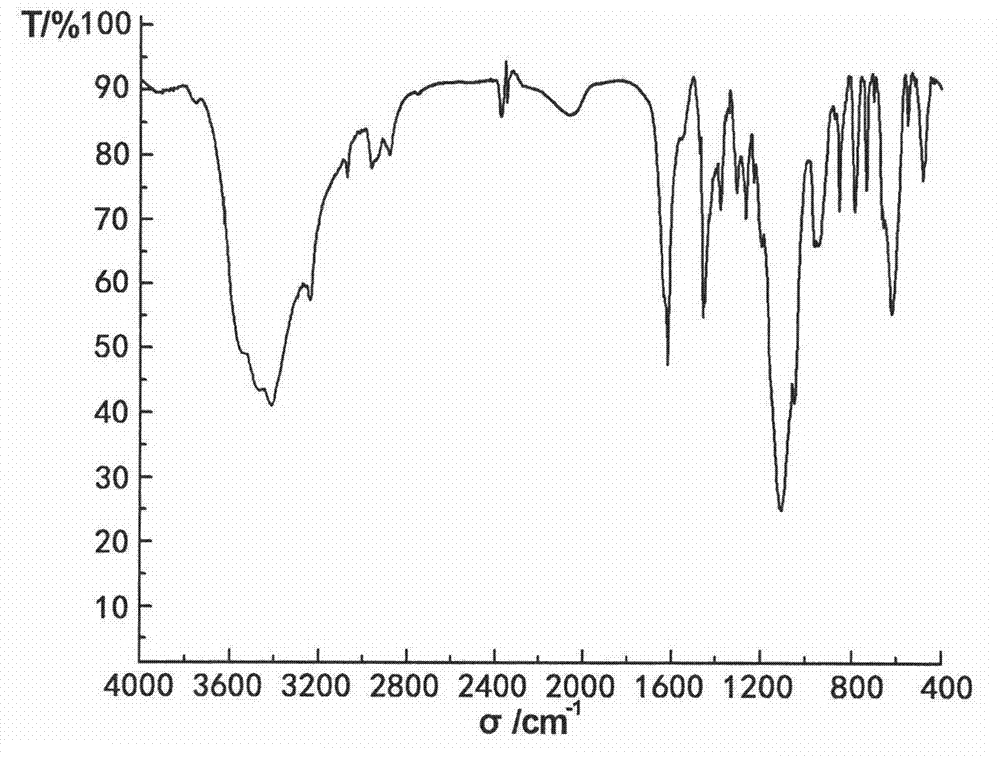

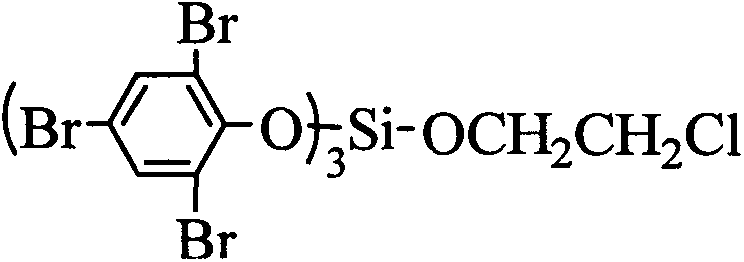

A kind of flame retardant tris(tribromophenyl)chloroethyl silicate compound and preparation method thereof

A technology of tribromophenyl and trisilicate, applied in the direction of silicon organic compounds, can solve the problems of high price, narrow use range, and restrictions, and achieve the effects of low production cost, convenient operation, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

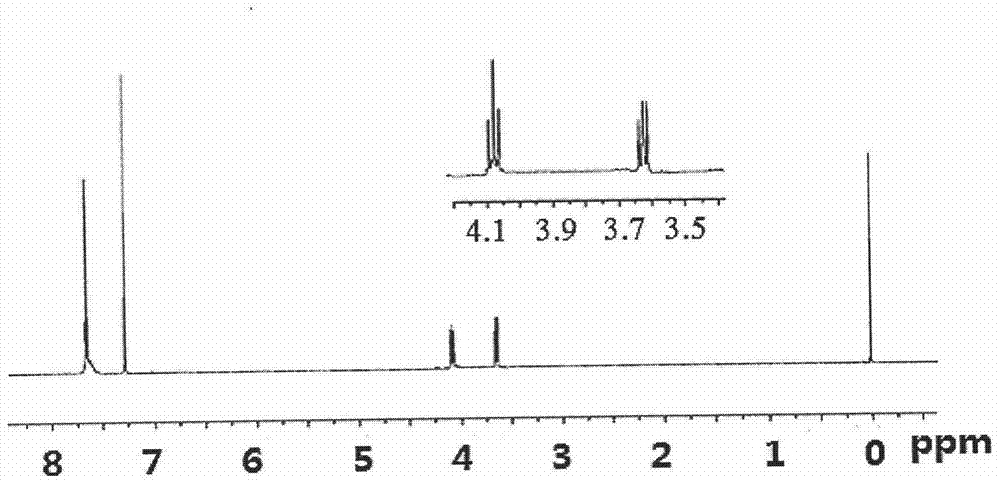

Embodiment 1

[0028] Embodiment 1 In the 500ml four-neck flask that stirrer, thermometer, dropping funnel and high-efficiency reflux condenser are equipped with and an extremely stretchable and expandable soft sealing sleeve is housed on the condenser upper mouth, replace the nitrogen in the bottle with nitrogen. After the air, add 100ml toluene and 8.50g (0.05mol) silicon tetrachloride, start stirring, under the cooling of ice-water bath, feed 2.20g (0.05mol) ethylene oxide under the liquid surface, control the temperature at the speed of feeding. Below 20°C, after passing through, add 49.62g (0.15mol) of tribromophenol, raise the temperature to 100°C, keep the temperature for 10 hours, after the hydrogen chloride is released, cool down to 40°C, and then add ethylene oxide under the liquid surface to remove A small amount of free acid in the reaction solution, check the pH of the reaction solution = 5 to 6 as the end point, and distill off the solvent (recycled for use) and a small amount o...

Embodiment 2

[0029] Example 2 In a 500ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and an extremely flexible and expandable soft seal at the top of the condenser, replace the nitrogen in the bottle with nitrogen. After the air, add 100ml of xylene and 8.50g (0.05mol) of silicon tetrachloride, start stirring, under the cooling of ice-water bath, pass 2.20g (0.05mol) of ethylene oxide under the liquid surface, and control the temperature with the speed of entry Below 20°C, after passing through, add 49.62g (0.15mol) of tribromophenol, raise the temperature to 110°C, keep the temperature for 8 hours, after the hydrogen chloride is released, cool down to 40°C, and then pass in ethylene oxide under the liquid surface Remove a small amount of free acid in the reaction solution, check the pH of the reaction solution = 5 to 6 as the end point, and distill off the solvent (recycled for use) and a small amount of low boiling poi...

Embodiment 3

[0030] Example 3 In a 500ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel and a high-efficiency reflux condenser and an extremely stretchable and expandable soft seal sleeve at the upper mouth of the condenser, replace the nitrogen in the bottle with nitrogen. After air, add 100ml of chlorobenzene and 8.50g (0.05mol) of silicon tetrachloride, start stirring, under the cooling of ice-water bath, pass 2.20g (0.05mol) of ethylene oxide under the liquid surface, and control the temperature with the speed of introduction Below 20°C, after passing through, add 49.62g (0.15mol) of tribromophenol, raise the temperature to 105°C, keep the temperature for 9 hours, after the hydrogen chloride is released, cool down to 40°C, and then add ethylene oxide under the liquid surface Remove a small amount of free acid in the reaction solution, check the pH of the reaction solution = 5 to 6 as the end point, and distill off the solvent (recycled for use) and a small a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com