Tufted carpet stretcher device to prevent base fabric from swinging

A tufted carpet and base fabric technology, applied in the field of tufted carpet processing equipment, can solve problems such as affecting the quality of tufted carpets, achieve good support, eliminate swing, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

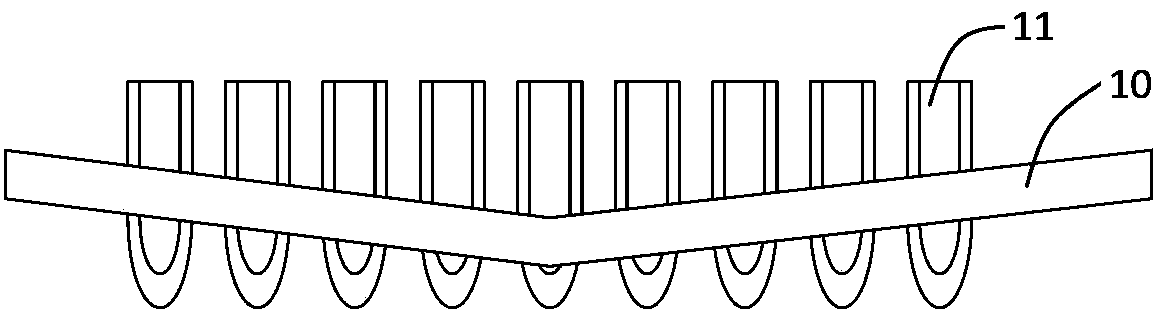

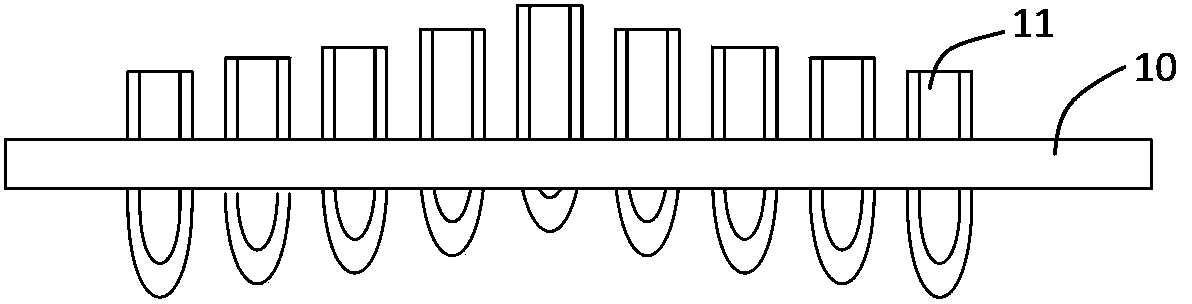

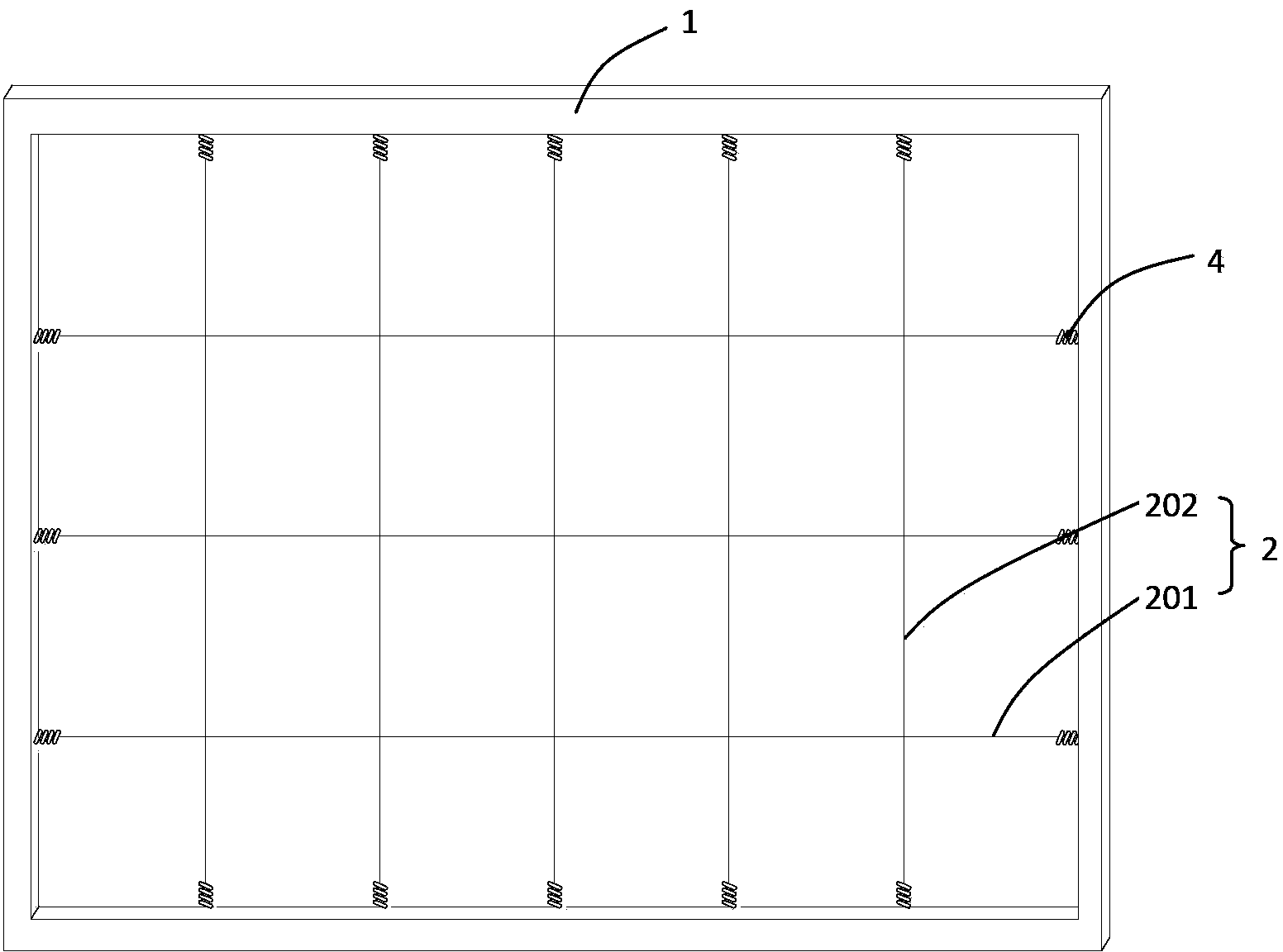

[0027] Such as figure 2 As shown, the base fabric stretcher 1 is provided with several steel wire strips 2, and both ends of each steel wire 2 are connected to the base fabric stretcher 1 through elastic members. During tufting, the base fabric stretcher 1 can effectively support the base fabric and prevent the base fabric from swinging (moving along the tufting direction of the tufting needles 6).

Embodiment 2

[0029] Embodiment 2 is an improvement made on the basis of Embodiment 1, as image 3 , Figure 4 As shown, several slide pipes 3 are connected in series on each steel wire bar 2 . The slide tube 3 can make the tufting needling needles 6 quickly stagger for tufting.

[0030] Several steel wire strips 2 can be arranged in many ways on the base fabric stretcher 1. In the present invention, several steel wire strips 2 are arranged in a criss-cross pattern, which includes a plurality of horizontal steel wire strips 201 positioned on the first layer and a plurality of horizontal steel wire strips. Root is positioned at the longitudinal steel wire strip 202 of second layer, as figure 2 , image 3 , Figure 4 As shown, several steel wire strips 2 include a plurality of horizontal steel wire strips 201 that are close to the base fabric and perpendicular to the base cloth feeding direction (located on the first layer) and a plurality of horizontal steel wire strips 201 that are far...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com