Adhesive and application thereof as well as adhesive film component and application thereof

A technology of adhesive and adhesive film, which is applied in the field of optical glue, can solve the problem of bubbles on the edge of decorative ink, and achieve the effect of solving bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

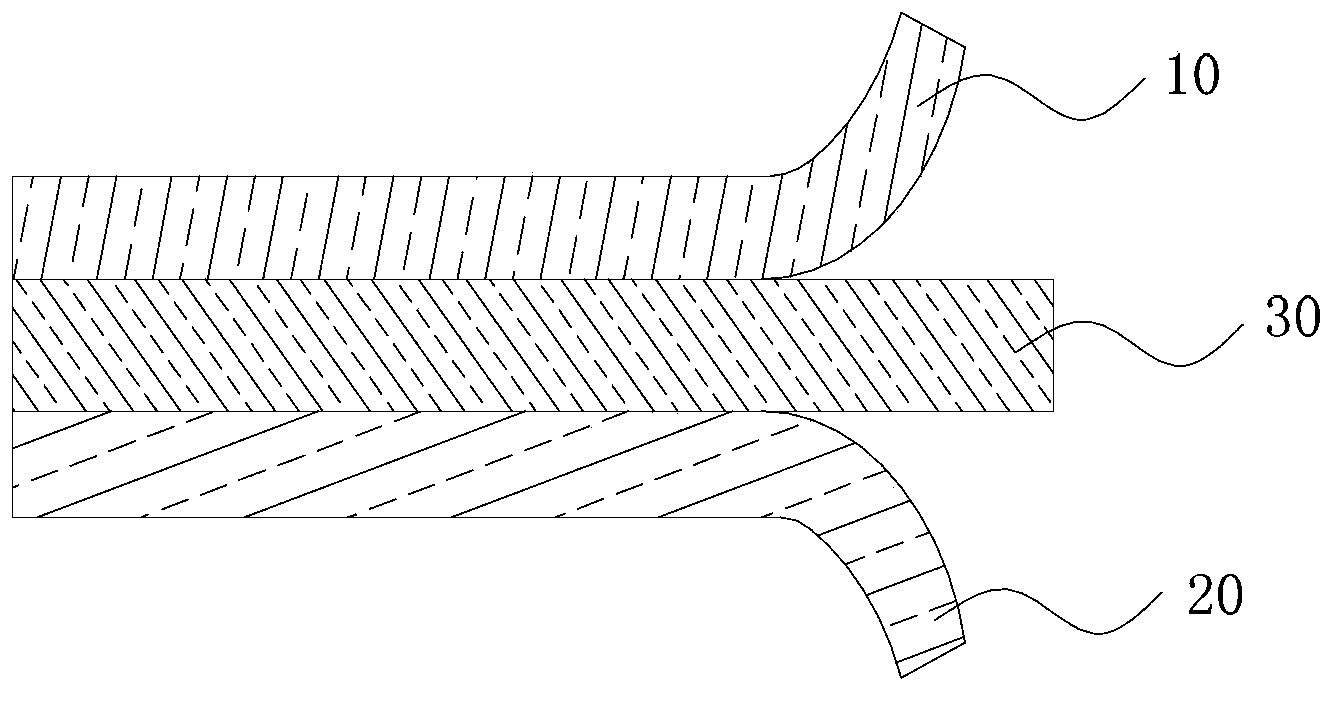

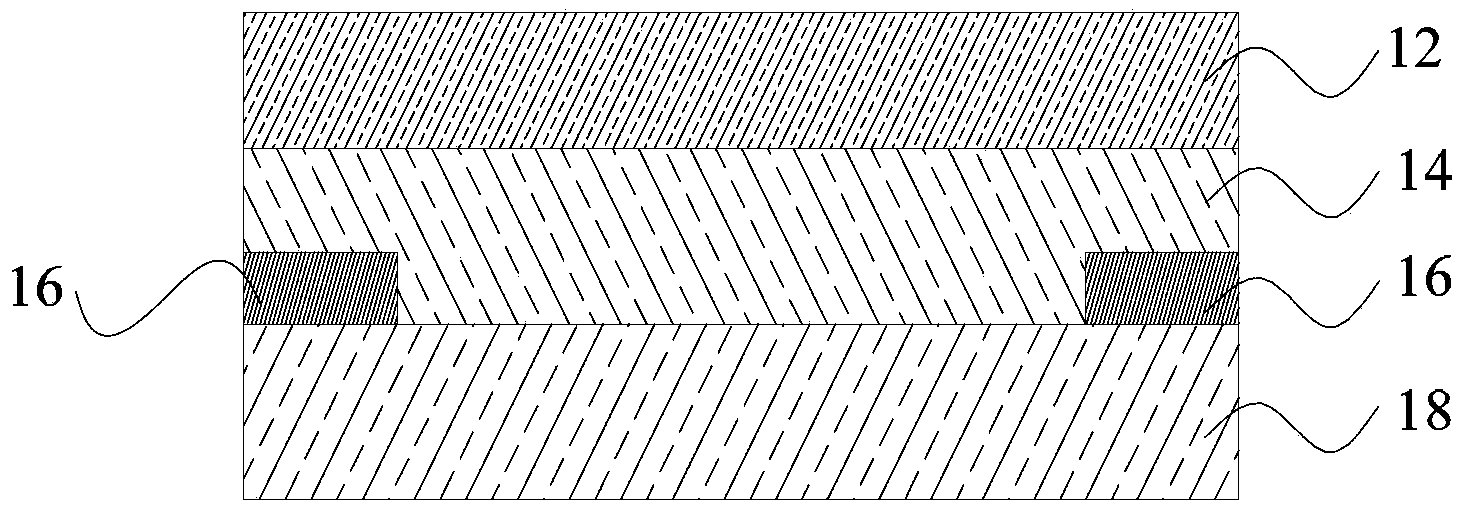

[0074] figure 2 The preparation method of the electronic device shown is as follows: the surface printed with decorative ink 16 on the panel 18 is bonded to the sensor circuit 12 by using an adhesive or an adhesive film assembly, then heated and defoamed, and then hardened by ultraviolet light irradiation.

[0075] The temperature of the heating and defoaming treatment may be 40°C-80°C, the pressure may be 0.4Mpa-0.65Mpa, and the time may be 10min-60min. The purpose of heating defoaming treatment is to use vacuum defoaming technology to remove the air bubbles generated by bonding, and at the same time make the adhesive have a certain fluidity, which can fill the gap between the adherends, thereby removing air bubbles. The wavelength of ultraviolet light irradiated by ultraviolet light can be 200nm~400nm, and the energy can be 500mj / cm 2 ~5000mj / cm 2 . Hardening by ultraviolet light irradiation can harden the adhesive used for laminating the panel 18 and the sensor circuit ...

Embodiment 1

[0078] Add 50 g of polymethyl methacrylate, 29 g of ethyl acrylate and 1 g of quinone diazide into 20 g of tetrahydrofuran solution, and mix well to prepare Adhesive 1. Adhesive 1 is used to bond the panel and the sensor circuit, and the air bubbles in the adhesive 1 are removed under the conditions of 40° C. and a pressure of 0.65 MPa for 40 minutes. Next, use a wavelength of 365nm and an energy of 3000mj / cm 2 The ultraviolet light irradiates the adhesive to harden the adhesive 1. The product obtained after bonding the panel and the sensor circuit with Adhesive 1 has no air bubbles and has a smooth surface.

Embodiment 2

[0080] Add 80g polymethyl methacrylate, 10g ethyl ethacrylate and 3.8g diazonaphthoquinonesulfonyl chloride to 5g cyclohexanone, then add 0.5g p-methoxyphenol, 0.2g diisononyl phthalate Adhesive 2 was prepared after the ester and 0.5 g fatty acid ester were mixed uniformly. After bonding the panel and the sensor circuit with the adhesive 2, degassing treatment was performed at 80°C and a pressure of 0.6Mpa for 10 minutes to remove the air bubbles in the adhesive 2. Next, use a wavelength of 365nm and an energy of 500mj / cm 2 The ultraviolet light irradiates the adhesive to harden the adhesive 2. The product obtained after bonding the panel and the sensor circuit with adhesive 2 has no air bubbles and has a smooth surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com