Star-shaped isoprene-styrene copolymer and preparation method thereof

A kind of technology of isoprene and polyisoprene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

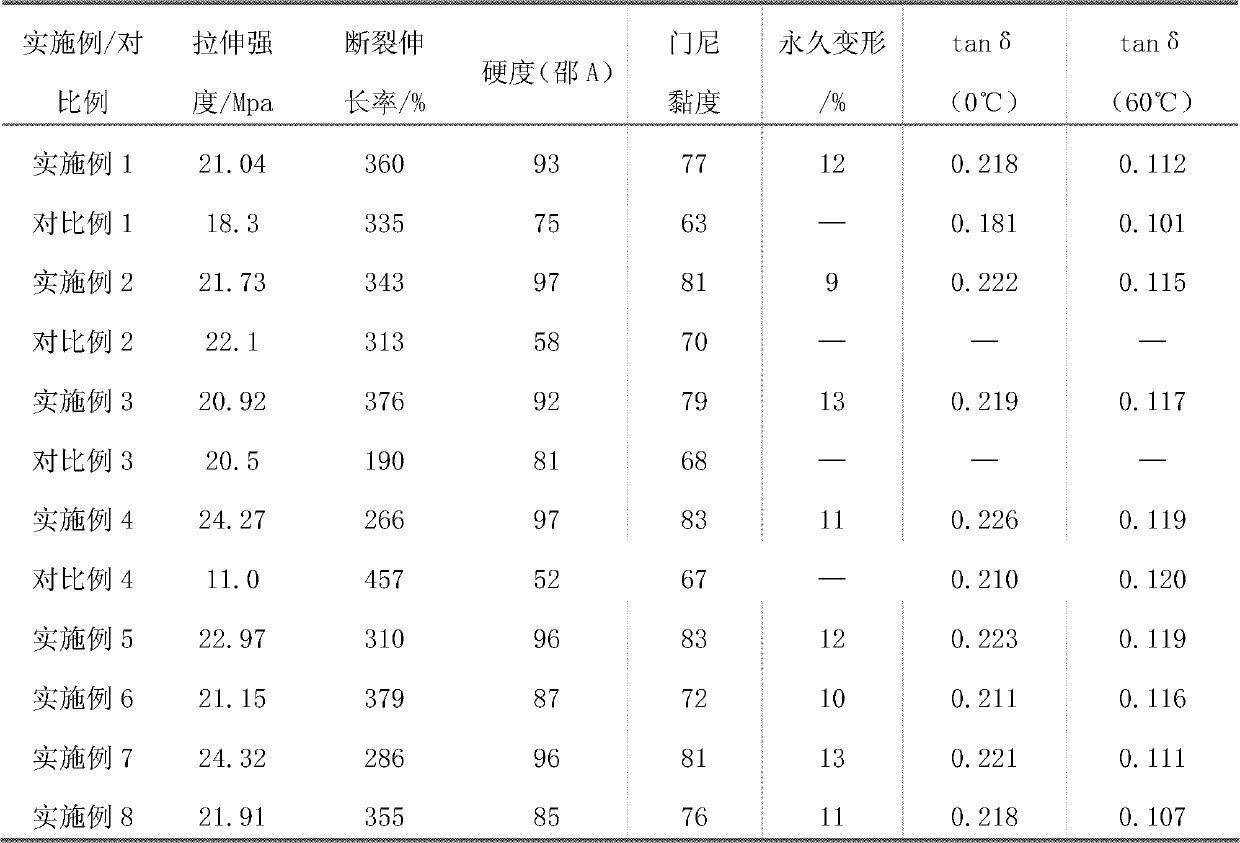

Examples

Embodiment 1

[0029] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 4315g of cyclohexane, 420g of styrene (accounting for 35% of the total amount of monomers), 280g of isoprene (accounting for 23.3% of the total amount of monomers) in the polymerization kettle, add 12.1mmol of n-butyllithium, and heat up to 50°C, polymerize for 80min, and then press the mixture of 4.32g THF, 2194g cyclohexane, 300g styrene (25% of the total monomers), and 200g isoprene (16.7% of the total monomers) Put it into the polymerization tank and continue to react for 60min. After the monomer is completely converted, the temperature is raised to 70°C, and 3.1mmolSnCl is added. 4 The coupling agent is used for coupling reaction, and the reaction time is 60 minutes. After the coupling reaction was completed, the coupled reaction mixture was treated with water, 100 g of water and 12 g of antioxidant 1010 [tetrakis-(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaeryth...

Embodiment 2

[0033] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 4444g of cyclohexane, 330g of styrene (accounting for 27.5% of the total amount of monomers), 300g of isoprene (accounting for 25% of the total amount of monomers) in the polymerization kettle, and accurately add 24.1mmol of n-butyllithium, Raise the temperature to 60°C, polymerize for 50 minutes, and then add a mixture of 8.64g THF, 2088g cyclohexane, 330g styrene (27.5% of the total monomers), and 240g isoprene (20% of the total monomers) Press into the polymerization tank to continue the reaction for 70 minutes. After the monomer is completely converted, the temperature is raised to 80 ° C, and 6.6 mmol SnCl is added in two times. 4 (Joining Sncl for the first time 4 80% of the total amount, after 15 minutes of reaction, add the remaining 20%) coupling agent to carry out the coupling reaction, and the reaction time is 80 minutes. After the coupling reaction was completed,...

Embodiment 3

[0037] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 2044g of cyclohexane in the polymerization kettle, 324g of styrene (accounting for 27% of the total amount of monomers), 396g of isoprene (accounting for 33% of the total amount of monomers), add 8.1mmol of n-butyllithium, and heat up to 60°C, polymerize for 50min, and then press the mixture of 2.16g THF, 3777g cyclohexane, 216g (accounting for 18% of the total amount of monomers) styrene, and 264g (accounting for 22% of the total amount of monomers) of isoprene Put it into the polymerization tank and continue to react for 70min. After the monomer is completely converted, the temperature is raised to 80°C, and 2.2mmolSnCl is added in two times. 4 (Joining Sncl for the first time 4 80% of the total amount, after 15 minutes of reaction, add the remaining 20%) coupling agent to carry out the coupling reaction, and the reaction time is 80 minutes. After the coupling reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com