Non-quenched and tempered steel

A non-quenching and tempering, steel technology, applied in the field of blanks for steel parts, can solve the problems of not being able to mesh with good precision, reducing the deformation of the fracture surface, etc., and achieve the effects of excellent fracture separation, less debris generation, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

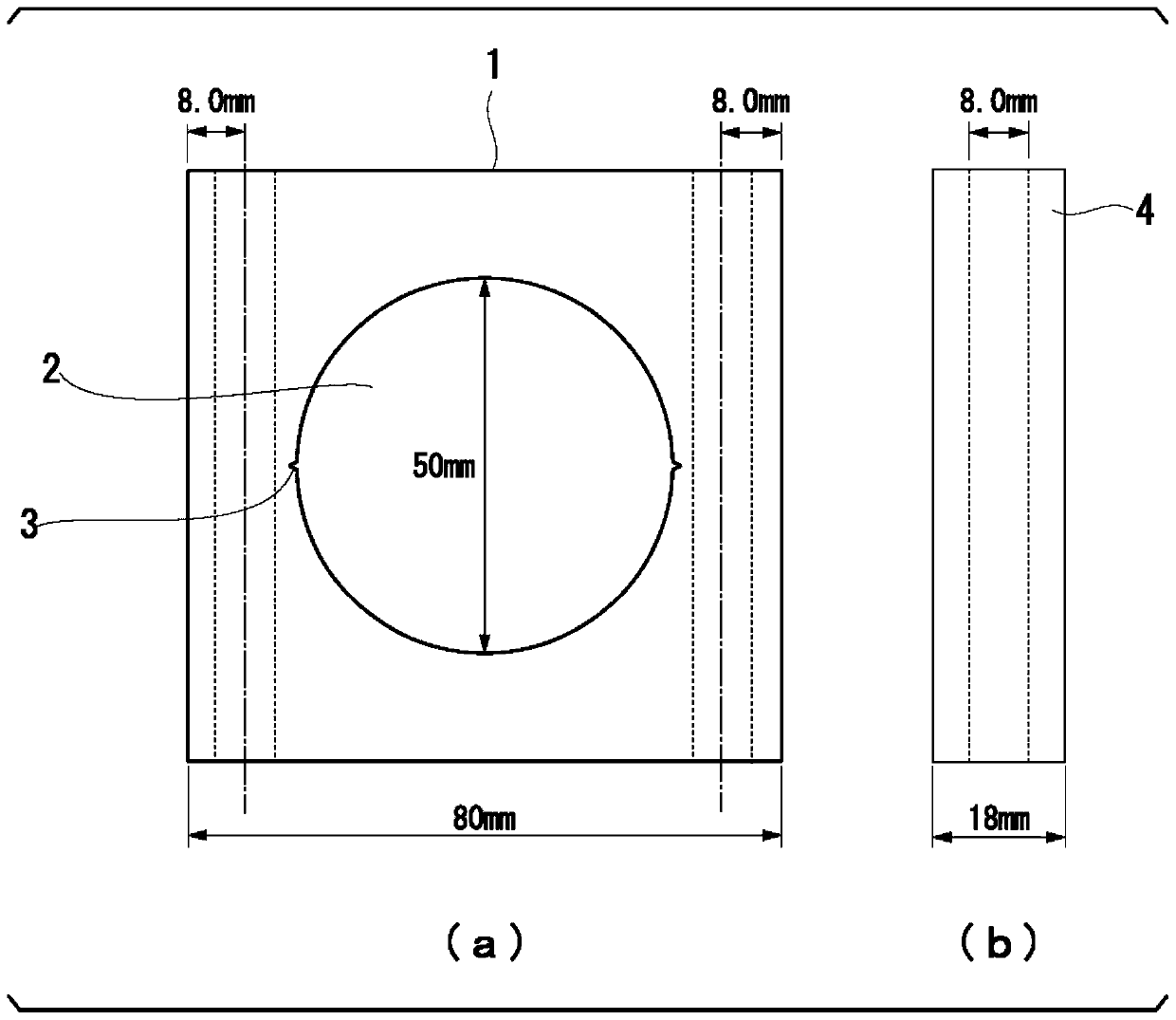

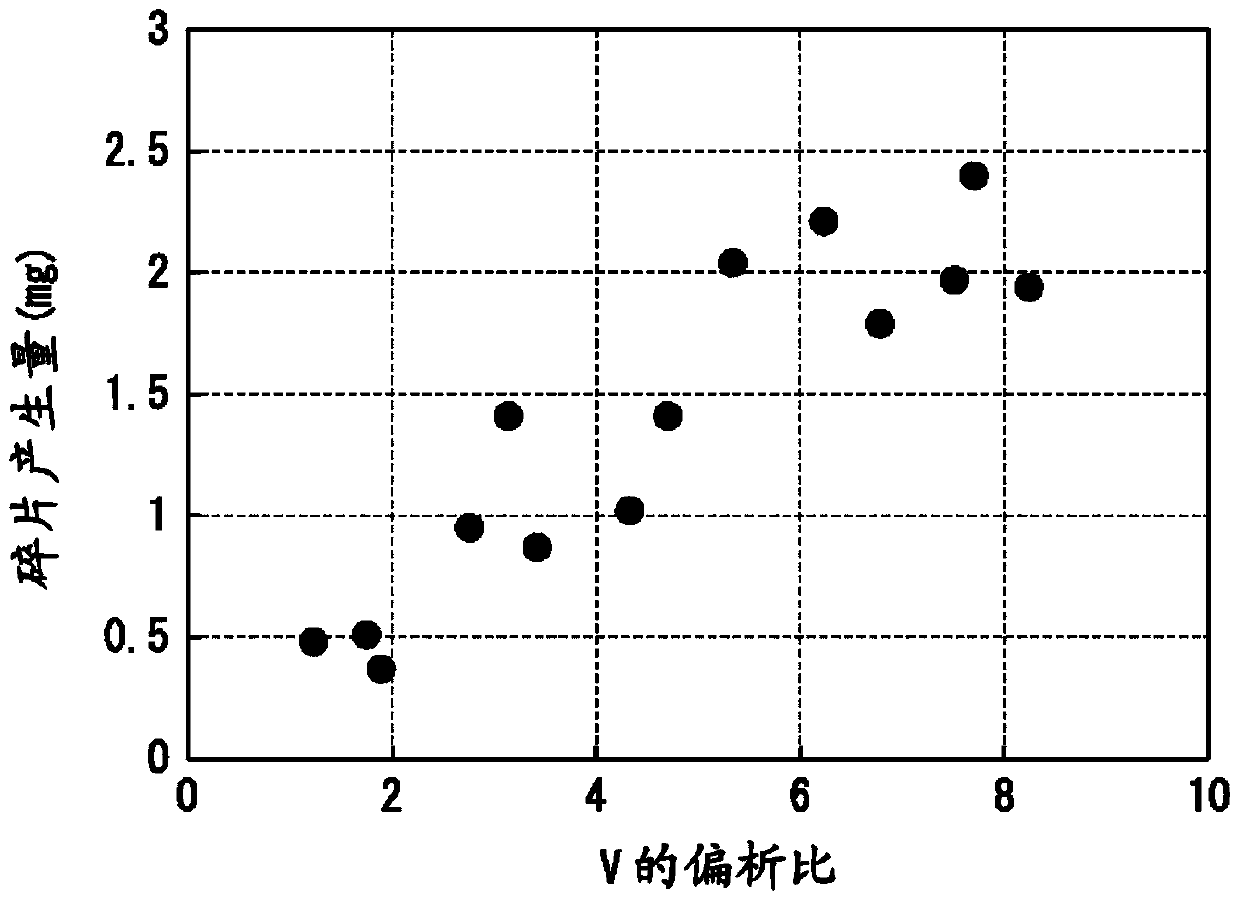

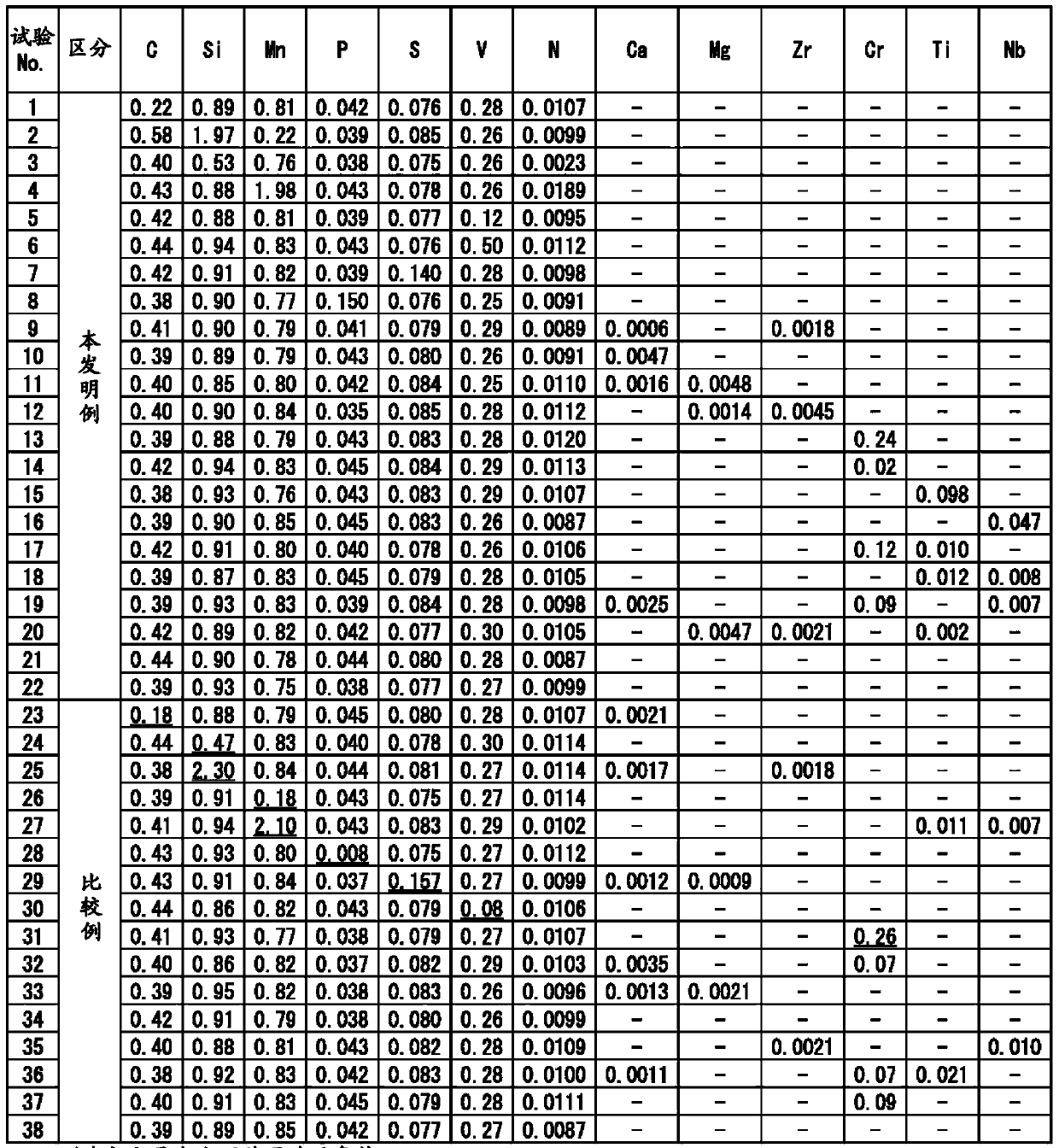

[0083] Steel ingots were produced by continuous casting of steel melted in a converter having the composition shown in Table 1, and the steel ingots were formed into billets of 162 mm square by a billeting process, and formed into bar shapes with a diameter of 56 mm by hot rolling . Furthermore, the "-" mark in the table indicates that the content of the element involved in the place recorded by the mark is below the detection threshold. And, as shown in Table 2, prepared a plurality of by adjusting the presence or absence of electromagnetic stirring in the mold in continuous casting, the degree of superheat of molten steel in the tundish, and the pressure gradient under the light pressure at the final solidification part. , so that the segregation ratio of V has changed steel. When electromagnetic stirring was performed, stirring was performed at a flow rate of 65 cm / sec. Then, the steel was poured into the mold within the range of superheat degree in the tundish of 13-52° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com