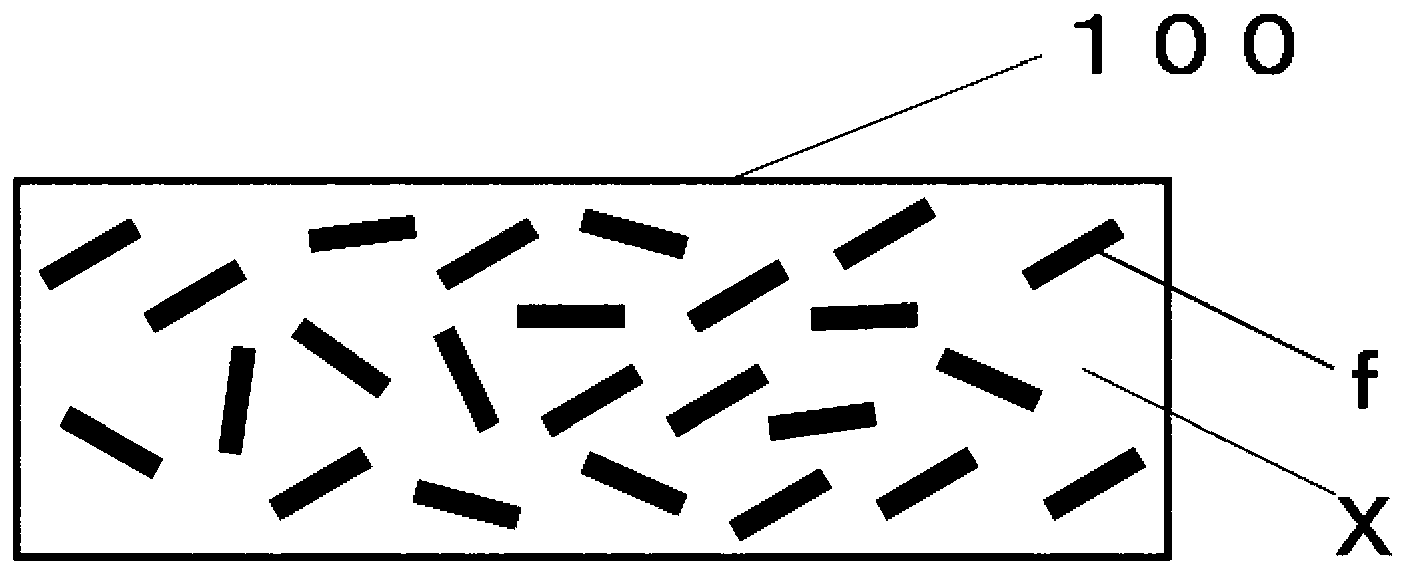

Polymer member having resistance to cigarette burns, article with resistance to cigarette burns, and method for providing resistance to cigarette burns

A polymer, polymer layer technology, applied in adhesive products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of complicated manufacturing methods, poor transparency of components, and no flame retardancy, etc. The effect of reducing the burden on the environment, high mechanical strength, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] >

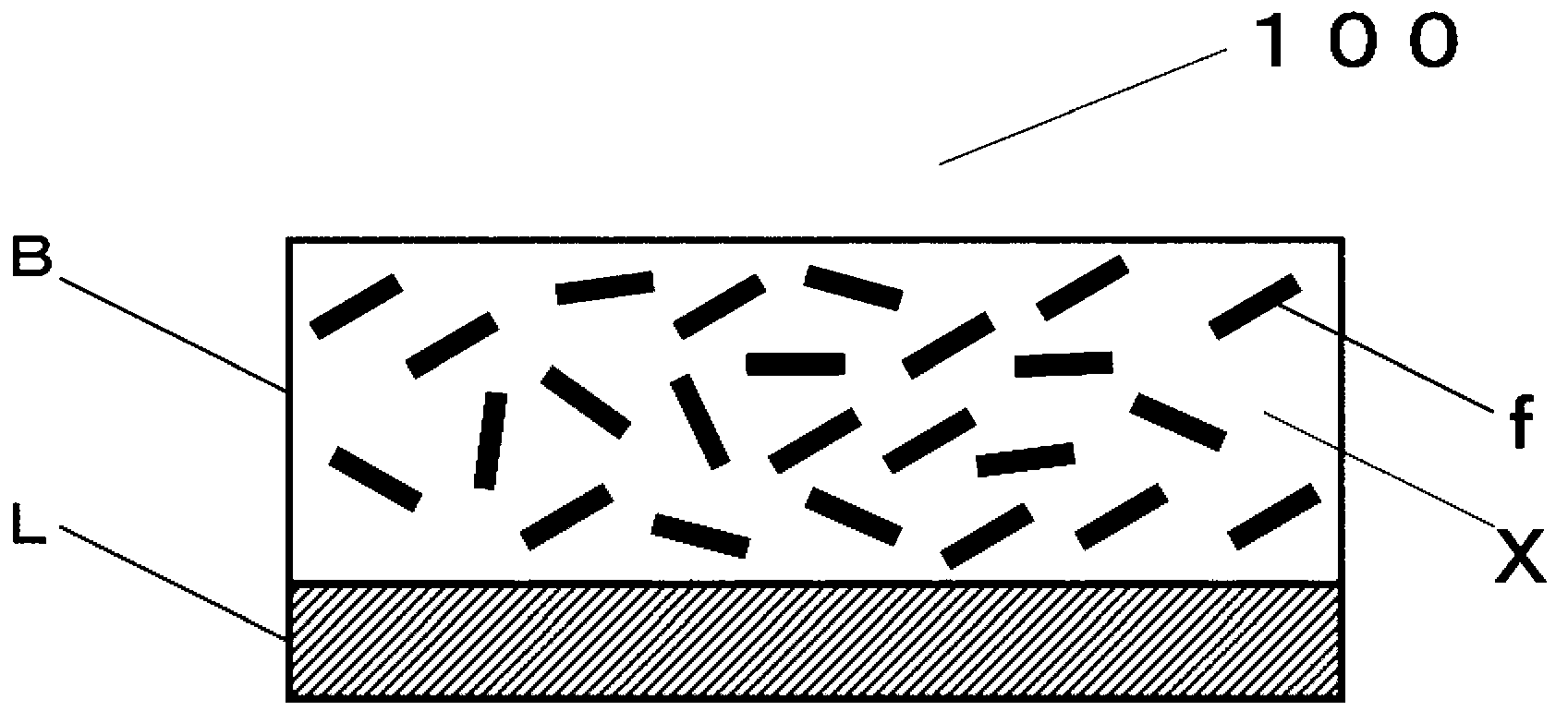

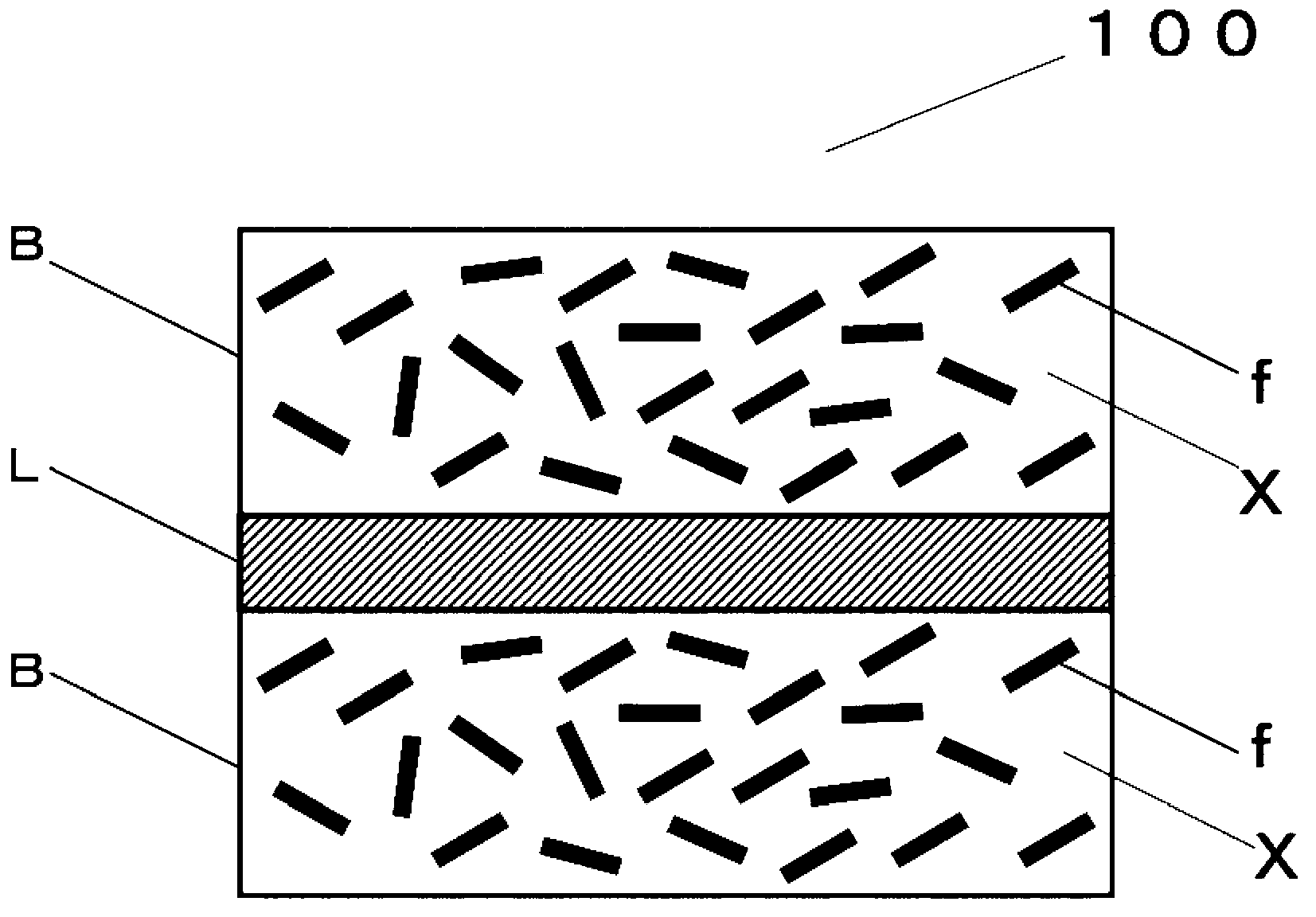

[0122] The polymeric building blocks of the present invention can be prepared by any suitable method. When the polymer member of the present invention includes the substrate layer, the member can preferably be produced by a method comprising applying, on at least one surface of the substrate layer, a polymer for forming a polymer layer. material to form layers and then cured as required. When the polymer member of the present invention includes an inorganic substrate, the member can preferably be prepared by the following method: for example, (1) comprising applying on at least one surface of the inorganic substrate for forming the polymer layer material to form a layer, and then perform curing treatment as required; or (2) comprising placing the inorganic polymer layer on a layer obtained by applying a material for forming the polymer layer on a suitable substrate A base material, a method of further applying a material for forming the polymer layer on the inorga...

Embodiment

[0177] Hereinafter, the present invention is described in more detail by means of examples, but the present invention is not limited to these examples.

[0178] It should be noted that a biaxially stretched polyethylene terephthalate film (trade name: "MRN38", manufactured by Mitsubishi Chemical Polyester Film) having a thickness of 38 μm on which a silicone-based release treatment was performed was used It was used as each cover film and base film used in each of the following Examples.

Synthetic example 1

[0179] (Synthesis Example 1) (Preparation of Slurry (a-1) Containing Layered Inorganic Compound)

[0180] 30 parts by weight of layered clay mineral (trade name: "Lucentite SPN", manufactured by Co-op Chemical Co., Ltd., shape: flat plate) was added to 100 parts by weight of 1,6-hexanediol diacrylate , and then the whole was left to stand at room temperature (25° C.) for 24 hours. A monomer mixture (cloudy) to which the layered clay minerals have been added is thus obtained. Thereafter, the monomer mixture to which the layered clay mineral had been added was irradiated with ultrasonic waves from an ultrasonic disperser (manufactured by NIPPON SEIKI CO., LTD.) at an irradiation intensity of 500 mW for 3 minutes. A slurry (a-1) containing a layered inorganic compound was thus prepared. It should be noted that due to the ultrasonic treatment, the monomer mixture to which the layered clay mineral had been added became transparent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com