Halogen-free flame retardant highlight polypropylene and preparation method thereof

A polypropylene and flame retardant technology, which is used in the preparation of halogen-free flame retardant high-gloss polypropylene, can solve the problems of large addition amount, loss of cost advantage of antimony resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The same preparation method can be used for the halogen-free flame-retardant high-gloss polypropylene of the embodiment of the present invention, including the following steps:

[0049] S1. Weigh each component according to the following weight percentages:

[0050] Polypropylene 70-85%;

[0051] Ultrafine barium sulfate 15-25%;

[0052] Halogen-free flame retardant 2~3%;

[0053] Nucleating agent 0.2~0.5%;

[0054] Antioxidant 0.3~0.5%;

[0055] Processing aid 0.5~0.8%.

[0056] S2. Mix all the raw materials weighed evenly;

[0057] S3. Add the mixed raw materials into the parallel twin-screw extruder, melt and extrude, and granulate.

[0058] Among them, the process conditions of the melting stage of the parallel twin-screw extruder in the embodiment of the present invention are: the screw diameter of the parallel twin-screw extruder is 35-75 mm; in the temperature control section of the twin-screw machine, the temperature in the first zone is 180° , the temper...

Embodiment 1

[0060] (1) Weigh 82kg homopolymer PP, 15kg superfine barium sulfate, 2kg halogen-free flame retardant, 0.2kg nucleating agent, 10100.1kg, 1680.2kg antioxidant, 0.2kg lubricant EBS, 0.3KG polypropylene wax;

[0061] (2) Mix all the raw materials weighed in a high-speed mixer for 10 minutes;

[0062](3) Put the uniformly mixed material into the hopper of the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, water-cool, air-dry, pelletize, and finally pack into a finished product. Wherein, the screw speed is 250r / min.

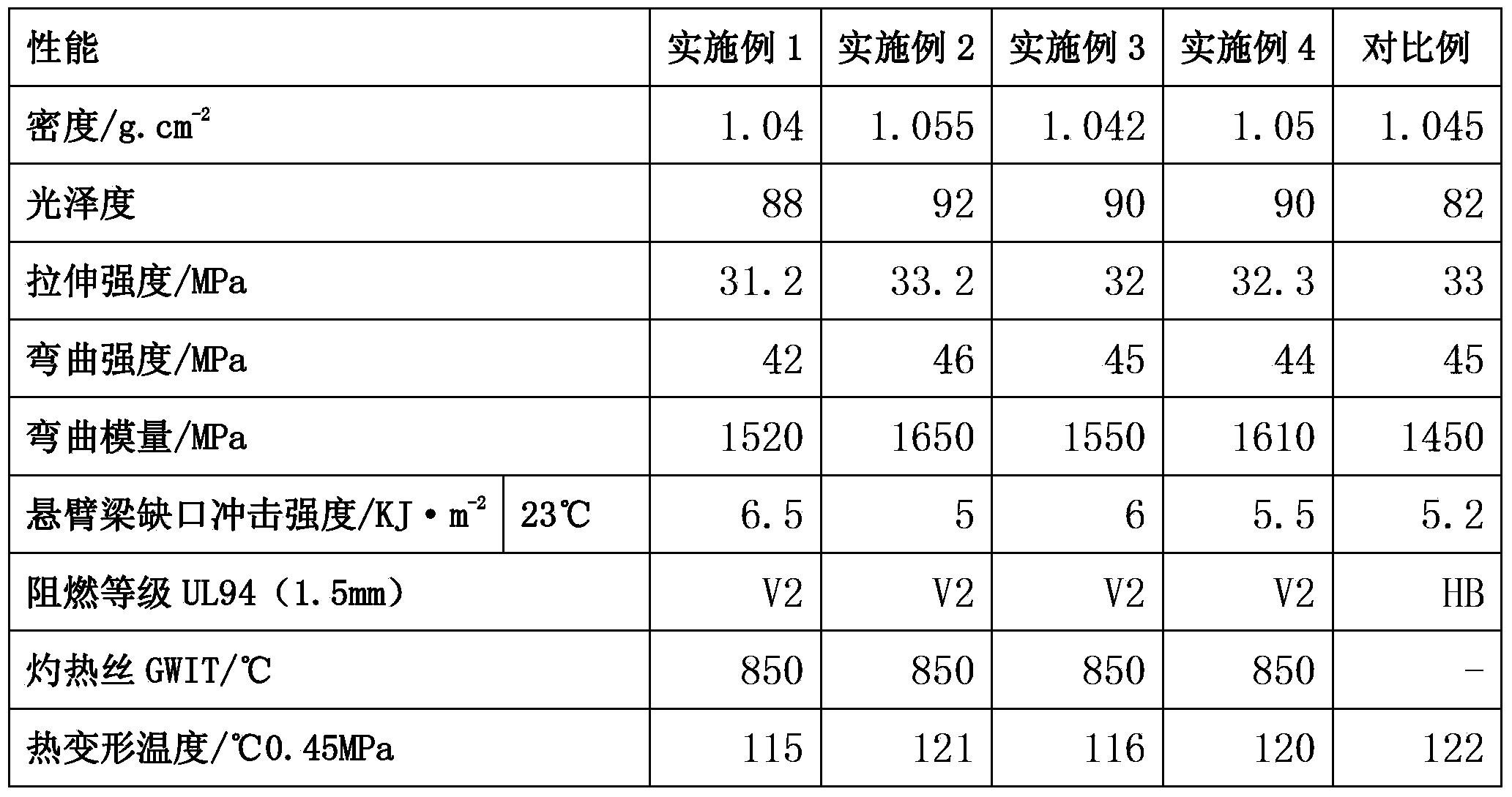

[0063] The above-mentioned halogen-free flame-retardant high-gloss PP was injected into a standard sample, and the test performance is shown in Table 1.

Embodiment 2

[0065] (1) Weigh 70.2kg of homopolymer PP, 25kg of superfine barium sulfate, 3kg of halogen-free flame retardant, 0.5kg of nucleating agent, 10100.3kg of antioxidant, 1680.2kg, lubricant EBS0.3kg, polypropylene wax 0.5KG ;

[0066] (2) Mix all the raw materials weighed in a high-speed mixer for 20 minutes;

[0067] (3) Put the uniformly mixed material into the hopper of the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, water-cool, air-dry, pelletize, and finally pack into a finished product. Wherein, the screw speed is 450r / min.

[0068] The above-mentioned halogen-free flame-retardant high-gloss PP was injected into a standard sample, and the test performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com