Inorganic zinc silicate workshop primer

A technology of inorganic zinc silicate and workshop primer, applied in the direction of coating, etc., can solve the problems of affecting high temperature resistance, affecting operation, generating smoke, etc., and achieve the effect of improving antirust performance and improving appearance

Inactive Publication Date: 2013-10-09

TIANCHANG JULONG TRAVEL PAINT

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The existing inorganic zinc silicate shop primers are generally added with polyvinyl butyral or other resins as plasticizers. The existence of these organic resins will inevitably affect its high temperature resistance. When the painted steel structure is welded or cut at high temperature, it will generate smoke, which will affect the operation and seriously affect the environment

In addition, due to the large proportion of zinc powder, anti-sedimentation agents must be added in the production of shop primers, which increases production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

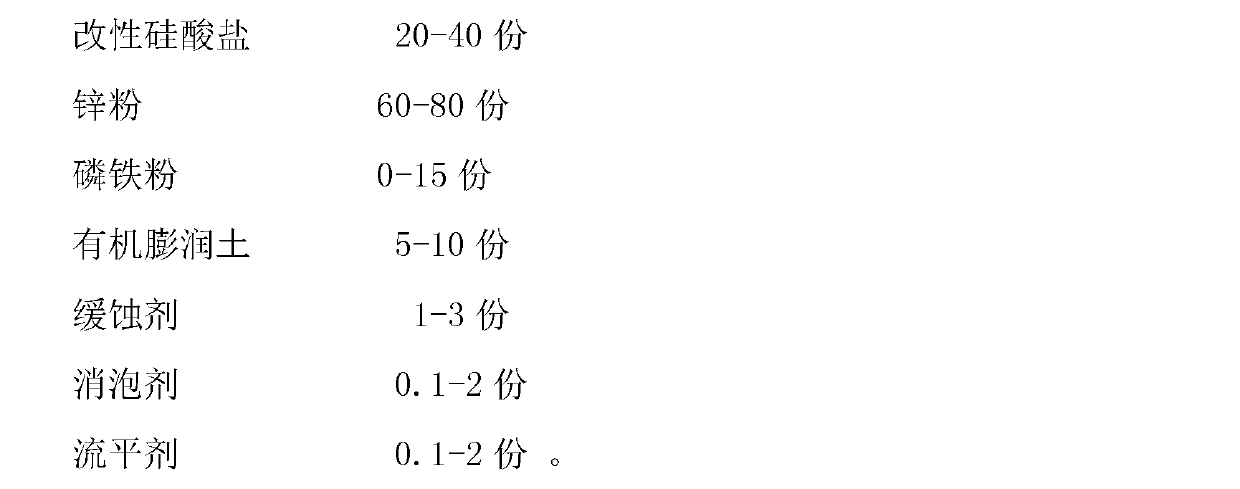

Embodiment 1

[0018]

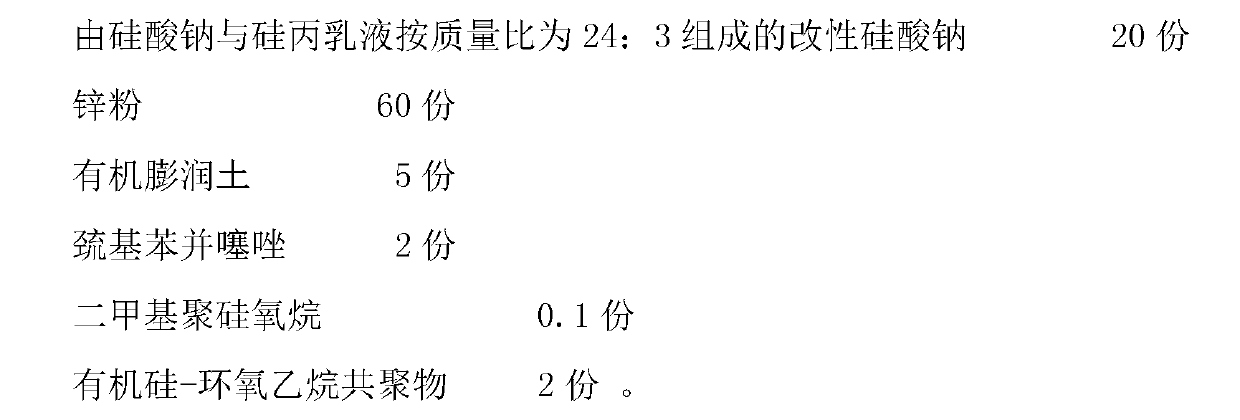

Embodiment 2

[0020]

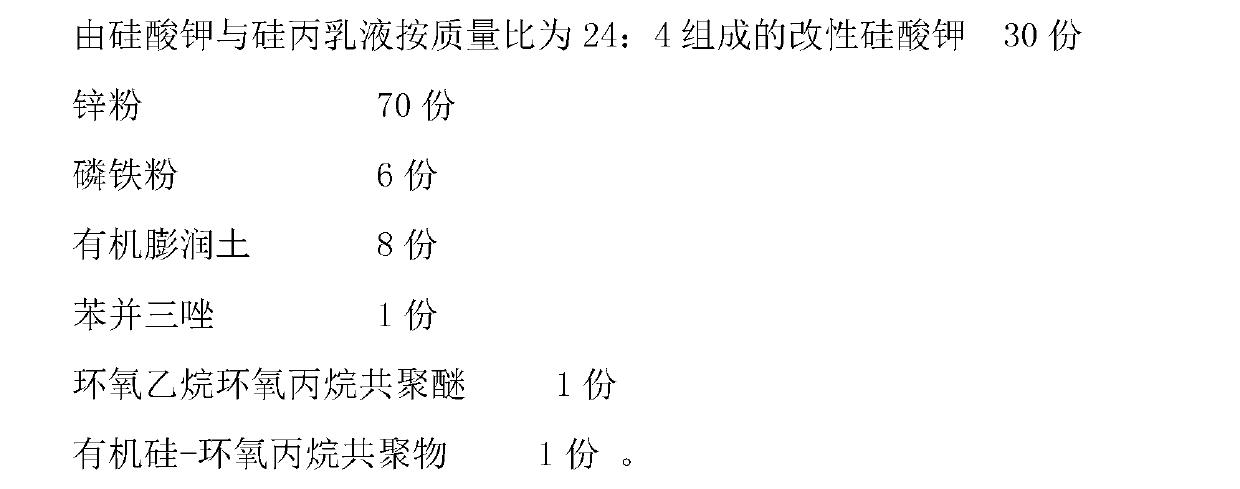

Embodiment 3

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an inorganic zinc silicate workshop primer. The Inorganic zinc silicate workshop primer is composed of modified silicate, zinc powder, ferro-phosphorus powder, organic bentonite, corrosion inhibitor, defoaming agents and flatting agents. The ferro-phosphorus powder replaces partial zinc powder in the workshop primer so as to reduce the usage amount of zinc powder, so that the production cost is reduced; meanwhile, a steel member painted with the primer reduces the production of zinc mist while welding or cutting, so that the working environment is improved, the body health of people is ensured, the cracking tendency of coatings can be greatly reduced, and the external smoothness and weather fastness of films are improved.

Description

technical field [0001] The invention relates to the technical field of coatings, in particular to an inorganic zinc silicate shop primer. Background technique [0002] The shop primer was born in the early 1950s, and its successive products include zinc-free phosphating primer, epoxy zinc-rich paint, epoxy iron red shop primer, and inorganic zinc silicate shop primer. At present, inorganic zinc silicate shop primer is the main application variety. Inorganic zinc silicate shop primer is generally composed of paint and curing agent composed of high-grade inorganic zinc silicate resin, zinc powder, additives and solvents. It is widely used in pretreatment and polishing of steel plates in metallurgy, containers, various types of transportation vehicles, and engineering machinery. It is especially suitable for rust prevention of steel structures. It is an ideal primer for metal pretreatment shot blasting and antirust maintenance. [0003] The existing inorganic zinc silicate sh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D1/00C09D7/12

Inventor 戴宇钧汪鹏程祝盆鑫孙巨福

Owner TIANCHANG JULONG TRAVEL PAINT

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com