Catalyst for catalytic combustion of chlorine-containing organic waste gas

A catalytic combustion, organic waste gas technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, combustion methods, etc., can solve the problem of low initial activity, poor resistance to chlorine poisoning, and poor selectivity. Good and other problems, to achieve good treatment effect, low cost, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

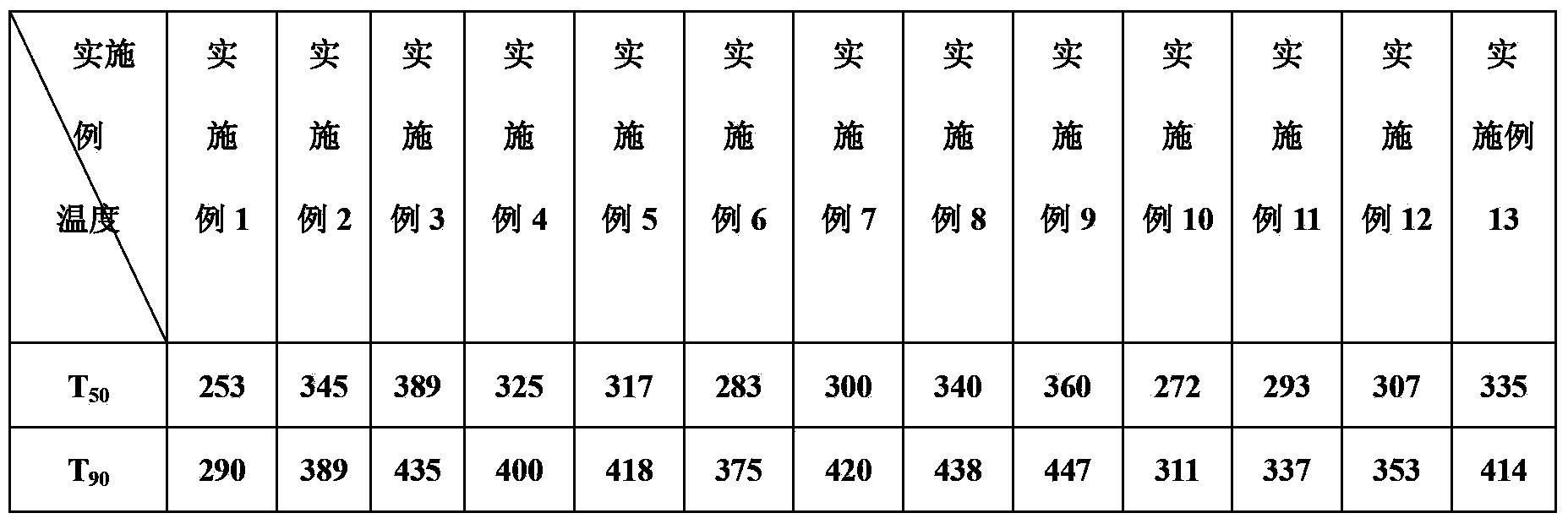

Embodiment 1

[0022] Weigh 0.694 g Ni(NO 3 ) 2 ·6H 2 O, 0.138 g NH 4 VO 3 , Add 100ml deionized water to make a solution. Then, 0.222 g of oxalic acid was added to the solution, and magnetically stirred at 60° C. for 20-30 min until the solute was completely dissolved to obtain an active component impregnation solution.

[0023] Weigh 2 grams of TiO 2 Powder carrier, immerse it in the active component impregnation solution, then transfer all the impregnation solution and carrier to the Erlenmeyer flask, evaporate the solution to dryness at 70°C, dry at 110°C for 12 hours, and bake at 500°C In 5 hours, Ni with a metal element loading of 10% can be prepared 0.7 -V 0.3 / TiO 2 catalyst.

Embodiment 2

[0025] Weigh 0.694 g Ni(NO 3 ) 2 ·6H 2 O, 0.138 g NH 4 VO 3 , Add 100ml deionized water to make a solution. Then, 0.222 g of oxalic acid was added to the solution, and magnetically stirred at 60° C. for 20-30 min until the solute was completely dissolved to obtain an active component impregnation solution.

[0026] Weigh out 2 grams of Al 2 o 3 Powder carrier, immerse it in the active component impregnation solution, then transfer all the impregnation solution and carrier to the Erlenmeyer flask, evaporate the solution to dryness at 70°C, dry at 110°C for 12 hours, and bake at 500°C In 5 hours, Ni with a metal element loading of 10% can be prepared 0.7 -V 0.3 / Al 2 o 3 catalyst.

Embodiment 3

[0028] Weigh 0.694 g Ni(NO 3 ) 2 ·6H 2 O, 0.138 g NH 4 VO 3 , Add 100ml deionized water to make a solution. Then, 0.222 g of oxalic acid was added to the solution, and magnetically stirred at 60° C. for 20-30 min until the solute was completely dissolved to obtain an active component impregnation solution.

[0029] Weigh 2 g of ZrO 2 Powder carrier, immerse it in the active component impregnation solution, then transfer all the impregnation solution and carrier to the Erlenmeyer flask, evaporate the solution to dryness at 70°C, dry at 110°C for 12 hours, and bake at 500°C In 5 hours, Ni with a metal element loading of 10% can be prepared 0.7 -V 0.3 / ZrO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com