Method for preparing neodymium and iron oxides by using neodymium iron boron oil sludge through regeneration and co-precipitation

A neodymium-iron-boron and co-precipitation technology, applied in the direction of improving process efficiency, can solve the problems of human injury, acid-base waste liquid is difficult to handle, not made into industrial products, etc., and achieves short operation process and avoids large-scale reagents. Use, the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

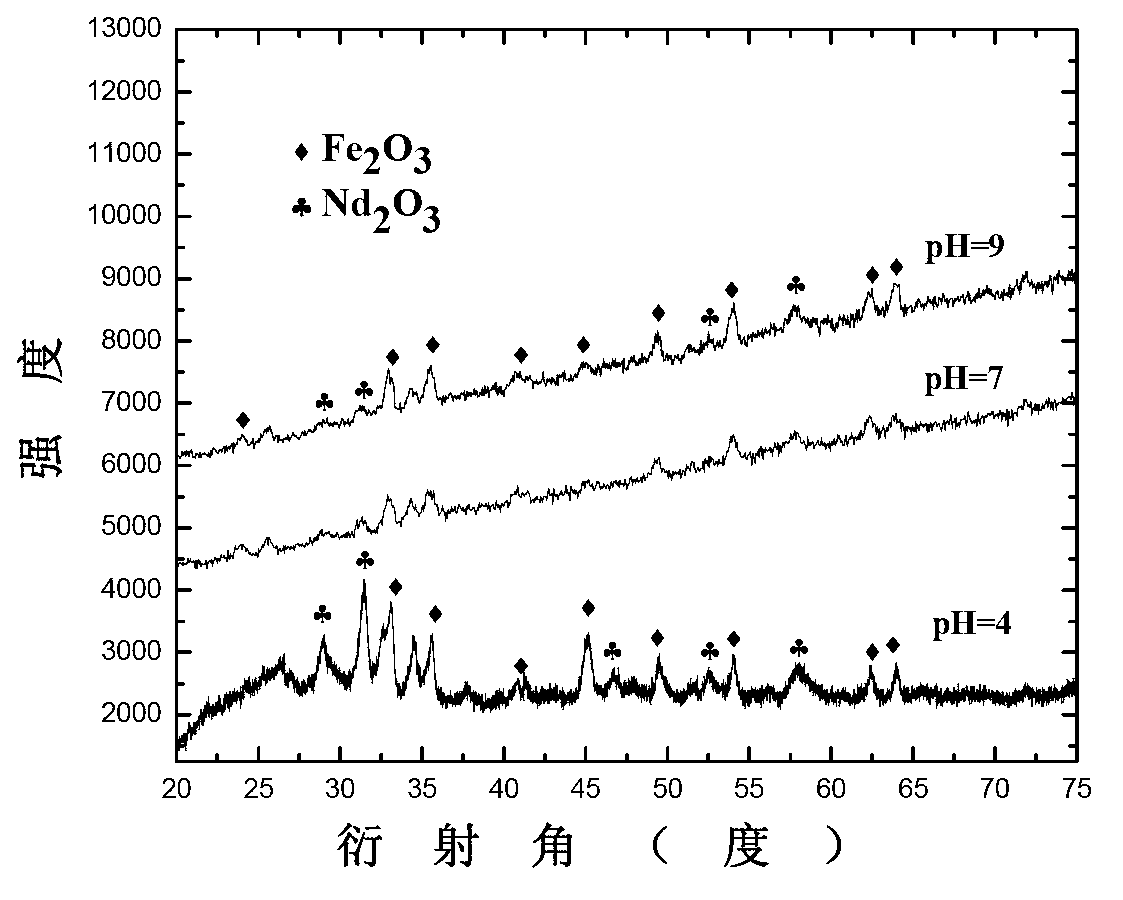

[0024] First, take 5g of NdFeB oil sludge, add 60ml of 4mol / L hydrochloric acid to the waste, and after fully dissolving, add excess hydrogen peroxide to the filtrate and stir for 10min. Then, adjust the pH values to 4, 7, and 9 by adding ammonia water at a volume ratio of 1:1, and place the filtrate in a collector heating stirrer, control the reaction temperature at 70°C, and slowly add 1 mol / L of hydrogen Sodium oxide 30ml and let it react in the mixer for 60mins. Finally, after centrifuging and drying the precipitate, put it in a box furnace, and bake it at T=400°C for 90mins to obtain the mixed oxide of neodymium iron. Through XRD, XRF and other testing methods, we obtained the following results:

[0025] Compare the phase and element content of the Nd-Fe mixed oxide obtained by adding sodium hydroxide and roasting at the pH value of 4, 7, and 9, and analyze and discuss:

[0026]

[0027]

[0028] Table 1-1 XRF results of oxides obtained by roasting at different ...

Embodiment 2

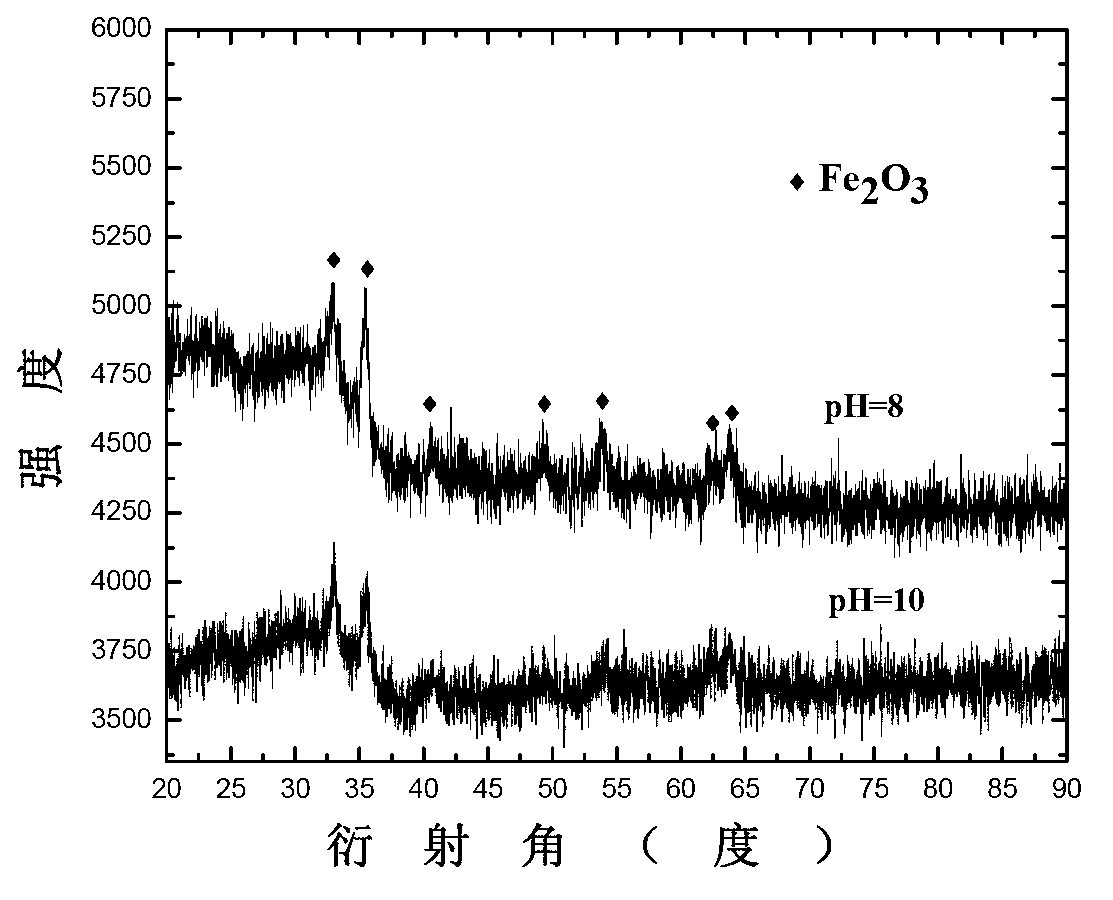

[0031] First, take 5g of NdFeB oil sludge, add 60ml of 4mol / L hydrochloric acid to the waste, and after fully dissolving, add excess hydrogen peroxide to the filtrate and stir for 10min. Then, the filtrate was placed in a collector heating agitator, the reaction temperature was controlled at 70°C, 30% ammonia water was slowly added to adjust the pH value to 5.5, 7.5, and it was allowed to react in the agitator for 60mins. Finally, after centrifuging and drying the precipitate, put it in a box furnace, and bake it at T=400°C for 90mins to obtain the mixed oxide of neodymium iron. Through XRD, XRF and other testing methods, the following results were obtained:

[0032] Compare the phase and element content of the product obtained by adding ammonia water for precipitation and roasting when the pH value is 5.5 and 7.5, and analyze and discuss:

[0033]

[0034]

[0035] Table 1-2 XRF results of products roasted at different pH values when ammonia water is used as precipit...

Embodiment 3

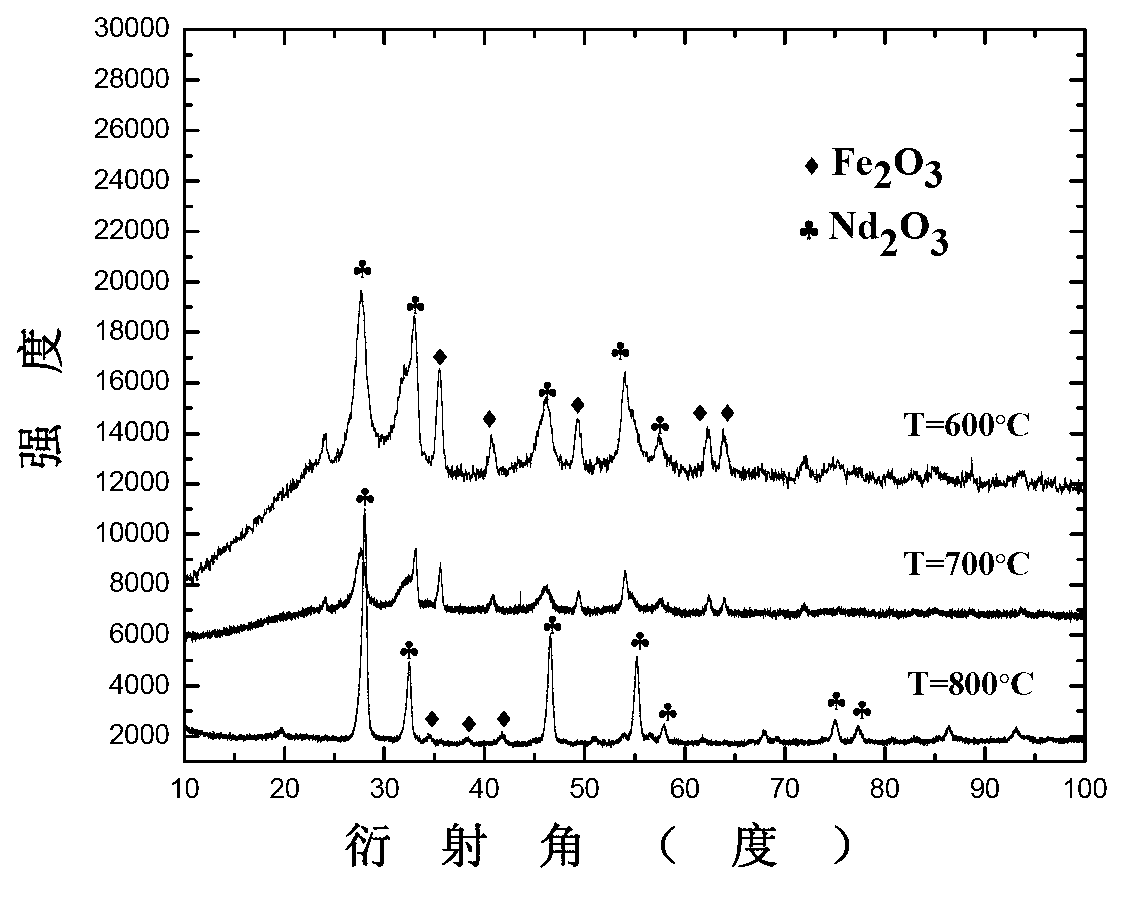

[0038]First, take 5g of NdFeB oil sludge, add 60ml of 4mol / L hydrochloric acid to the waste, and after fully dissolving, add excess hydrogen peroxide to the filtrate and stir for 10min. Then, the pH value was adjusted to be 2 by adding 1:1 ammonia water, and the filtrate was placed in a collector heating stirrer, and the reaction temperature was controlled to be 70°C, and 300ml of hot 0.1mol / L sodium oxalate solution was slowly added and allowed to It was reacted in the mixer for 60mins. Finally, after centrifuging and drying the precipitate, put it in a box furnace, and bake it at T=800°C for 90mins to obtain the mixed oxide of neodymium and iron. Through XRD, XRF and other testing methods, we obtained the following results:

[0039] Table 1-3 XRF results of Nd-Fe mixed oxide calcined with sodium oxalate as precipitant (%)

[0040]

[0041] Depend on image 3 It can be seen that the peak half-maximum width of the precipitate obtained by burning at 800°C is the smallest,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com