Blast furnace slag recycling method

A technology for blast furnace slag and charge, which is applied in the field of blast furnace slag iron recycling, can solve the problems of serious environmental pollution, low resource utilization rate, unsuitable for industrial promotion and application, etc., and achieves the effect of blast furnace utilization coefficient and improving drum strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

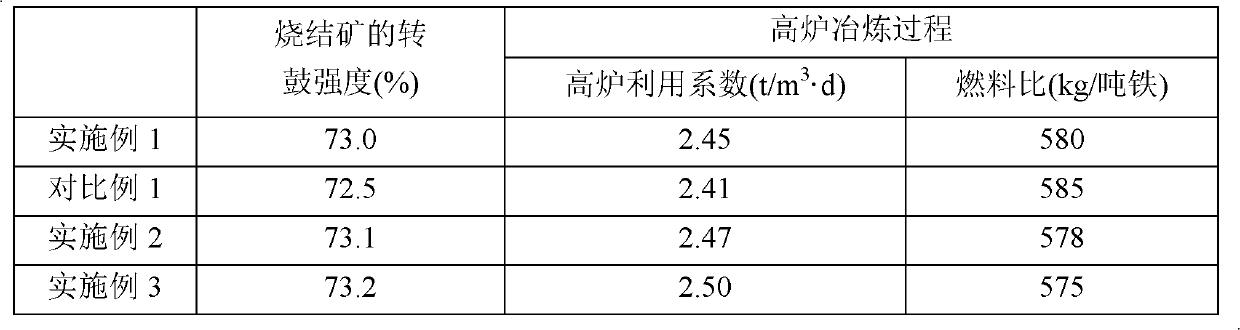

Examples

Embodiment 1

[0035] This embodiment is used to illustrate the method for recycling blast furnace iron slag of the present invention.

[0036] Use a 2-ton heavy hammer to crush blast furnace slag iron (with a particle size of 1000-5000 mm) with an iron content of 20% by weight to less than 100 mm, and then sieve it with a 20 mm vibrating screen to obtain powder with a particle size of less than 20 mm and blocks with a particle size greater than 20 mm.

[0037] The powder is added to a ball mill (purchased from Shanghai Minggong Heavy Equipment Co., Ltd., model ) for ball milling for 8 minutes, and then use a magnetic separator to magnetically separate the milled powder to obtain magnetic powder and non-magnetic powder.

[0038] 52 parts by weight of vanadium-titanium iron ore concentrate, 27 parts by weight of ordinary iron ore concentrate, 52 parts by weight of coke powder, 15 parts by weight of quicklime and 1 part by weight of the magnetic powder are distributed on the magnetic roller ...

Embodiment 2

[0045] This embodiment is used to illustrate the method for recycling blast furnace iron slag of the present invention.

[0046] Use a 5-ton weight hammer to crush blast furnace slag iron (with a particle size of 1000-5000 mm) with an iron content of 40% by weight to less than 100 mm, and then sieve it with a 20 mm vibrating screen to obtain powder with a particle size of less than 20 mm and blocks with a particle size greater than 20 mm.

[0047] The powder is added to a ball mill (purchased from Shanghai Minggong Heavy Equipment Co., Ltd., model ) for 10 minutes, and then use a magnetic separator to magnetically separate the milled powder to obtain magnetic powder and non-magnetic powder.

[0048] 51 parts by weight of vanadium-titanium iron ore concentrate, 27 parts by weight of ordinary iron ore concentrate, 52 parts by weight of coke powder, 15 parts by weight of quicklime and 2 parts by weight of the magnetic powder are distributed on the magnetic roller distributor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com