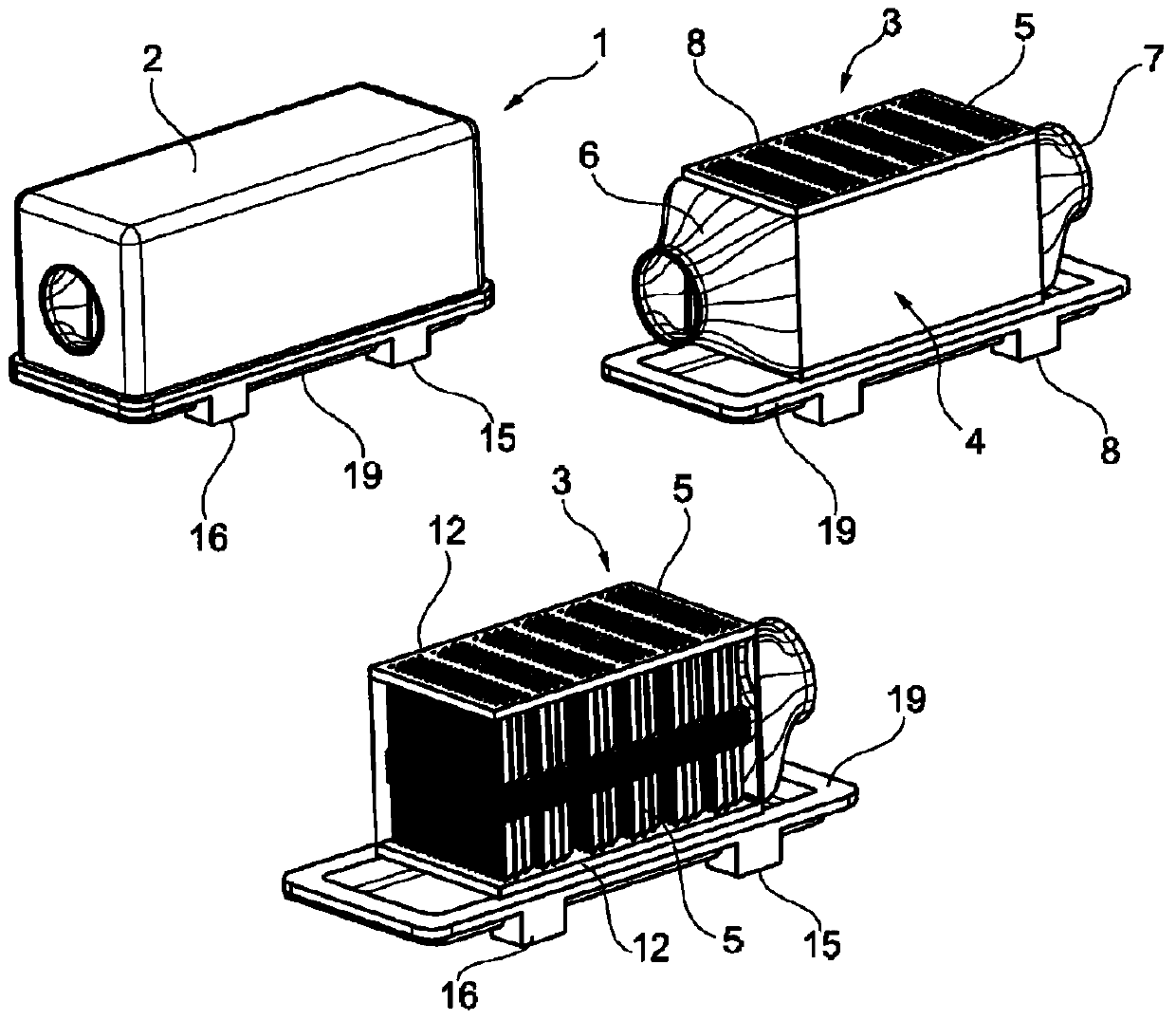

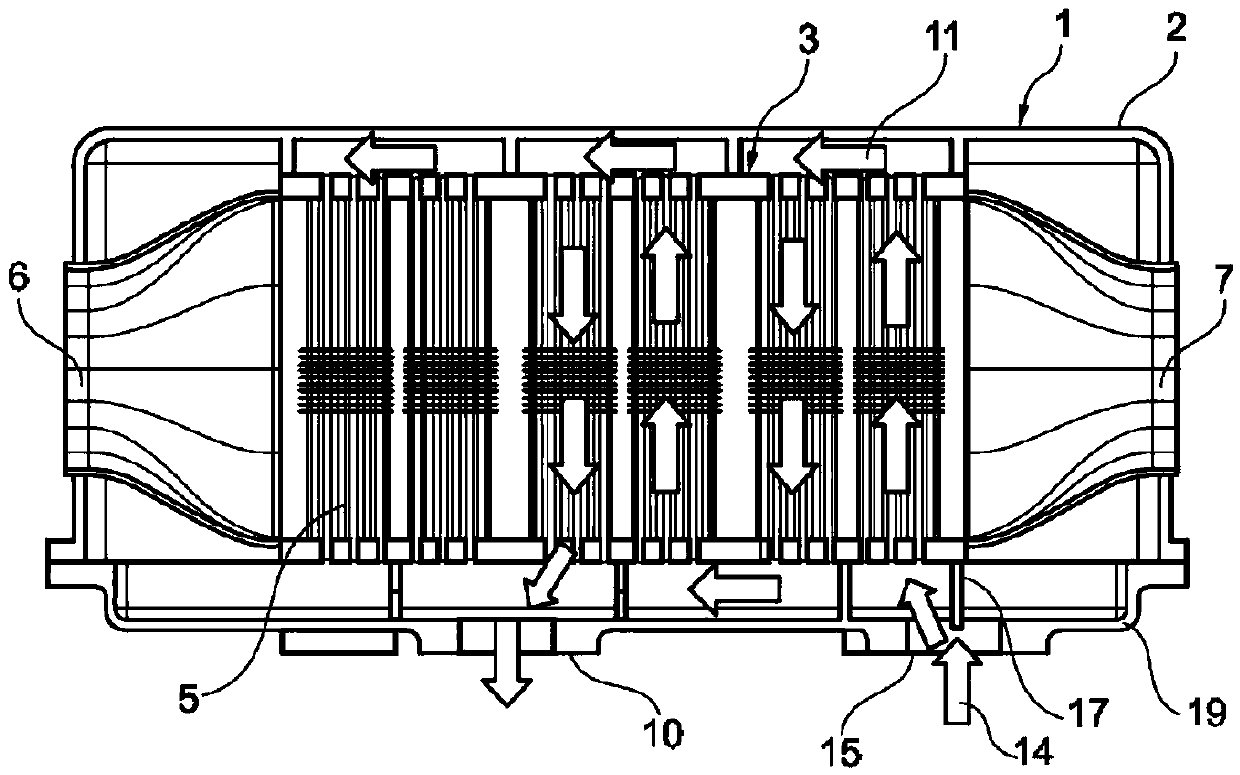

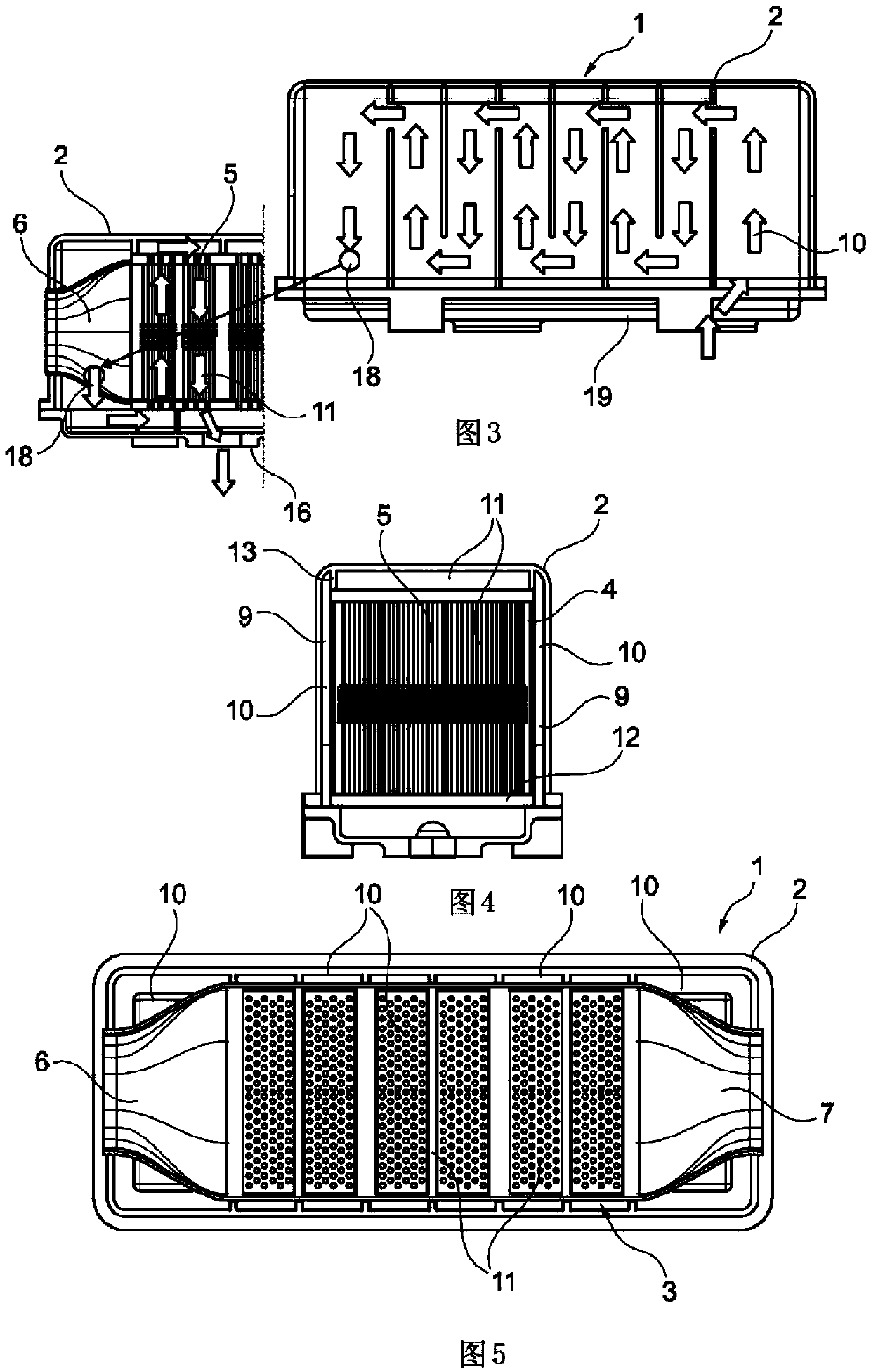

[0019] according to Figure 1-8 , the exhaust gas cooler 1 according to the invention has a housing 2 with a heat exchanger insert 3 arranged therein. The heat exchanger insert 3 has a plurality of tubes 5 around which the exhaust gas flows transversely in the inner shell 4 and in which tubes the cooling liquid of the first circuit 11 flows. The inner shell 4 generally has an inlet diffuser 6 and an outlet diffuser 7 as well as two side walls 8 . In order to reduce the thermal load on the housing 2 and at the same time achieve flexible, independent cooling, the solution of the invention uses a second cooling circuit 10 to cool at least partial regions of the housing 2 , especially the side walls 8 . The second cooling circuit 10 is independent of the first cooling circuit 11 . The inner shell 4 and the outer shell 2 can together form the pipes 9 for the second cooling circuit 10 or the outer shell 2 can be double-walled at least partially (see Figure 4 ), whereby the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com