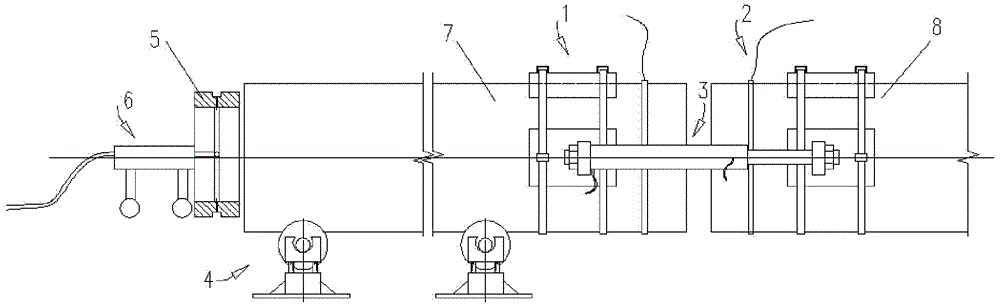

Bimetal composite pipe automatic butt welding equipment

A bimetal composite pipe and welding equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as on-site welding defects, and achieve the effects of improving welding production efficiency, speeding up construction speed, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

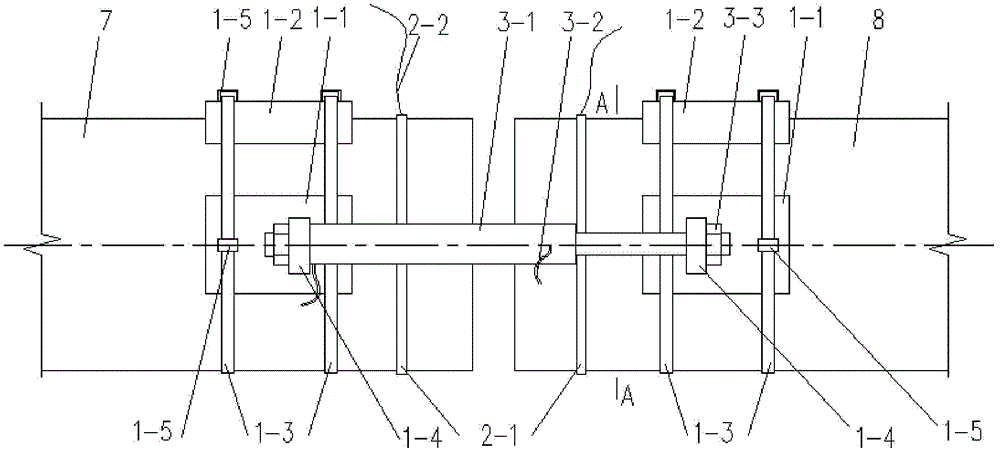

[0048] see Figure 14 , for the bimetallic composite pipe of small size outer diameter, its clamping steps: a. Place the movable bimetallic composite pipe 7 to be welded in the two concave rollers 4-6 of the support adjustment device 4, and rotate The handle 4-3 rotates the lead screw 4-2 to adjust the height, so that the axis of the movable bimetal composite pipe 7 to be welded is aligned with the axis of the static bimetal composite pipe 8 to be welded; b. At the end, two sets of arc-shaped side clamping plates 1-1 are symmetrically arranged on both sides of the outer diameter of the two tubes to be welded, and a set of arc-shaped upper clamping plates 1-2a are respectively arranged on the two tubes to be welded. Above the outer diameter of the welding end, that is, the movable bimetallic composite pipe 7 to be welded and the stationary bimetallic composite pipe 8 to be welded are equipped with three sets of clamping plates on the outer diameter of the adjacent pipe end, lef...

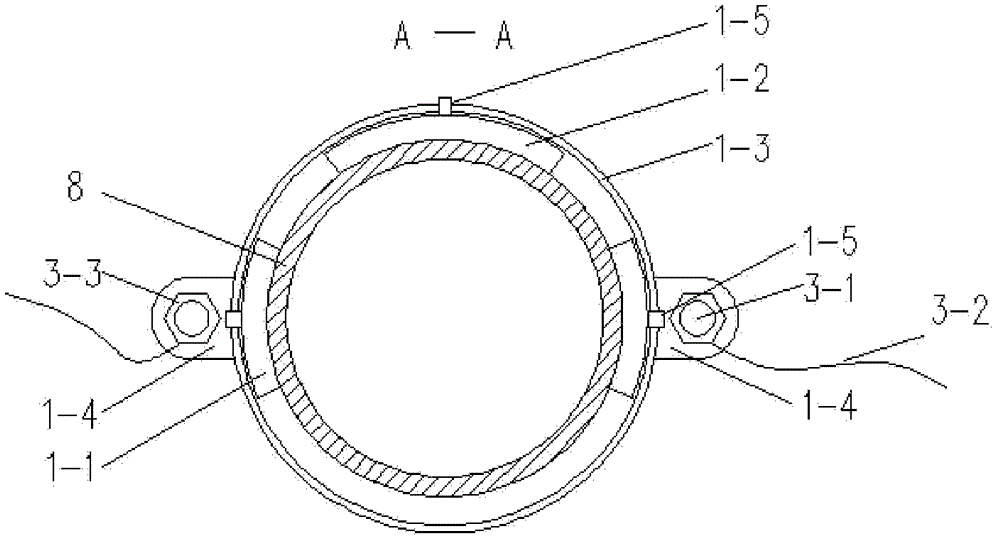

Embodiment 2

[0050] see Figure 15 , for bimetallic composite pipes with large outer diameters, the clamping steps: In order to ensure sufficient welding extrusion force, add a set of lower clamping plates 1-2b. In step b., the adjacent ends of the two pipes are arranged symmetrically on both sides of the outer diameter of the ends of the two pipes to be welded using two sets of arc-shaped side clamping plates 1-1 respectively, and two sets of arc-shaped side clamping plates are used respectively. The upper clamping plate 1-2a and the lower clamping plate 1-2b are arranged above and below the outer diameters of the ends of the two pipes to be welded, that is, the movable bimetallic composite pipe 7 to be welded and the static bimetallic composite pipe to be welded 8 The outer diameters of adjacent pipe ends are equipped with four sets of clamping plates, left, right, upper and lower, arranged evenly, and then the fastening belts 1-3 pass through the buckles 1-5 on the four sets of clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com