Preparation method of polypyrrole nano fibers

A polypyrrole nanometer and polypyrrole technology, which is applied in the field of preparation of polypyrrole nanofibers, can solve the problems of poor optical and electrical properties of nanofibers, are not suitable for large-scale production, and have poor optical properties, and achieve good stability and excellent performance. Fluorescent properties, the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

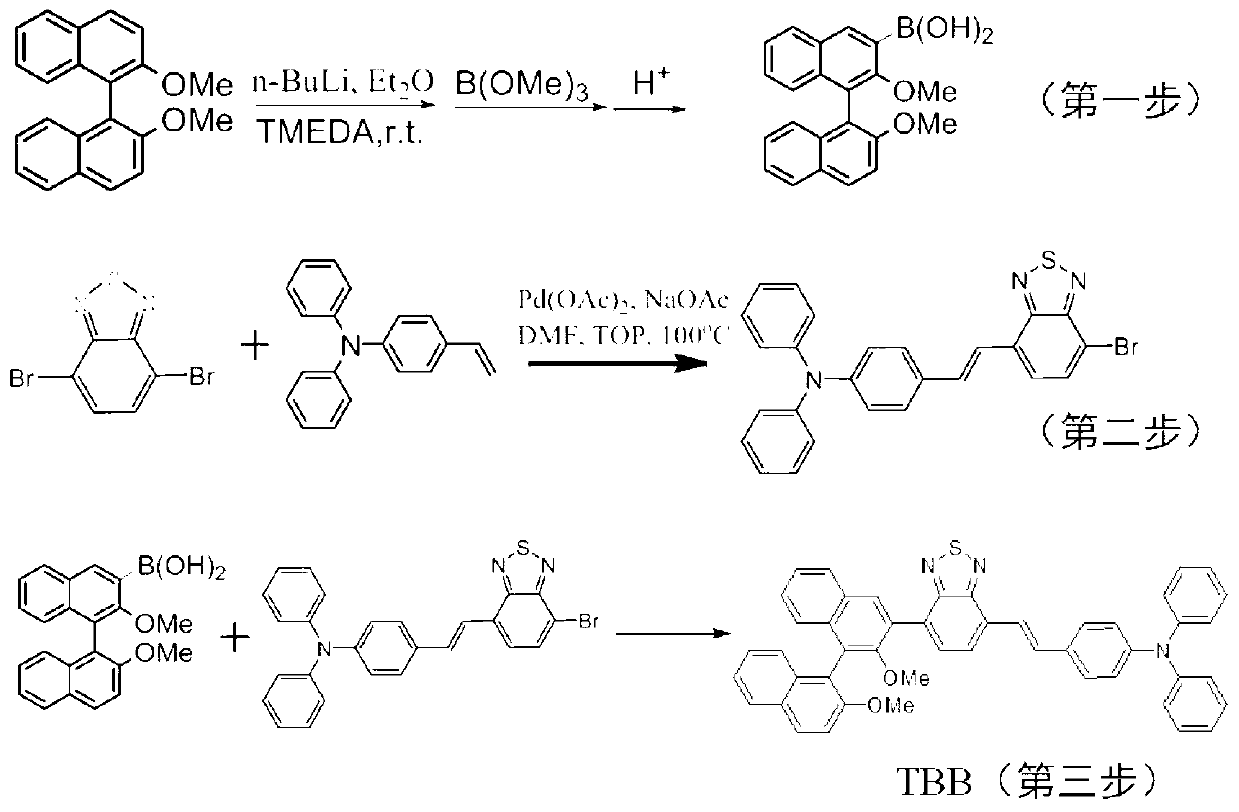

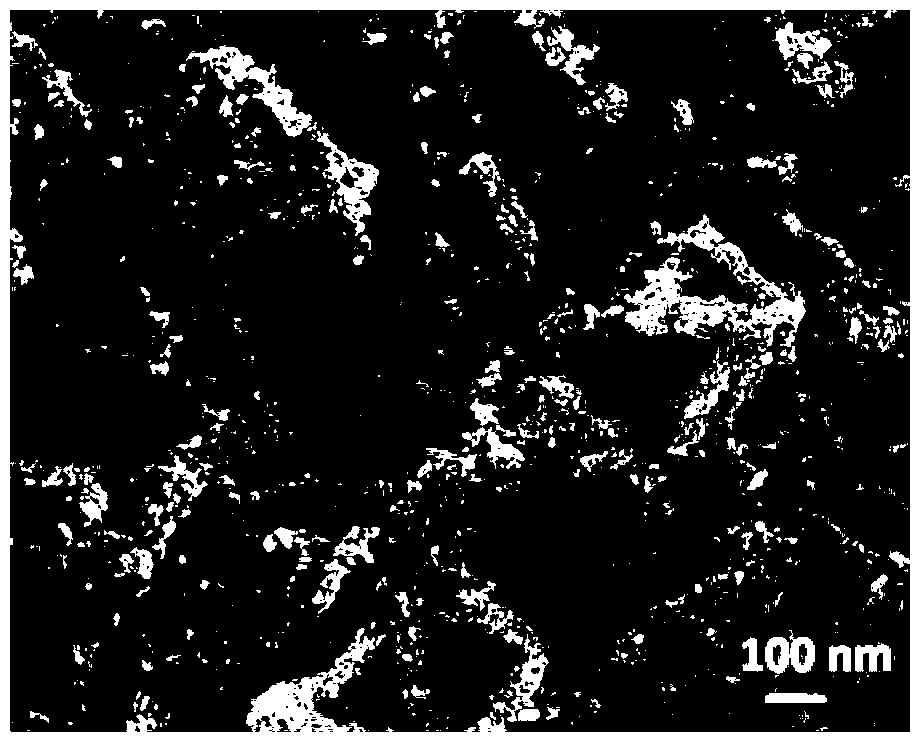

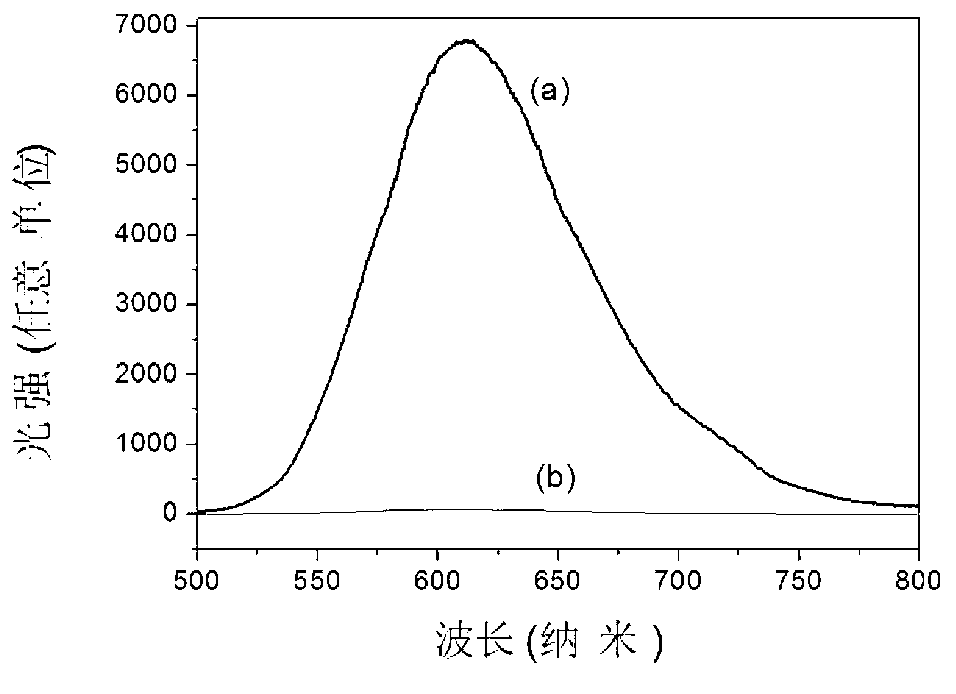

[0019] This example uses benzothiadiazole fluorescent agent 3,3-bis(4-(4,4-diphenylamino)styryl)-{1,2,5-}benzothiadiazolyl )-2,2'-dimethoxy-1,1'-binaphthalene, referred to as TBB as a dopant, doping the benzothiadiazole fluorescent agent TBB onto the polymer main chain, in aqueous solution Polypyrrole nanofibers with both fluorescent and conductive properties are prepared by self-assembly. The specific process is as follows:

[0020] (1) Dispersion of fluorescent agent: Disperse 1-2 grams of benzothiadiazole fluorescent agent TBB in 20 ml of deionized water, and ultrasonically oscillate for 1 hour to obtain a homogeneous solution, that is, aqueous solution of fluorescent agent TBB;

[0021] (2) Distillation and purification of pyrrole monomer: put pyrrole monomer into a conventional vacuum distillation device, heat to 60°C for distillation, and obtain pure pyrrole monomer;

[0022] (3) Fluorescent agent mixed with pyrrole monomer: under the protection of nitrogen, first mix p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com