Damping rubber plate and preparation method thereof

A damping rubber sheet and nitrile rubber technology, applied in the field of damping materials, can solve the problems of small loss factor, environmental pollution of damping rubber sheet, etc., achieve good strength and anti-aging performance, simple production process and use method, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

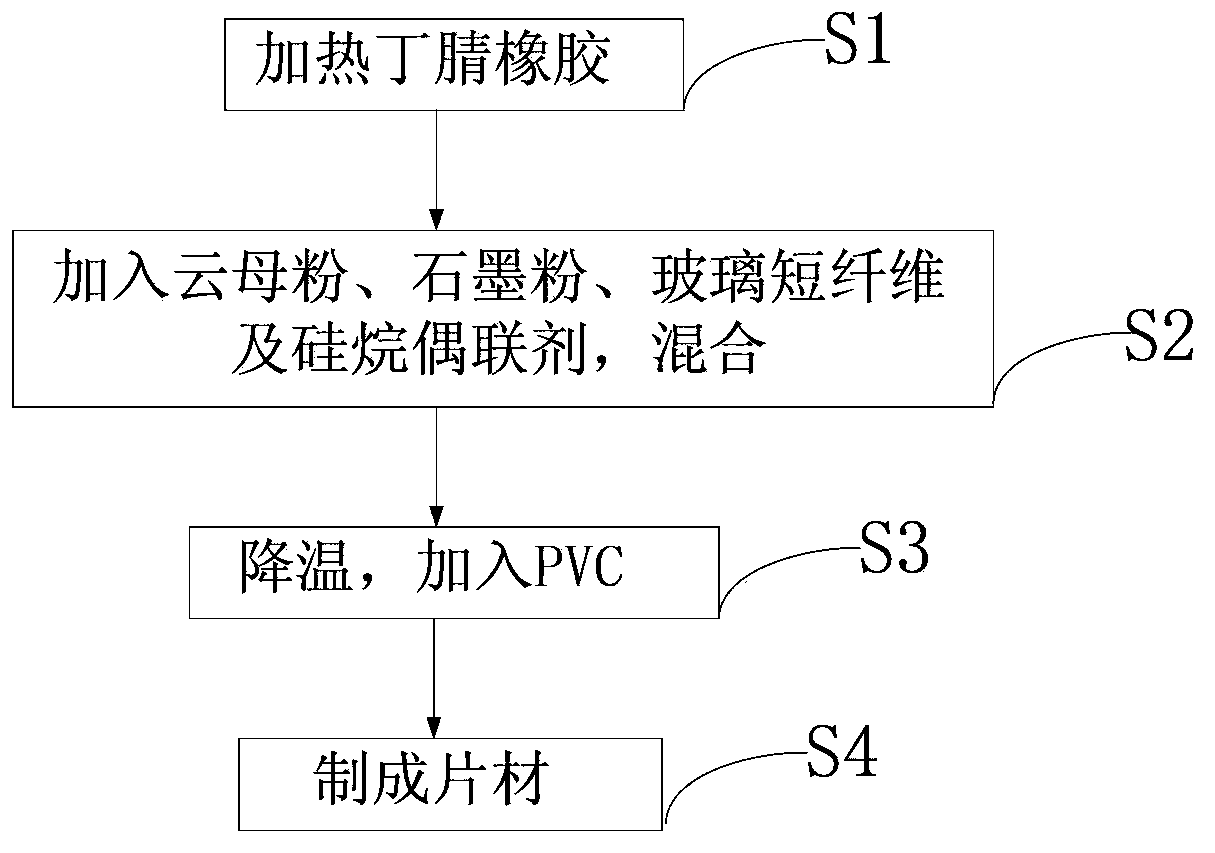

[0039] The preparation method of damping rubber plate comprises the following steps:

[0040] S1: First heat the nitrile rubber to 150℃~180℃, after the nitrile rubber is melted;

[0041] S2: Add mica powder, graphite powder, glass fiber and silane coupling agent, and mix well;

[0042] S3: Lower the temperature to 100-140°C, add powdered PVC, and mix well;

[0043] S4: Extrude the green block with an extruder, and then pass the green block through a double-roller calender to form a sheet with a thickness of 1.5-7.0 mm.

[0044] For the convenience of comparison, the thickness of the damping films in the embodiments of the present invention is 2.0 mm.

Embodiment 1

[0046] Heat 15 parts of nitrile rubber (Nipol) to a molten state, and the melting temperature is 150 ° C ~ 180 ° C, add 20 parts of 120 mesh mica powder, 15 parts of 2000 mesh graphite powder, 10 parts of glass fiber and 3 parts of silane coupling agent 2 -(3,4-epoxycyclohexyl)-ethyltrimethoxysilane, after mixing evenly, lower the temperature to 100°C, then add 15 parts of powdered PVC (3103), mix evenly, and extrude the embryo with an extruder block, and finally the embryo block is made into a sheet with a double-roller calender, and its thickness is 2.0mm.

Embodiment 2

[0048] Heat 25 parts of nitrile rubber (N41) to a molten state, the melting temperature is 150 ° C ~ 180 ° C, add 15 parts of 400 mesh mica powder, 5 parts of 800 mesh graphite powder, 5 parts of glass fiber and 1 part of silane coupling agent 3 - Aminopropyltrimethoxysilane, after mixing evenly, lower the temperature to 120°C, then add 10 parts of powdered PVC (3103), mix evenly, extrude the green block with an extruder, and finally roll the green block with double rollers Machined into sheets, the thickness of which was 2.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com