A device and process for preparing fluorine-containing polymers and fluorine-containing copolymers

A polymer and copolymer technology, applied in the field of fluorine-containing polymers and fluorine-containing copolymers, can solve the problems of uneven polymerization, increased energy consumption, and small product output, so as to avoid uneven stirring and improve production efficiency , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

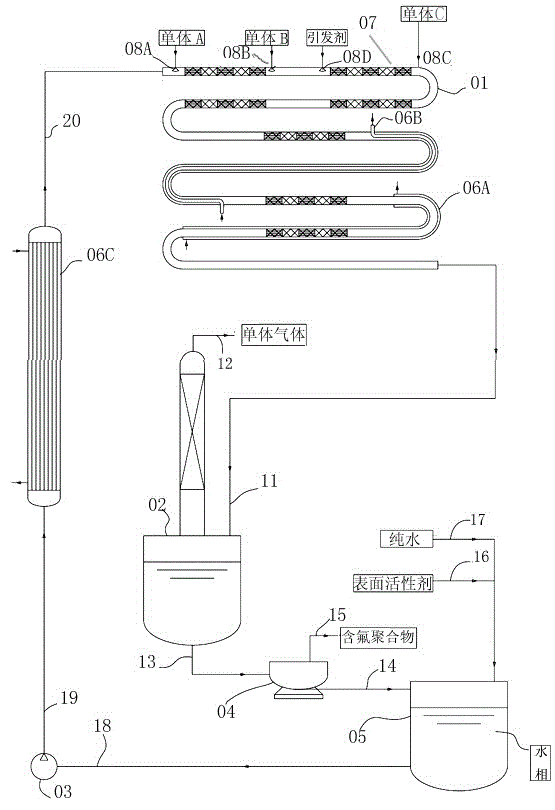

[0079] Example 1, see figure 2 , the present invention provides a device 200 for preparing fluorine-containing polymers and fluorine-containing copolymers, including: polymerization reaction pipeline 01, gas-liquid separation equipment 02, solid-liquid separation equipment 04, water phase circulation tank 05, circulation pump 03, thermostat 06C. The inlet end of the polymerization reaction pipeline 01 is connected to the outlet 20 of the thermostat 06C, and the outlet end of the polymerization reaction pipeline 01 is connected to the return pipe interface 11 of the gas-liquid separation device 02 . The liquid output end 13 of the gas-liquid separation device 02 is connected to the solid-liquid separation device, and the liquid output end 14 of the solid-liquid separation device is connected to the water phase circulation tank 05 . The gas-liquid separation device 02 is also provided with a monomer outlet 12 . The solid-liquid separation device 04 is also provided with a sol...

Embodiment 2

[0085] Embodiment 2, the structure of the device of this embodiment is the same as that of Embodiment 1; only this embodiment is an embodiment of preparing a copolymer from two kinds of fluorine-containing monomers. The specific process is as follows:

[0086] First add pure water, surfactant, etc. into the water phase circulation tank, and turn on the circulation pump to keep the water phase in a circulating state.

[0087] The initiator is sprayed into the polymerization reaction pipeline through the nozzle 08D according to the proportion, and enters into the water phase flowing in the pipeline reactor.

[0088] Monomer A is sprayed into the polymerization reaction pipeline through nozzle 08A according to the proportion in liquid form, and enters into the water phase flowing in the polymerization reaction pipeline; monomer B is sprayed into in liquid form through nozzle 08B according to the proportion Polymerization tubes, into the aqueous phase already flowing in the polym...

Embodiment 3

[0091] Embodiment 3, the structure of the device of this embodiment is the same as that of Embodiment 1; only this embodiment is an embodiment of preparing a copolymer from three kinds of fluorine-containing monomers. The specific process is as follows:

[0092] First add pure water, surfactant, etc. into the water phase circulation tank, and turn on the circulation pump to keep the water phase in a circulating state.

[0093] The initiator is sprayed into the polymerization reaction pipeline through the nozzle 08D according to the proportion, and enters into the water phase flowing in the pipeline reactor.

[0094]Monomer A is sprayed into the polymerization reaction pipeline through nozzle 08A according to the proportion in liquid form, and enters into the water phase flowing in the polymerization reaction pipeline; monomer B is sprayed into in liquid form through nozzle 08B according to the proportion The polymerization reaction pipeline enters the water phase that has flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com