Pt-CeO2 modified glassy carbon electrode and its application

A glassy carbon electrode, pt-ceo2 technology, applied in water/sewage treatment, sterilization/microdynamic water/sewage treatment, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Polish the glassy carbon electrode with gold sand photo paper and 0.05μm alumina powder to make the surface of the glassy carbon electrode appear mirrored;

[0024] 2) The polished glassy carbon electrode is sonicated in nitric acid solution (1:1), acetone, ethanol, and deionized water for 5 minutes to remove contaminants on the electrode surface;

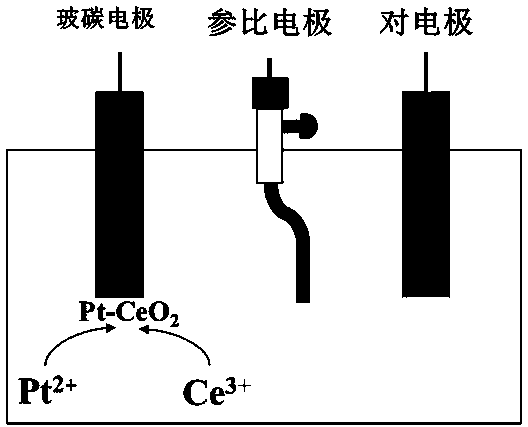

[0025] 3) The pretreated glassy carbon electrode is used as the working electrode, the Pt electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode to form a three-electrode system, and cyclic voltammetric scanning is activated in 0.5mol / L sulfuric acid solution. The scanning range is -1~1V, the scanning speed is 50mv / s, and it stops when the cyclic voltammetry curve is stable;

[0026] 4) Place the three-electrode system at a concentration of 0.5mmol / L H 2 PtCl 6 And 5mmol / L Ce (NO 3 ) 3 In the solution of, carry out cyclic voltammetry scanning in the range of -0.6~0....

Embodiment 2

[0030] 1) Polish the glassy carbon electrode with gold sand photo paper and 0.05μm alumina powder to make the surface of the glassy carbon electrode appear mirrored;

[0031] 2) The polished glassy carbon electrode is placed in nitric acid solution (1:1), in sequence. Ultrasound in acetone, ethanol, and deionized water for 5 minutes to remove contaminants on the electrode surface;

[0032] 3) The pretreated glassy carbon electrode is used as the working electrode, the Pt electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode to form a three-electrode system, and cyclic voltammetric scanning is activated in 0.5mol / L sulfuric acid solution. The scanning range is -1~1V, the scanning speed is 50mv / s, and it stops when the cyclic voltammetry curve is stable;

[0033] 4) Place the three-electrode system at a concentration of 1.0mmol / L H 2 PtCl 6 And 10 mmol / L Ce (NO 3 ) 3 In the solution of, carry out cyclic voltammetry scann...

Embodiment 3

[0037] 1) Polish the glassy carbon electrode with gold sand photo paper and 0.05μm alumina powder to make the surface of the glassy carbon electrode appear mirrored;

[0038] 2) The polished glassy carbon electrode is placed in nitric acid solution (1:1), in sequence. Ultrasound in acetone, ethanol, and deionized water for 5 minutes to remove contaminants on the electrode surface;

[0039] 3) The pretreated glassy carbon electrode is used as the working electrode, the Pt electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode to form a three-electrode system, and cyclic voltammetric scanning is activated in 0.5mol / L sulfuric acid solution. The scanning range is -1~1V, the scanning speed is 50mv / s, and it stops when the cyclic voltammetry curve is stable;

[0040] 4) Put the three-electrode system in the containing 1.5mmol / L H 2 PtCl 6 And 15 mmol / L Ce (NO 3 ) 3 In the solution of, carry out cyclic voltammetry scanning in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com