High-temperature leveling agent, and preparation method and application thereof

A technology of high-temperature leveling agent and polyester polyether, which is applied in dyeing, textiles and papermaking, can solve the problems of complex production process, high cost, and lack of finishing effect, and achieve uniform color of fabrics, cost of raw materials and manufacturing The effect of low cost, good antistatic properties and hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

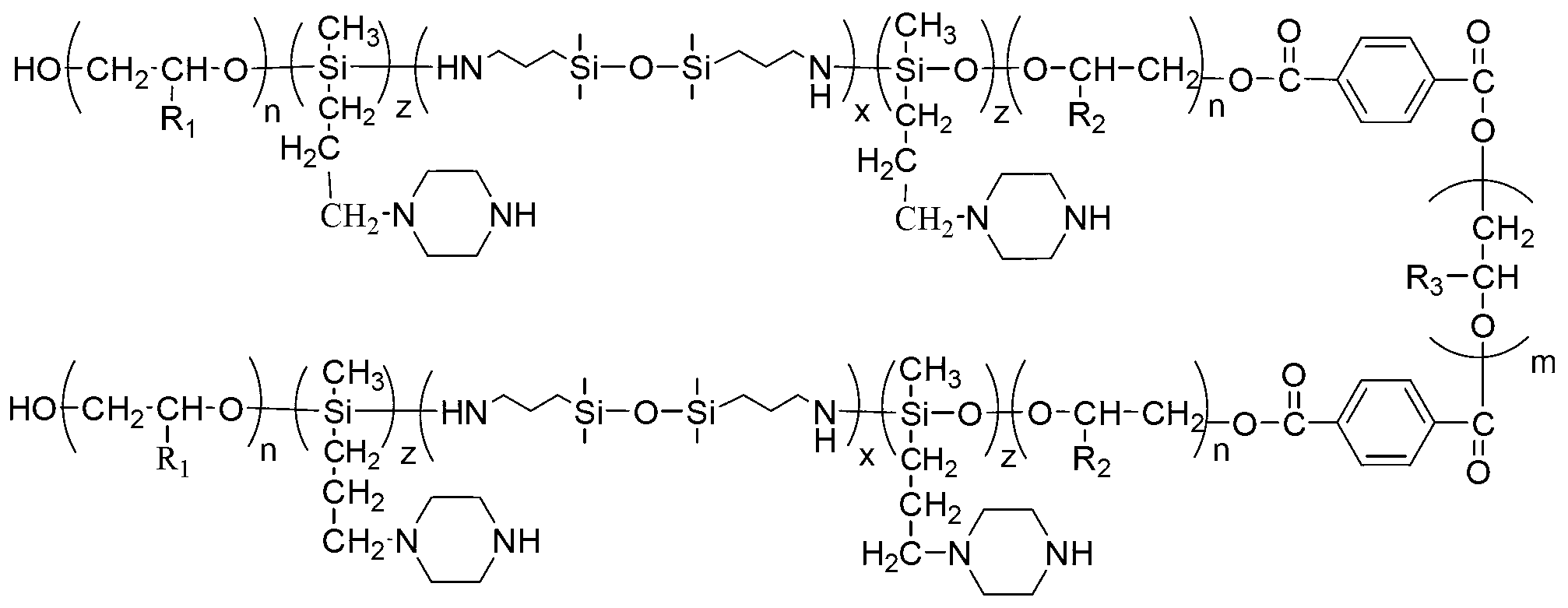

Method used

Image

Examples

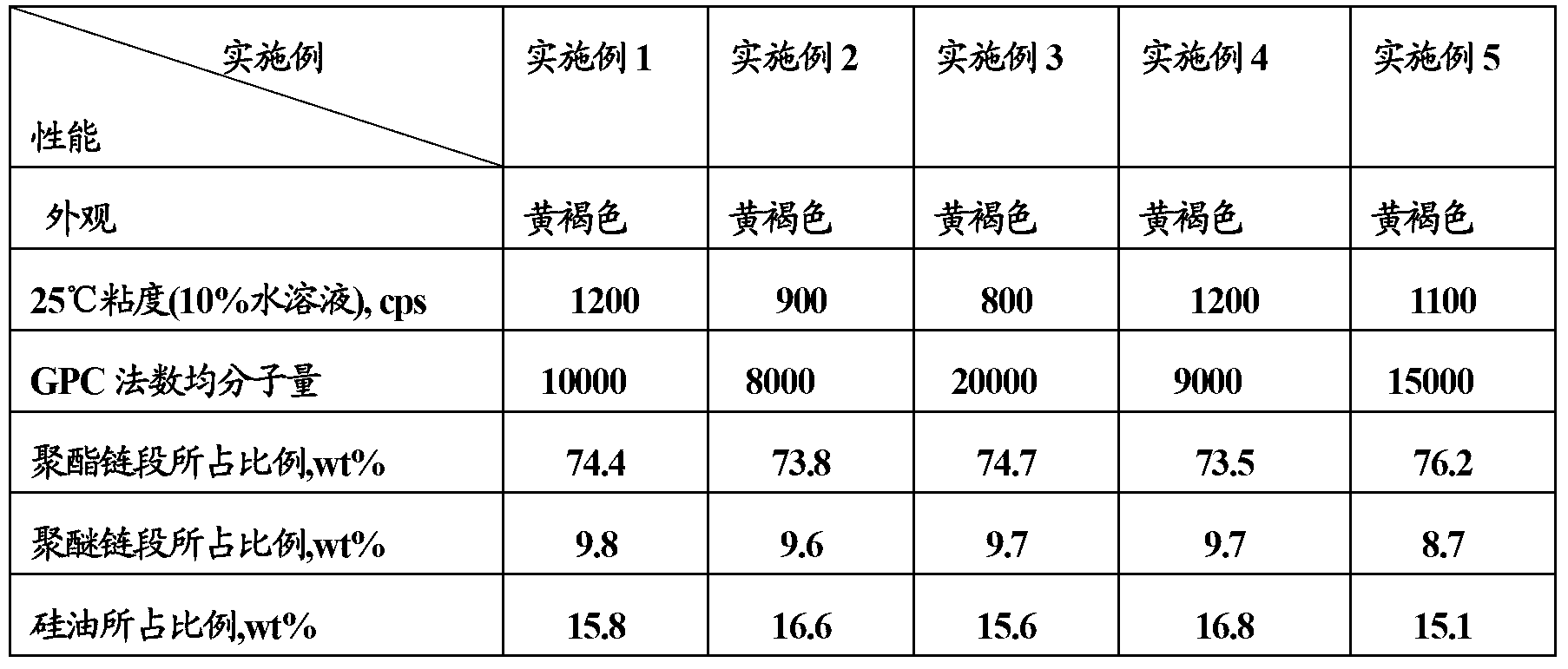

Embodiment 1

[0024] A kind of high temperature leveling agent, it is prepared by following steps:

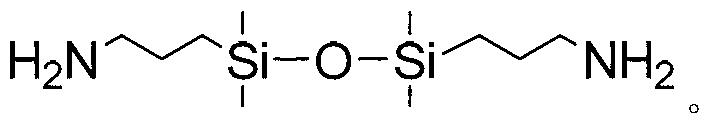

[0025] (1) Weigh 800 grams of polyethylene glycol (PEG4000), 150 grams of ethylene glycol, 125 grams of dihydroxypolyether, 140 grams of dimethyl terephthalate, and 150 grams of amino-terminated double-header silicone, 50g of 3-piperazinepropylmethyldimethoxysilane, 10g of magnesium acetate;

[0026] (2) Put the above materials into the reaction kettle, raise the temperature to 140°C and keep it for 180 minutes, then continue to raise the temperature to 220°C and keep it for 60 minutes. Then carry out polymerization at a vacuum degree of -0.08MPa and a temperature of 240°C to generate a polyester polyether silicone oil block copolymer, which is cooled to 190°C and discharged to obtain a polyester polyether silicone oil block copolymer;

[0027] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), polyethylene glycol (200) monostearate and water in a weight rati...

Embodiment 2

[0029] A kind of high temperature leveling agent, it is prepared by following steps:

[0030] (1) Weigh 900 grams of polyethylene glycol (PEG2000), 140 grams of ethylene glycol, 140 grams of dihydroxypolyether, 165 grams of dimethyl terephthalate, and 180 grams of amino-terminated double-header silicone, 3-piperazinepropylmethyldimethoxysilane 60g, zinc acetate 6g;

[0031] (2) Put the above materials into the reaction kettle, raise the temperature to 150°C and keep it for 180 minutes, then continue to raise the temperature to 230°C and keep it for 60 minutes. Then carry out polymerization, carry out polymerization at a vacuum degree of -0.08MPa, and a temperature of 260°C to generate a polyester polyether silicone oil block copolymer, and discharge it after cooling down to 200°C to obtain a polyester polyether silicone oil block copolymer;

[0032] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), polyethylene glycol (200) monostearate and wa...

Embodiment 3

[0034] A kind of high temperature leveling agent, it is prepared by following steps:

[0035] (1) Weigh 700 grams of polyethylene glycol (PEG2000), 125 grams of ethylene glycol, 125 grams of dihydroxypolyether, 130 grams of dimethyl terephthalate, and 150 grams of amino-terminated double-header silicone, 50 grams of 3-piperazinepropylmethyldimethoxysilane, 10 grams of calcium acetate;

[0036] (2) Put the above materials into the reaction kettle, raise the temperature to 170°C and keep it for 180 minutes, continue to raise the temperature to 220°C and keep it for 60 minutes, then carry out polymerization at a vacuum degree of -0.09MPa and a temperature of 250°C to form The polyester polyether silicone oil block copolymer is discharged after cooling down to 200°C to obtain the polyester polyether silicone oil block copolymer;

[0037] (3) Mix the polyester polyether silicone oil block copolymer obtained in step (2), polyethylene glycol (600) monostearate and water in a weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com