Water-swelling nitrile rubber and preparation method thereof

A nitrile rubber and water-absorbing swelling technology, which is applied in the field of functional polymer materials, can solve the problems of high equipment requirements, complex compatibilizer synthesis process, and high mass loss rate, and achieve simple preparation methods, strong action force, and low mass loss. The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

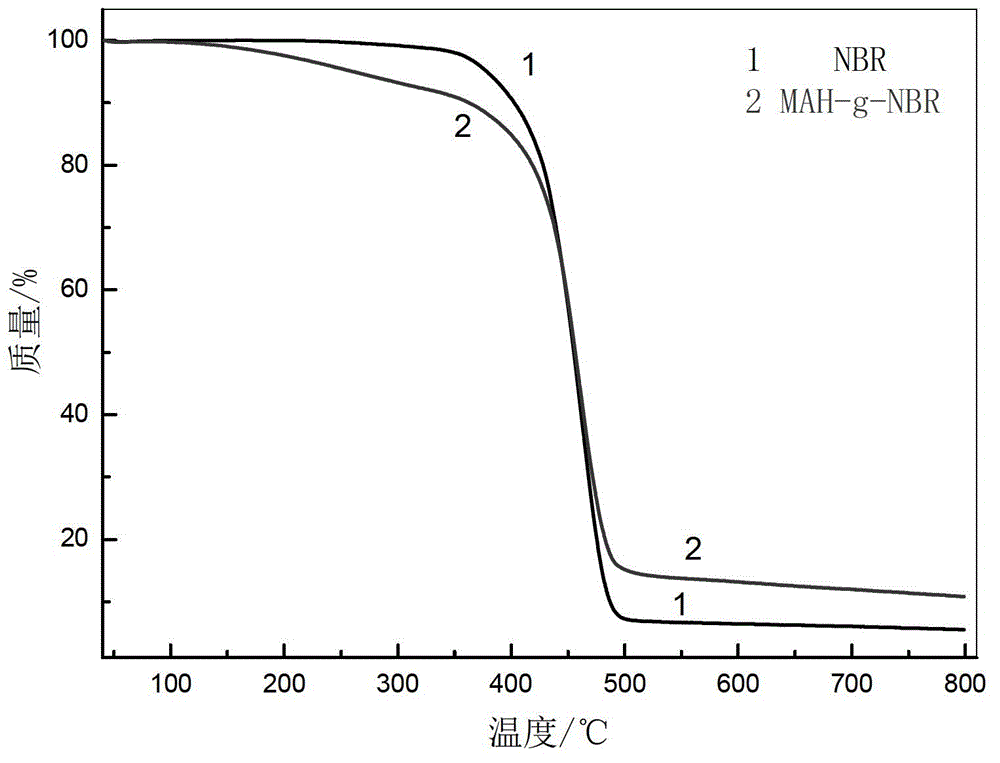

[0029] Dissolve 1g of nitrile rubber in 30mL of tetrahydrofuran, slowly add 1g of maleic anhydride and 0.16g of benzoyl peroxide in tetrahydrofuran dropwise, raise the temperature to 65°C, and react at constant temperature for 12 hours. After the reaction, the ethanol precipitated the grafted product, and then, washed several times with a large amount of distilled water, placed it in a vacuum drying oven to dry at room temperature, and after drying, extracted it with acetone solution in a Soxhlet extractor for 12 hours to obtain Malay Anhydride grafted nitrile rubber. After fully drying, the compatibilizer (maleic anhydride / nitrile rubber graft) is ready for use. Do infrared test, thermogravimetric test.

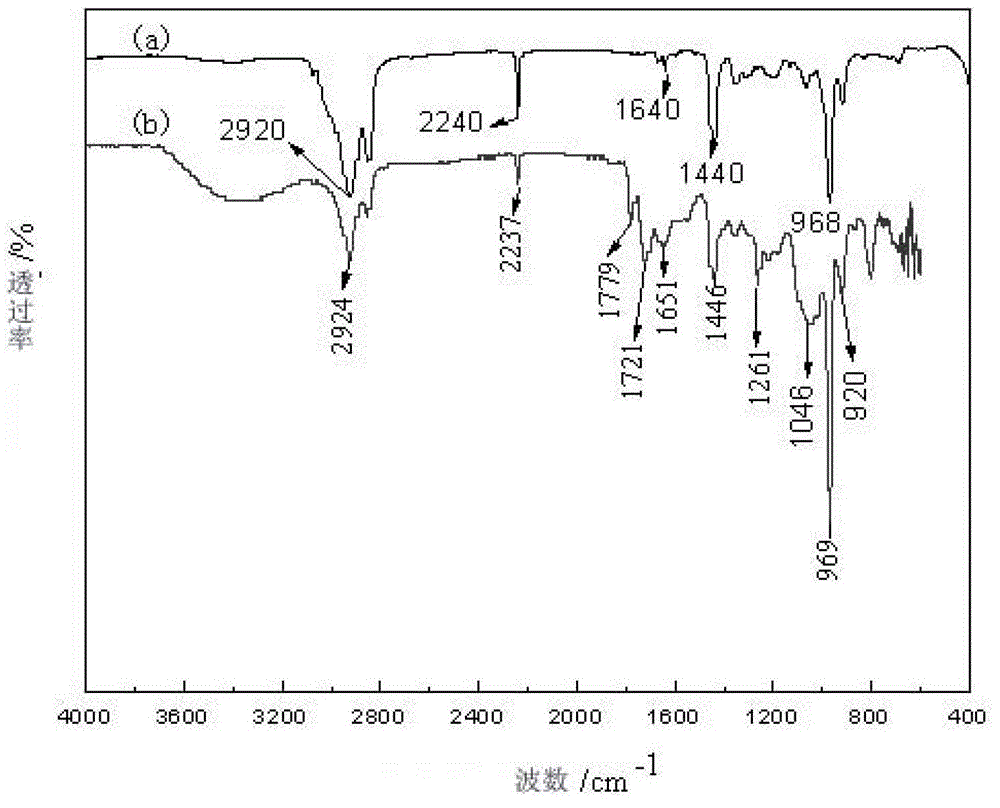

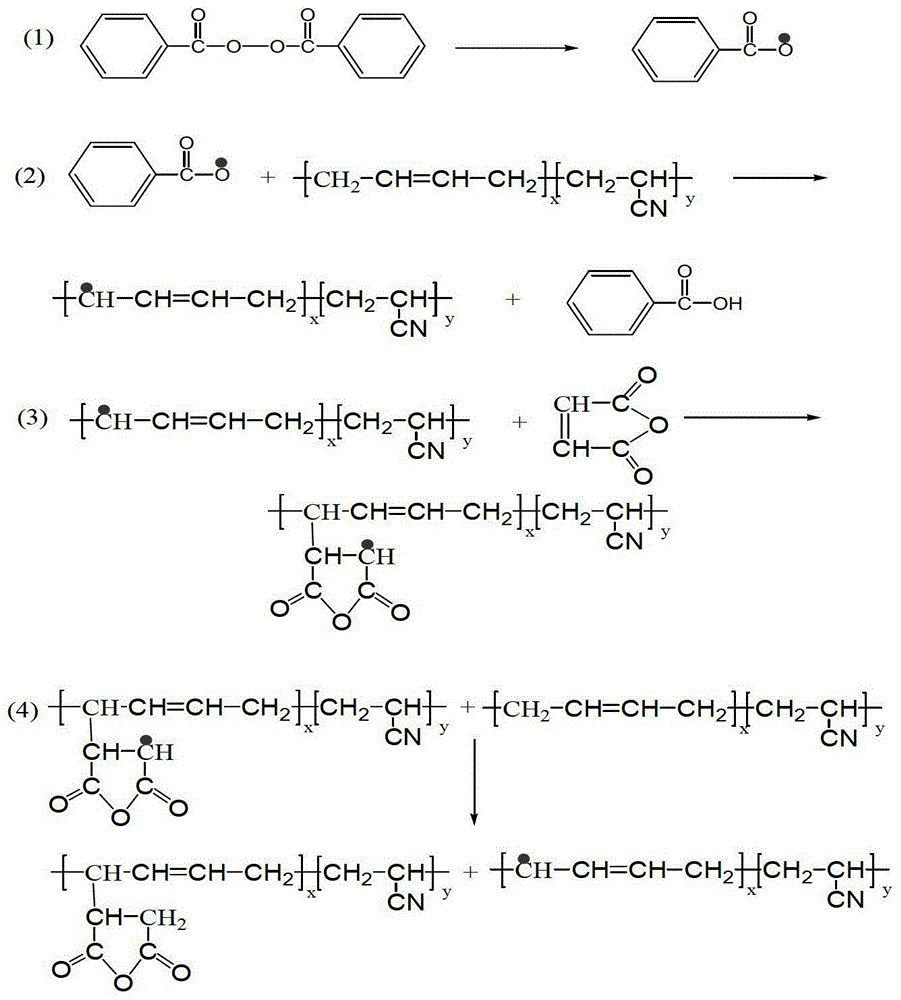

[0030] figure 1 In (a), it can be clearly seen that a series of absorption peaks around 2890-2920cm-1 are -CH 3 and -CH 2 The stretching vibration peak of C-H in , 2240cm -1 Nearby is the characteristic absorption peak of -C≡N, 1640cm -1 It is the alkene-C=C- stretchin...

Embodiment 2

[0046] After dissolving 1g of nitrile rubber with 30mL of toluene, slowly add 2.0g of maleic anhydride and 0.2g of benzoyl peroxide in toluene solution dropwise, raise the temperature to 55°C, and react at constant temperature for 10h. After the reaction, the grafted product was precipitated with distilled water, then washed several times with a large amount of distilled water, dried in a vacuum oven at room temperature, dried and extracted with a mixed solution of ethylene glycol and glacial acetic acid in a Soxhlet extractor After drying for 12 hours, the compatibilizer (maleic anhydride / nitrile rubber graft) was obtained for use.

[0047] The compatibilizer obtained in Example 2 is applied to the water-absorbing swellable nitrile rubber, and the specific implementation is the same as in Example 1, but the addition amount of the compatibilizer is kept unchanged, and the addition amount of the water-absorbent resin is changed.

[0048] Formula (amount by weight) and test resu...

Embodiment 3

[0052] Dissolve 1g of nitrile rubber in 30mL of tetrahydrofuran, slowly add 1.2g of maleic anhydride and 0.08g of benzoyl peroxide in tetrahydrofuran dropwise, raise the temperature to 63°C, and react at constant temperature for 8h. After the reaction, distilled water precipitated the grafted product, and then, washed several times with a large amount of distilled water, placed it in a vacuum drying oven and dried at room temperature, dried and extracted with acetone solution for 12 hours in a Soxhlet extractor, and obtained after drying Compatibilizer (maleic anhydride / nitrile rubber graft) spare.

[0053] The compatibilizer obtained in Example 3 is applied to water-swellable nitrile rubber, and the specific implementation method is the same as in Example 1, but the amount of the compatibilizer is kept constant, and the addition amount of sublimed sulfur is changed.

[0054] See Table 3 for the formula (consumption in parts by weight) and test results.

[0055] table 3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com