Method for forming semiconductor device and method for forming MIM capacitor

A semiconductor and capacitor technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as poor reliability of MIM capacitors, and achieve good reliability, uniform thickness, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

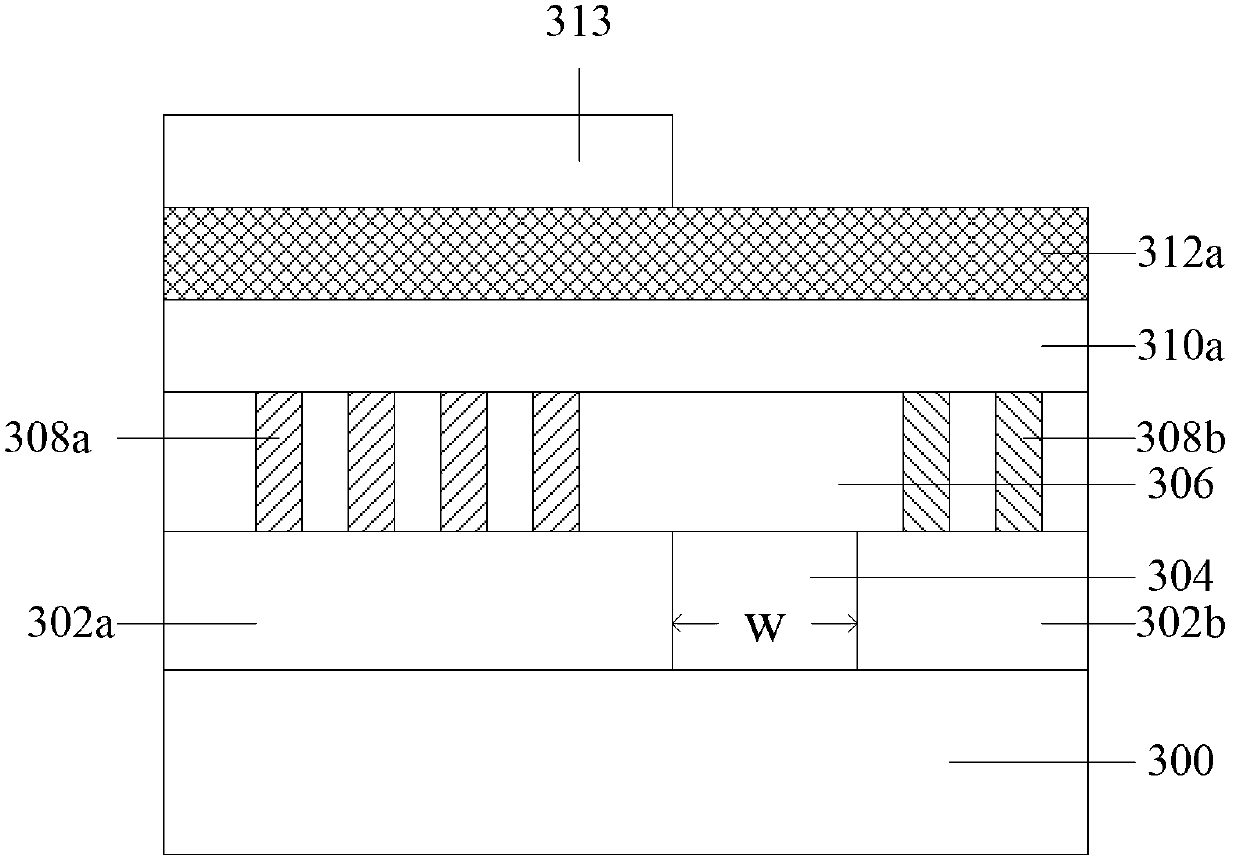

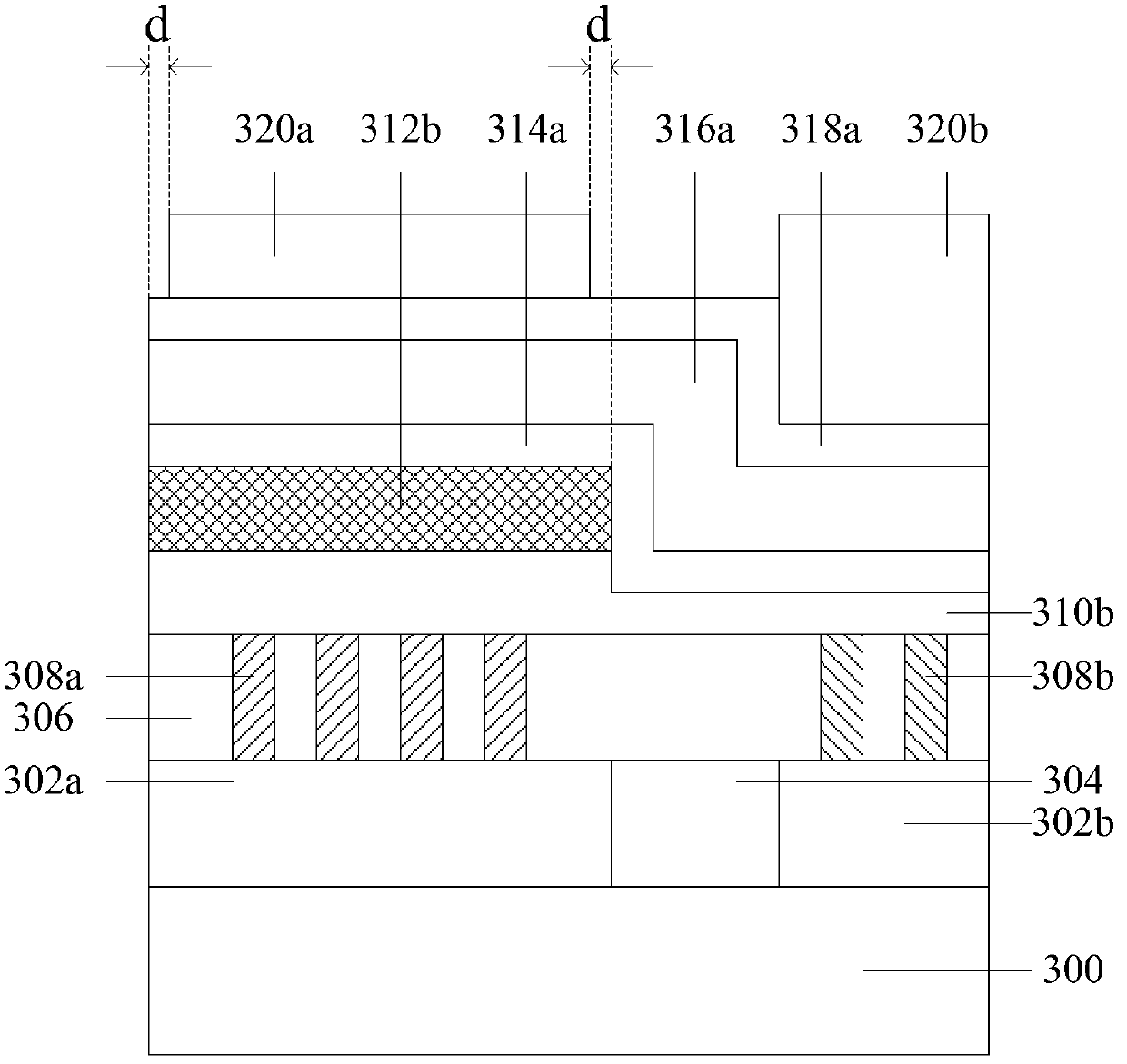

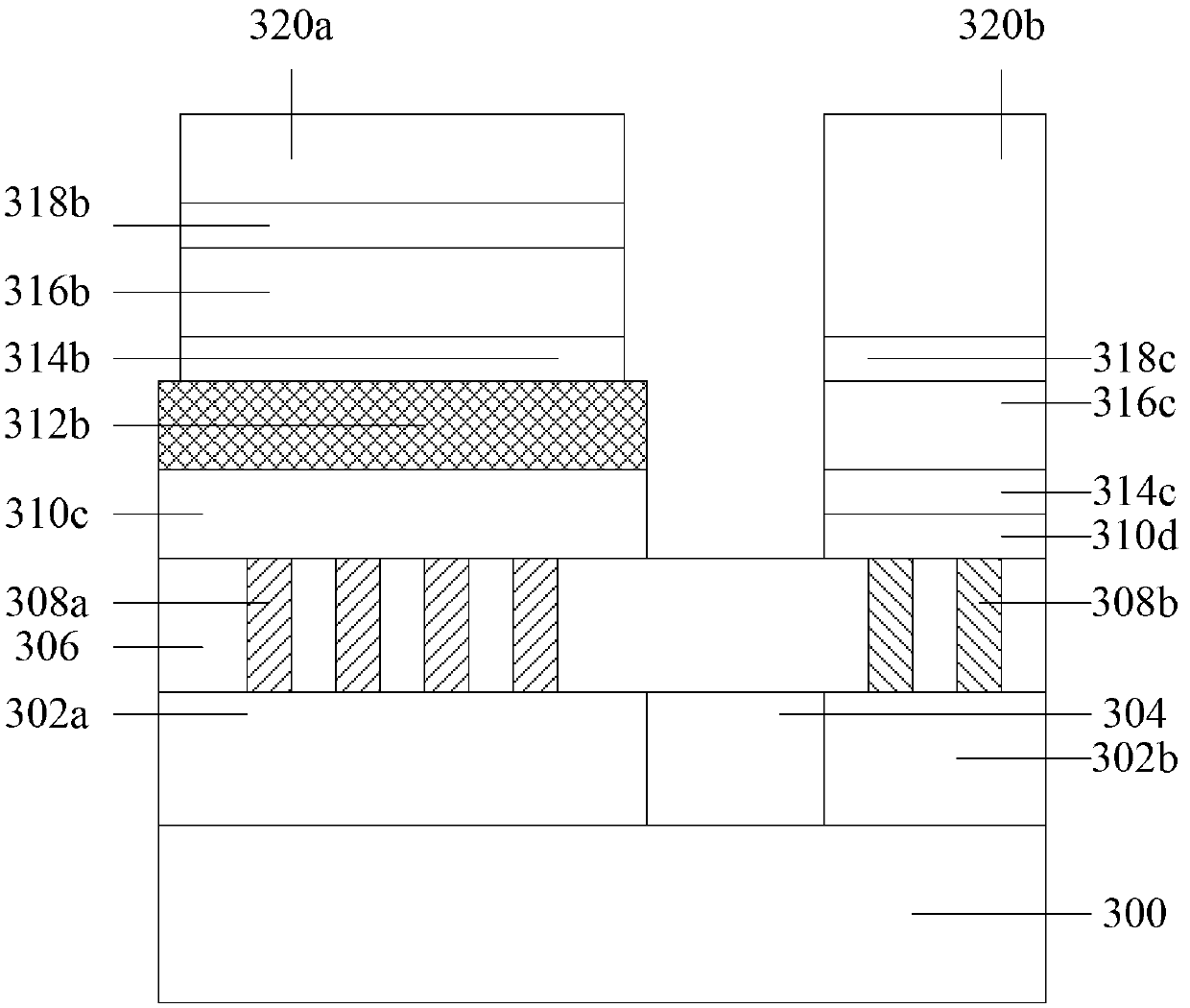

[0036] As mentioned in the background section, MIM capacitors formed by existing processes have poor reliability.

[0037] The reason for the poor reliability of existing MIM capacitors is that aluminum is a metal crystal, and the size of its crystal grains is uneven. The surface is uneven, which leads to the uneven lower surface of the subsequently formed capacitor dielectric layer; silicon oxide and silicon nitride are amorphous, and are formed on the capacitor dielectric layer made of silicon oxide or silicon nitride on the aluminum metal layer The surface is flat, and the upper and lower surfaces of the titanium nitride layer are flat, so the thickness of the capacitor dielectric layer located between the aluminum metal layer and the titanium nitride layer is not uniform. Since the breakdown voltage of the MIM capacitor is determined by the thinnest part of the capacitor dielectric layer, the breakdown voltage of the formed MIM capacitor changes greatly, and the MIM capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com