Aluminum soldering scratch nail used for incinerator water-cooled wall

A water-cooled wall, incinerator technology, applied in the direction of nails, staples, combustion chambers, etc., can solve the problems of difficult welding and fixing, easy peeling, low strength, etc., to improve welding efficiency, improve welding strength, and effectively weld. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

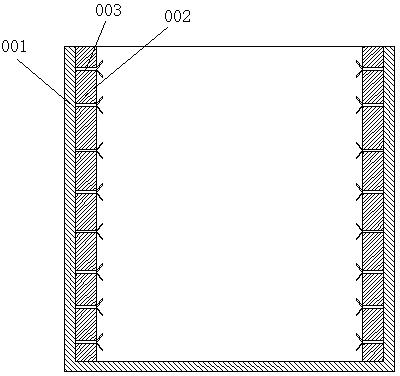

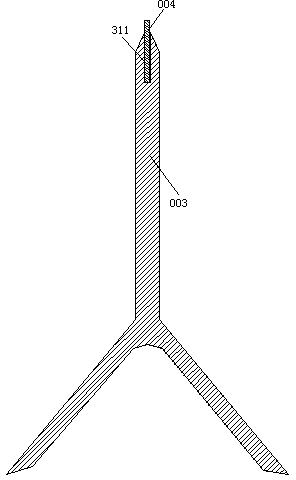

[0010] An aluminum welding nail for an incinerator water wall, comprising an incinerator water wall 001, a wear-resistant plastic protective layer 002 attached to the water wall 001, and an aluminum welding nail 003 fixing the two, the aluminum welding nail One end of the nail 003 is a cylindrical rod body 031, and the other end is a "Y"-shaped fork body 032. The center of the end of the cylindrical rod body 031 is provided with a non-through hole 311, and an aluminum wire 004 is arranged in the non-through hole 311. The aluminum welding nail 003 The end of the cylindrical rod body 031 passes through the wear-resistant plastic protective layer 002 and is welded and fixed to the surface of the water cooling wall 001. The aluminum welding nail 003 is stainless steel.

[0011] For those skilled in the art, under the inspiration of the patent concept and specific embodiments, some deformations that can be directly derived or associated from the patent disclosure and common sense, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com