Nanocrystal M-shaped ferrite powder and synthesis method thereof

A synthesis method and ferrite technology, applied in the field of new materials of nanocrystalline magnetic materials, can solve the problems of high production energy consumption, long preparation period, coarse product crystal grains, etc., and achieve high production efficiency, shorten calcination time, energy low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

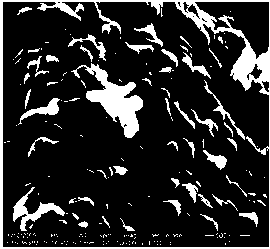

Image

Examples

Embodiment 1

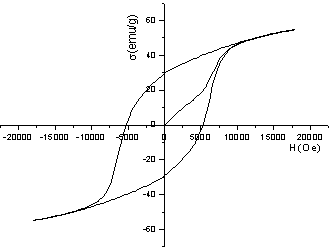

[0029] A nanocrystalline M-type ferrite powder is a single M-type ferrite powder with a particle size of about 100nm. The M, iron and oxygen contained in it are calculated by molar ratio, that is, M:Fe: O is 1:12:19;

[0030] The M is Pb.

[0031] The synthetic method of above-mentioned a kind of nanocrystalline M-type ferrite powder specifically comprises the following steps:

[0032] (1) Calculate the molar concentration of 0.2mol citric acid and 1300ml distilled water, that is, the molar concentration of citric acid in distilled water is 0.154mol / l, dissolve citric acid in distilled water, then add 0.12mol Fe salt and 0.01 mol of M metal salt, fully stirred and dissolved until clarified, adjusted the pH value of the solution to 7.0 with ammonia water, and obtained solution A;

[0033] The amount of Fe salt and M metal salt added is calculated by the molar ratio of citric acid to the total metal ions of Fe salt and M metal salt, i.e. citric acid: the total metal ion of Fe ...

Embodiment 2

[0041] A nanocrystalline M-type ferrite powder is a single M-type ferrite powder with a particle size of about 85nm. The M, iron and oxygen contained in it are calculated by molar ratio, that is, M:Fe: O is 1:12:19;

[0042] Said M is Sr.

[0043] The synthetic method of above-mentioned a kind of nanocrystalline M-type ferrite powder specifically comprises the following steps:

[0044] (1) Calculate the molar concentration of 0.36mol citric acid and 2500ml distilled water, that is, the molar concentration of citric acid in distilled water is 0.144mol / l, dissolve citric acid in distilled water, then add 0.12mol Fe salt and 0.02 mol of M metal salt, fully stirred and dissolved until clarified, adjusted the pH value of the solution to 6.2 with ammonia water, and obtained solution A;

[0045] The amount of Fe salt and M metal salt added is calculated by the molar ratio of citric acid to the total metal ions of Fe salt and M metal salt, i.e. citric acid: the total metal ion of Fe...

Embodiment 3

[0052] A nanocrystalline M-type ferrite powder is a single M-type ferrite powder with a particle size of about 65nm. The M, iron and oxygen contained in it are calculated by molar ratio, that is, M:Fe: O is 1:12:19;

[0053] Said M is Ba.

[0054] The synthetic method of above-mentioned a kind of nanocrystalline M-type ferrite powder specifically comprises the following steps:

[0055] (1) Calculate the molar concentration of 0.4mol citric acid and 2700ml distilled water, that is, the molar concentration of citric acid in distilled water is 0.148mol / l, dissolve citric acid in distilled water, then add 0.12mol Fe salt and 0.02 mol of M metal salt, fully stirred and dissolved until clarified, adjusted the pH value of the solution to preferably 6.5 with ammonia water, and obtained solution A;

[0056] The amount of Fe salt and M metal salt added is calculated by the molar ratio of citric acid to the total metal ions of Fe salt and M metal salt, i.e. citric acid: the total metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com