Method for controlling heat crack and residual stress of Fe-based fusion-repair layer via ultrasonic impact

A residual stress and ultrasonic impact technology, applied in the field of welding, can solve the problems of high surface hardness of the cladding layer, difficulty in applying post-weld heat treatment, limitations and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

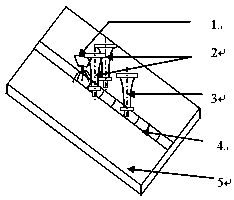

[0021] Ultrasonic impact treatment was performed on the Fe302 self-fluxing alloy powder fused layer with a thickness of 1mm. Include the following steps:

[0022] The first step: the installation of the ultrasonic impact gun for controlling thermal cracking: install two rows of ultrasonic impact guns for controlling thermal cracking at a distance of 35mm from the front welding torch. The ultrasonic impact gun is perpendicular to the surface of the workpiece being processed, and the diameter of the impact head is 3mm. The hardness of the impact needle should be guaranteed not to be lower than 55HRC;

[0023] The second step: the installation of the ultrasonic impact gun to control the residual stress: install an ultrasonic impact gun to control the residual stress at a distance of 100mm from the front welding torch, the ultrasonic impact gun is perpendicular to the surface of the workpiece to be processed, the impact head diameter is 5mm, The hardness of the needle should be g...

Embodiment 2

[0028] Ultrasonic impact treatment was carried out on the Fe302 self-fluxing alloy powder fused layer with a thickness of 0.5 mm. Include the following steps:

[0029] The first step: the installation of the ultrasonic impact gun for controlling thermal cracking: install two rows of ultrasonic impact guns for controlling thermal cracking at a distance of 40 mm from the front welding torch. The ultrasonic impact gun is perpendicular to the surface of the workpiece being processed, and the diameter of the impact head is 3 mm. The hardness of the impact needle should be guaranteed not to be lower than 55HRC;

[0030] Step 2: Installation of an ultrasonic impact gun to control residual stress: Install an ultrasonic impact gun to control residual stress at a distance of 110mm from the front welding torch. The ultrasonic impact gun is perpendicular to the surface of the workpiece to be processed. The hardness of the needle should be guaranteed not to be lower than 55HRC;

[0031] ...

Embodiment 3

[0035] Ultrasonic impact treatment was carried out on the 3mm thick Fe302 self-fluxing alloy powder fused layer. Include the following steps:

[0036] The first step: the installation of the ultrasonic impact gun for controlling thermal cracking: install two rows of ultrasonic impact guns for controlling thermal cracking at a distance of 37mm from the front welding torch. The ultrasonic impact gun is perpendicular to the surface of the workpiece being processed, and the diameter of the impact head is 4mm. The hardness of the impact needle should be guaranteed not to be lower than 55HRC;

[0037] Step 2: Installation of an ultrasonic impact gun to control residual stress: install an ultrasonic impact gun to control residual stress at a distance of 120 mm from the front welding torch, the ultrasonic impact gun is perpendicular to the surface of the workpiece to be processed, the diameter of the impact head is 6 mm, and The hardness of the needle should be guaranteed not to be low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com