Hot-rolled steel and steel part

A component and steel technology, applied in the direction of anti-centrifugal rotating parts, mechanical equipment, shafts and bearings, etc., can solve the problem of increased shape deformation of the sliding part of the connecting rod, inability to apply high-strength connecting rods, low yield specific tensile strength, etc. Improve economic efficiency, reduce plastic deformation, and improve machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

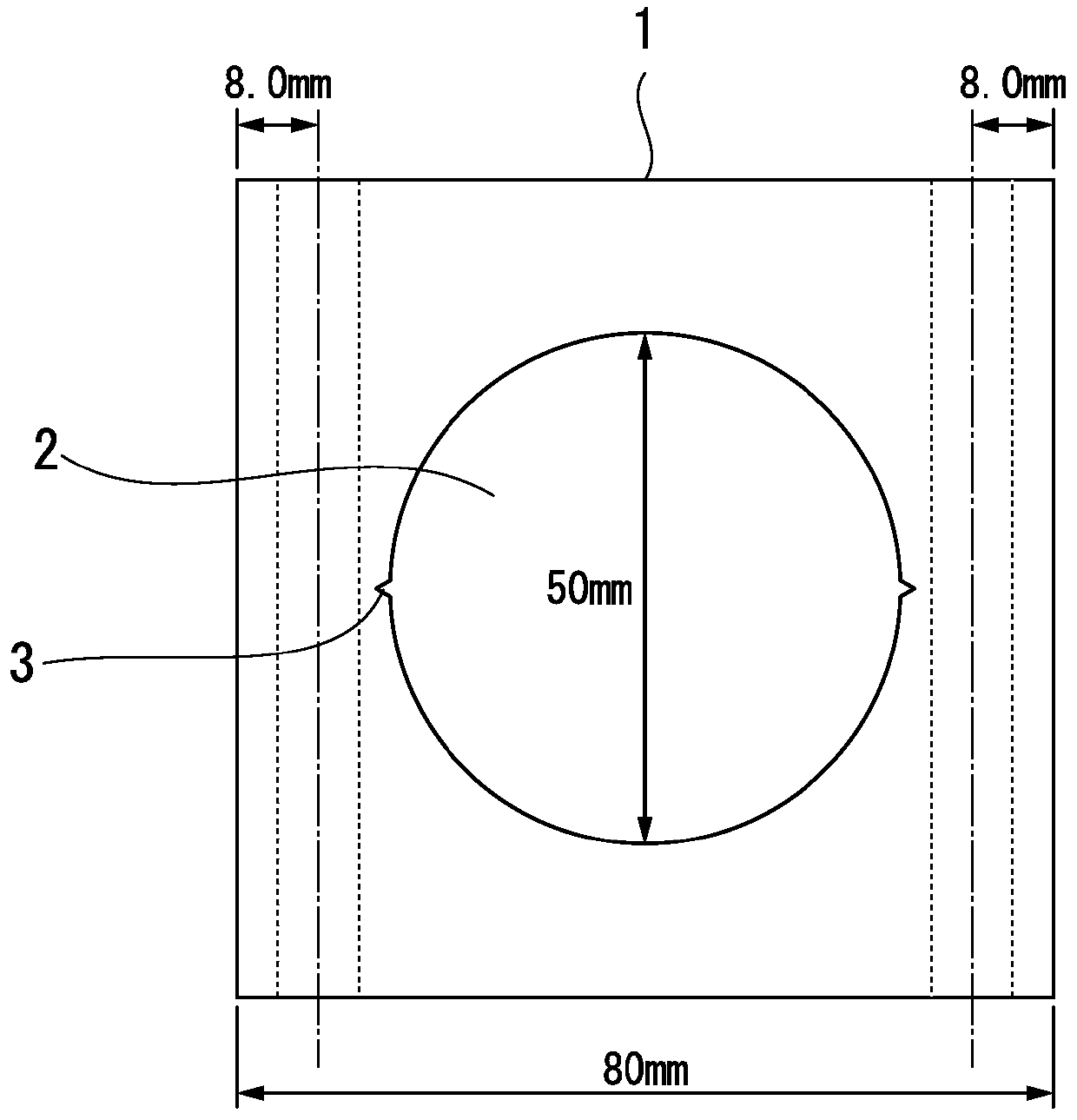

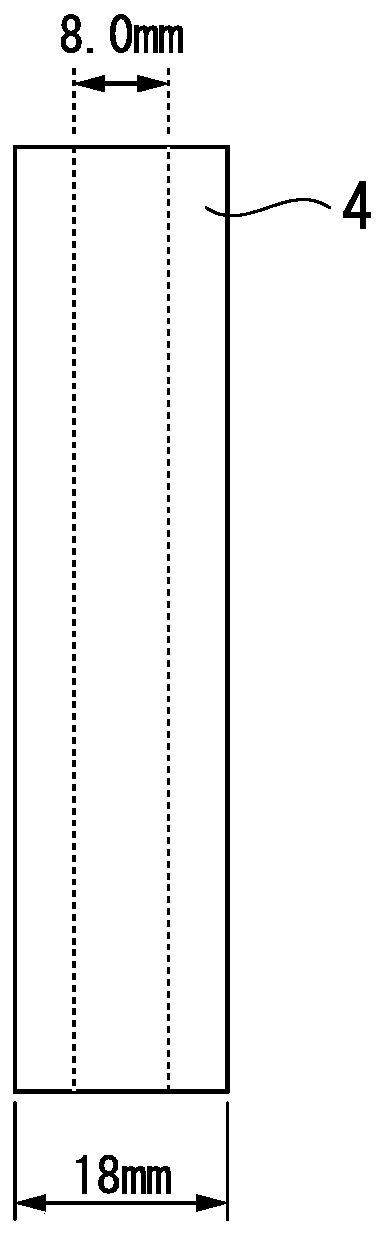

[0112] Converter smelted steel having the composition shown in Table 1 and Table 2 was cast by ingot casting process, and then made into a 162 mm square billet through a billet rolling process, and further hot rolled to make a 56 mm diameter billet. steel bar shape. When the billet is hot-rolled into a round bar shape, the total reduction of area is set to 90%, and the reduction of area in the temperature range of 1000° C. or lower is set to 80%. In addition, the sign of "-" in a table|surface shows that the content of the element related to the place where a sign is described is below a detection limit (impurity level). The heating temperature and heating time of the steel ingot before billet rolling were 1270°C and 140 minutes, respectively, and the heating temperature and heating time of the steel billet before hot rolling were 1240°C and 90 minutes, respectively. The underlined values in Table 2 are within the range of the present invention.

[0113] Mn contained in th...

Embodiment 2

[0153] Steel No.H-2 and Steel No.H-3 having the same chemical composition as Steel No.H recorded in Table 1 were produced under the conditions described in Table 5, and the steels that satisfied the present invention contained in these steels were measured. The average number density of Mn sulfides specified by the equivalent circle diameter and the specified aspect ratio (Mn sulfide number density). The "total reduction of area" in Table 5 is the total reduction of area (%) during hot rolling, and the "reduction of area below 1000°C" is the total reduction of area during the period when the temperature of the steel during hot rolling is 1000°C or lower. Ratio (%), "Mn sulfide number density" is the number density (number / mm 2 ). The production conditions not described in Table 5 were set to be the same as those of Production Nos. 1 to 33.

[0154] [table 5]

[0155]

[0156] As shown in Table 1, the Mn sulfide number density of Steel No. H was within the range of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com