Optimized coal blending system for pulverized coal gasifier for methanol production

A technology of coal blending system and gasifier, which is applied in the field of pulverized coal gasifier, can solve the problems of reducing the economic benefit of methanol production and preparation, single coal blending optimization management mode, and simultaneous control of coal blending, so as to promote common optimization and improve comprehensive performance and accuracy, and the effect of auxiliary coal blending optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

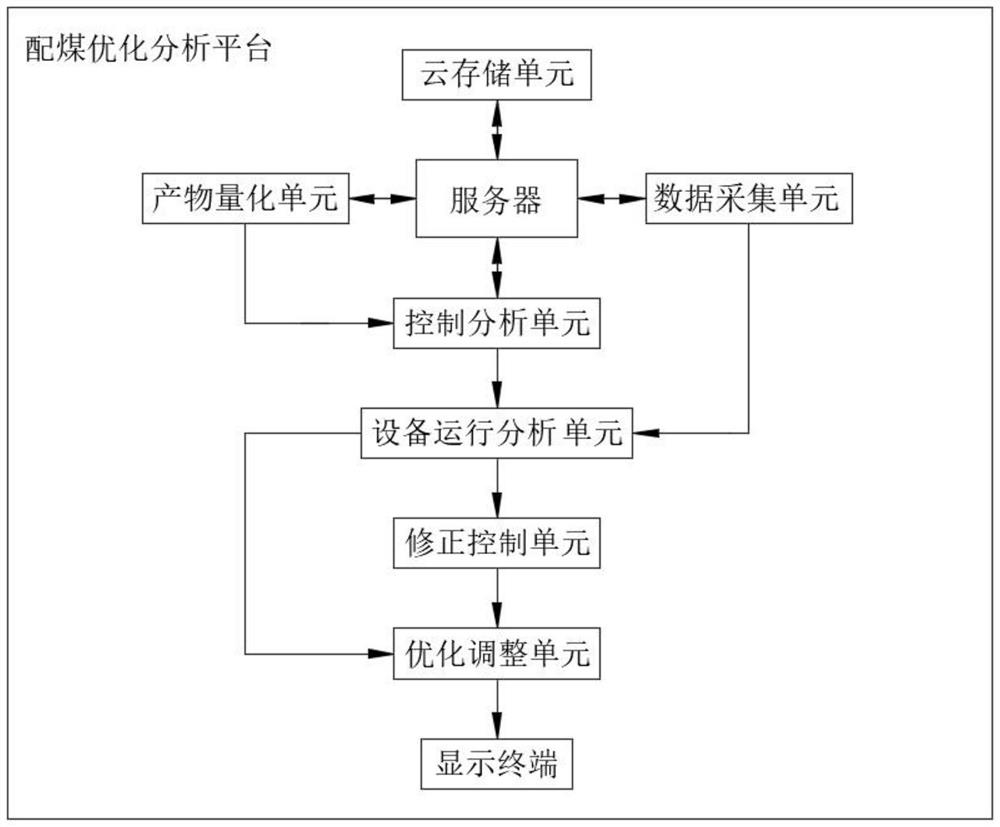

[0047] like figure 1 As shown in the figure, an optimized coal blending system for a pulverized coal gasifier for methanol production includes a coal blending optimization analysis platform. The coal blending optimization analysis platform is internally provided with a server, and the server is connected to a data acquisition unit, a cloud storage unit, a Product quantification unit, control analysis unit, equipment operation analysis unit, correction control unit, optimization adjustment unit and display terminal;

[0048] The coal blending optimization analysis platform is used to maximize methanol production. The server selects the optimal coal blending scheme in the cloud storage unit, and generates an optimization analysis command and sends it to the data acquisition unit. When the data acquisition unit receives the optimization analysis command When the product data information and the working status information of the pulverized coal gasifier are collected, the product ...

Embodiment 2

[0055] like figure 1 As shown, when the data acquisition unit receives the optimization analysis instruction, it collects the product data information of the pulverized coal gasifier accordingly, and sends the product data information to the product quantification unit. When the product quantification unit receives the product data information, and according to This carries out the quantitative analysis and processing of product conversion, and the specific operation steps are as follows:

[0056] Obtain the carbon monoxide value, hydrogen value and methanol value in the product data information per unit time in real time, and calibrate them as yat, qin and jia respectively, according to the formula Zhx=e3×jia÷(e1×yat+e2× qin), obtain the methanol conversion coefficient Zhx, where e1, e2 and e3 are the weighting factor coefficients of carbon monoxide, hydrogen and methanol respectively, and e1+e2+e3=4.7526, it should be noted that the weight The factor coefficient is used to ...

Embodiment 3

[0063] like figure 1 As shown in , when the equipment operation analysis unit receives the gasification condition evaluation instruction, it retrieves the working status information of the pulverized coal gasifier within the same time unit accordingly, and performs operation performance analysis and processing accordingly. The specific operation steps are as follows :

[0064] Obtain the reaction supply temperature value, oxygen temperature value and hole opening value in the working state information of the pulverized coal gasifier in the same unit time in real time, and calibrate them as teg, tog and kol respectively, and normalize them. According to the formula Yux=k1×teg+k2×tog+k3×kol, the operation coefficient Yux of the pulverized coal gasifier is obtained, wherein k1, k2 and k3 are the reaction supply temperature and oxygen temperature, respectively. The correction factor coefficient of the value and the opening value, and k1>k3>k2>0, and k1+k2+k3=1.0574, it should be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com