Manufacturing method of multilayered toy

A production method and technology of toys, which are applied in household appliances, other household appliances, household components, etc., can solve problems affecting the realistic feeling of toys, damage to molds and plastic shells, and increased product scrap rates, so as to achieve good protection and quality Good, the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

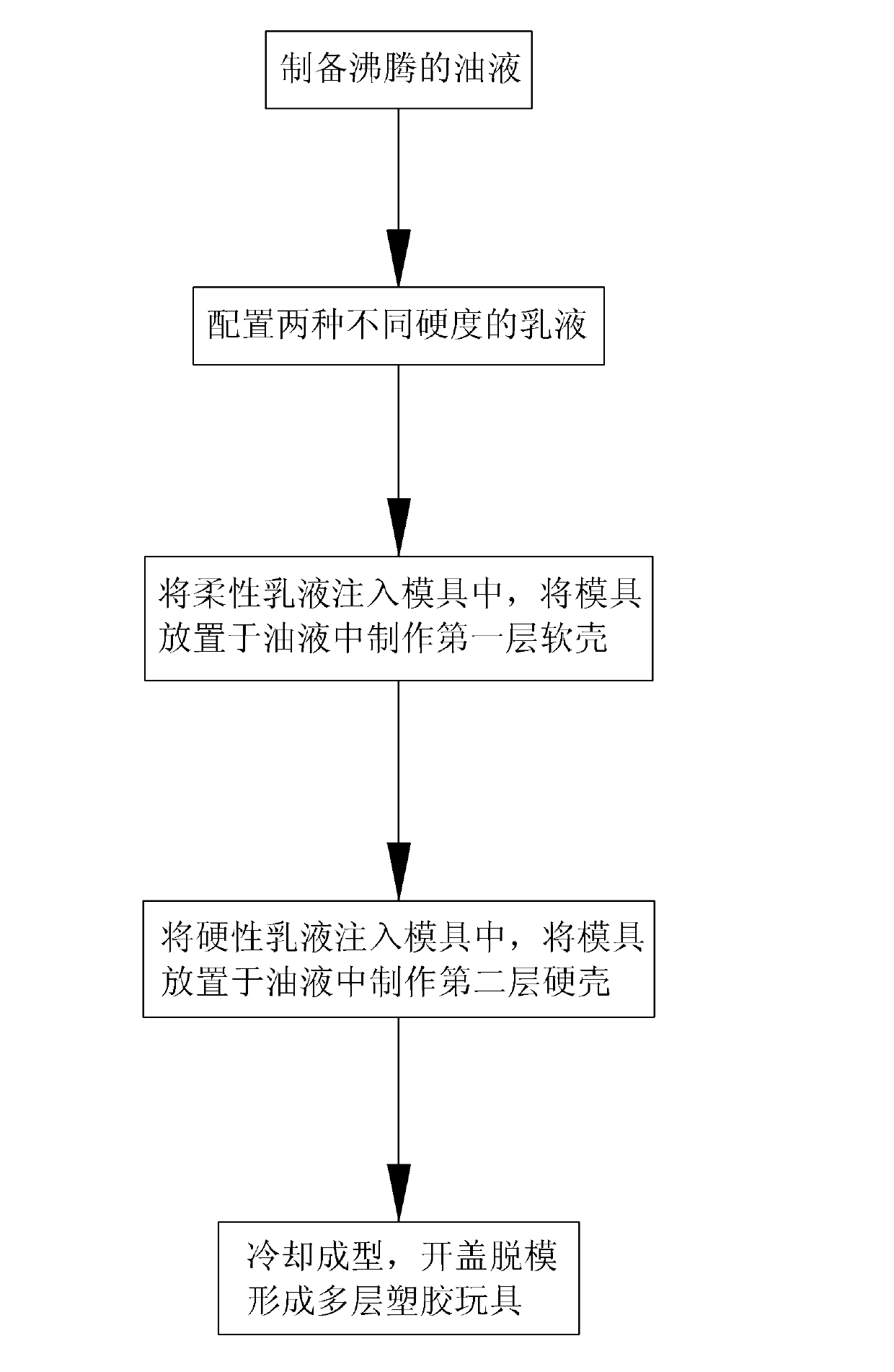

[0027] refer to figure 1 As shown, the present invention discloses a kind of multi-layer toy manufacturing method, utilizes this method to make the plastic toy with soft outside, moderate hardness inside, it comprises the following steps:

[0028] The first step is to prepare a certain amount of boiling oil. The temperature of the oil is 180°C-280°C (this temperature will be adjusted and modified according to the hardness and thickness of the plastic emulsion); specifically, the following methods can be used to prepare the oil Describe the boiling oil: choose a suitable oil furnace, the size of the oil furnace is selected according to the size of the mold and the specific needs, add an appropriate amount of oil in the oil furnace; then heat the oil furnace to make the oil in the oil furnace boil , The temperature of the oil is 180°C-280°C. Boiling oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com