Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about "Poultry shackles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

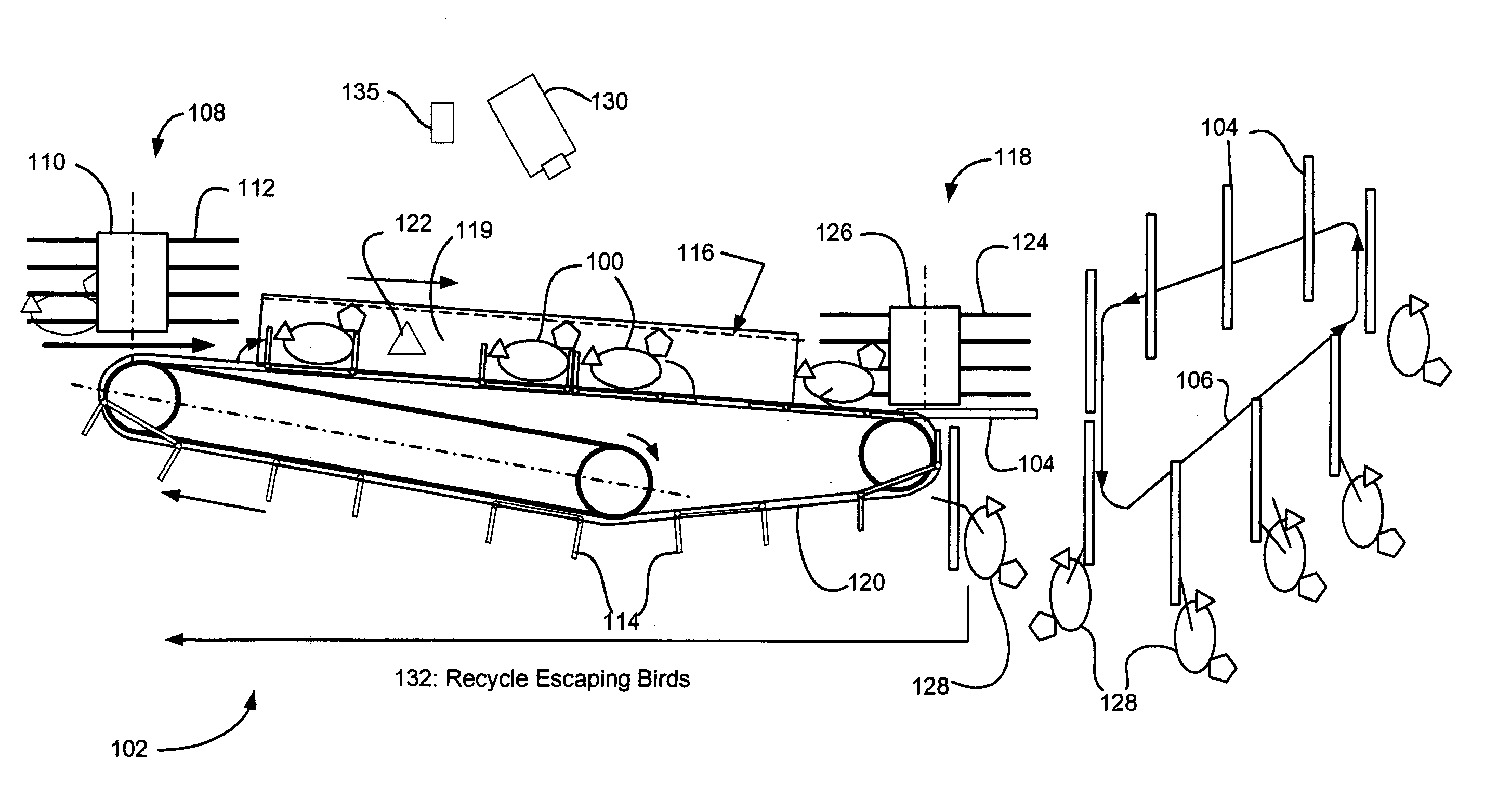

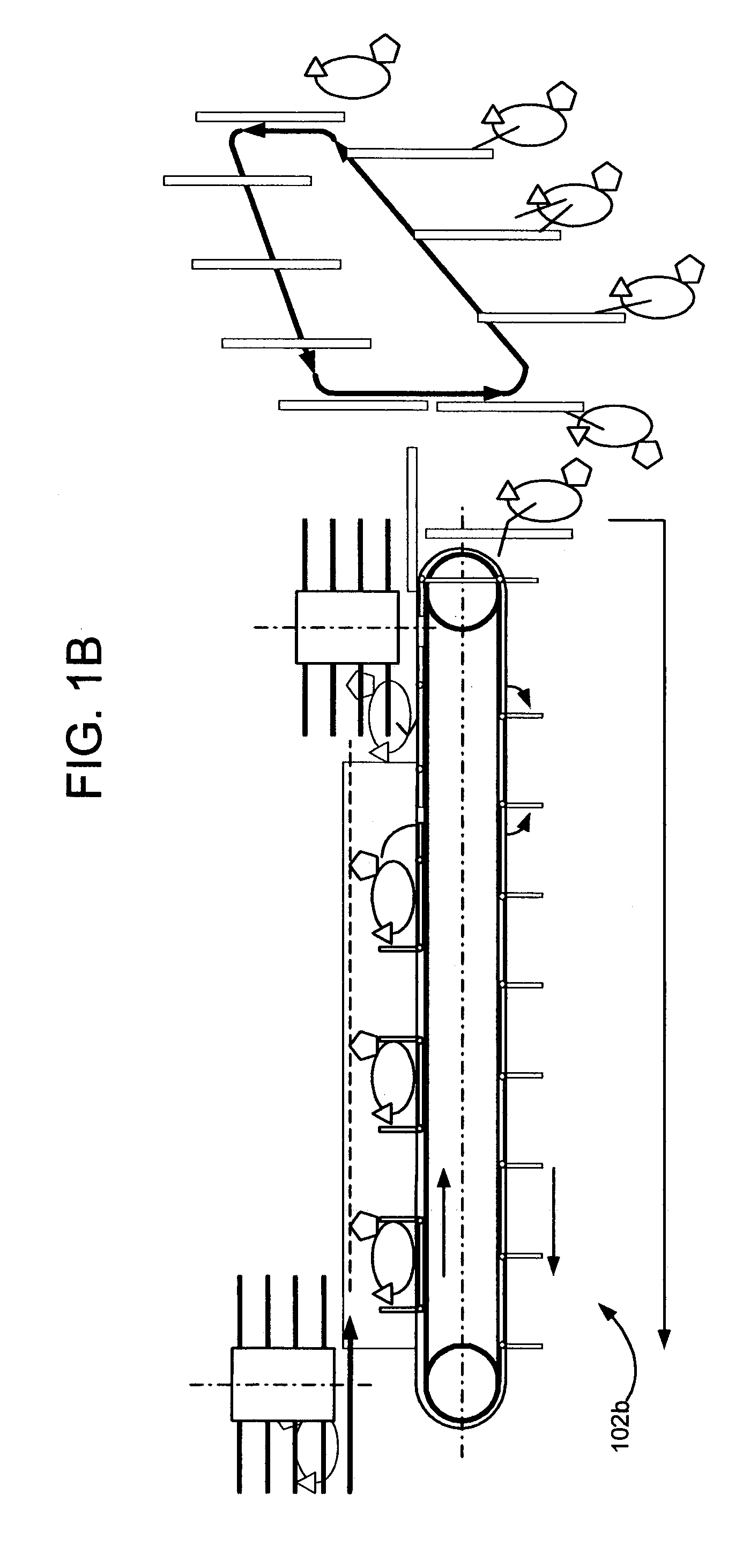

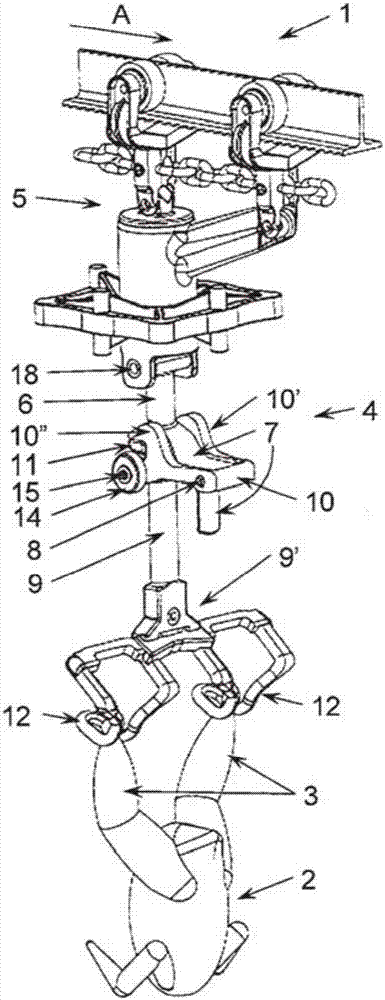

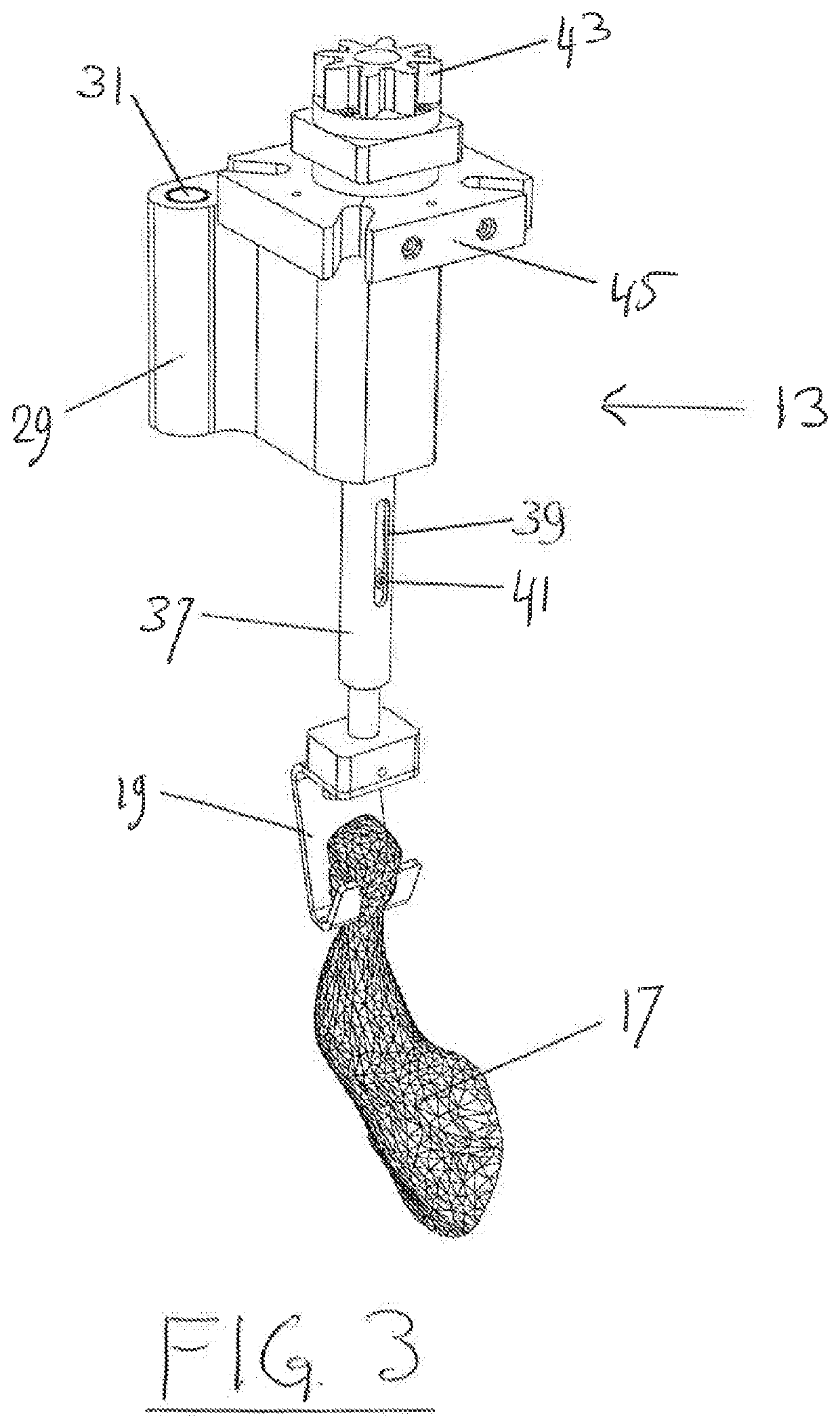

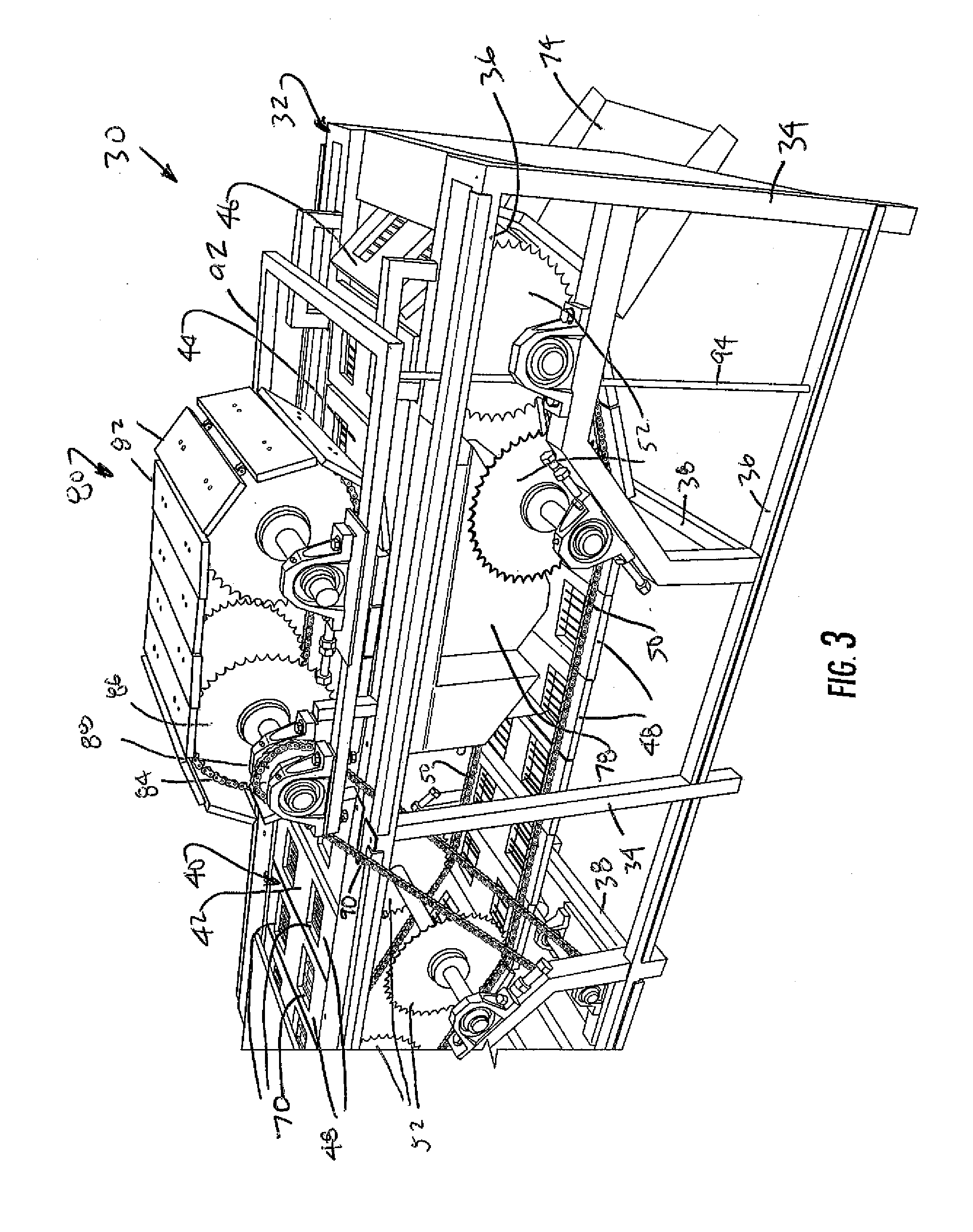

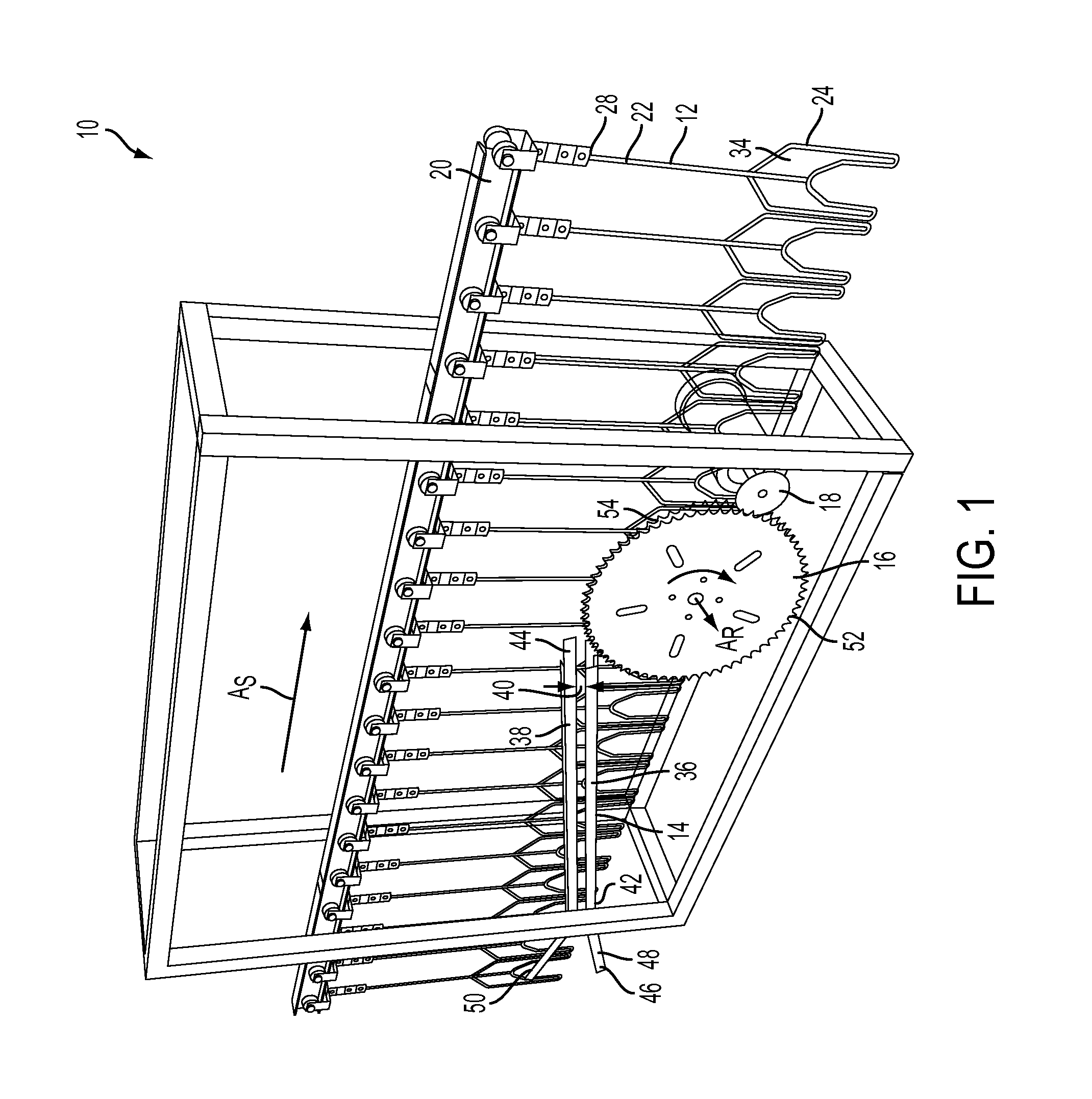

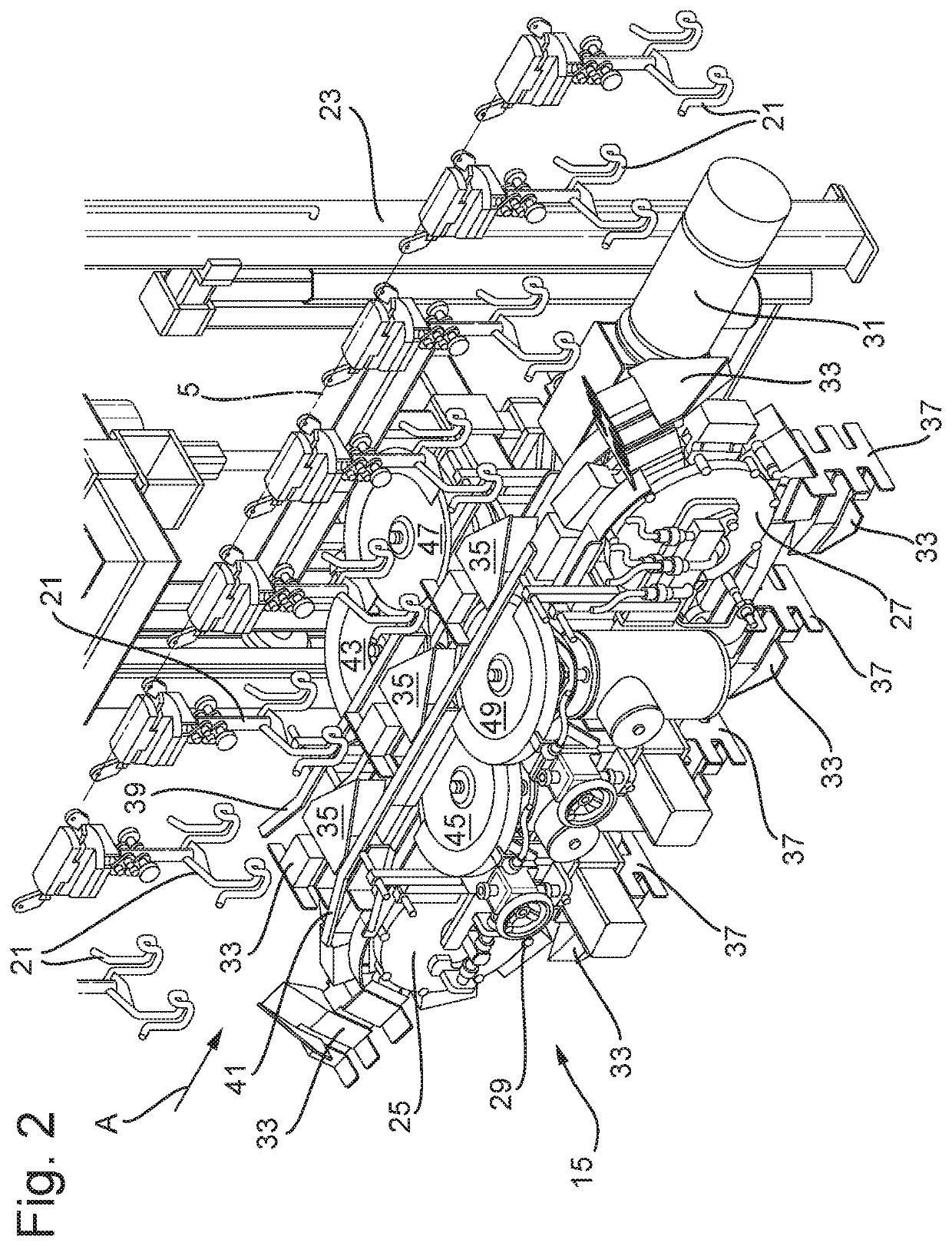

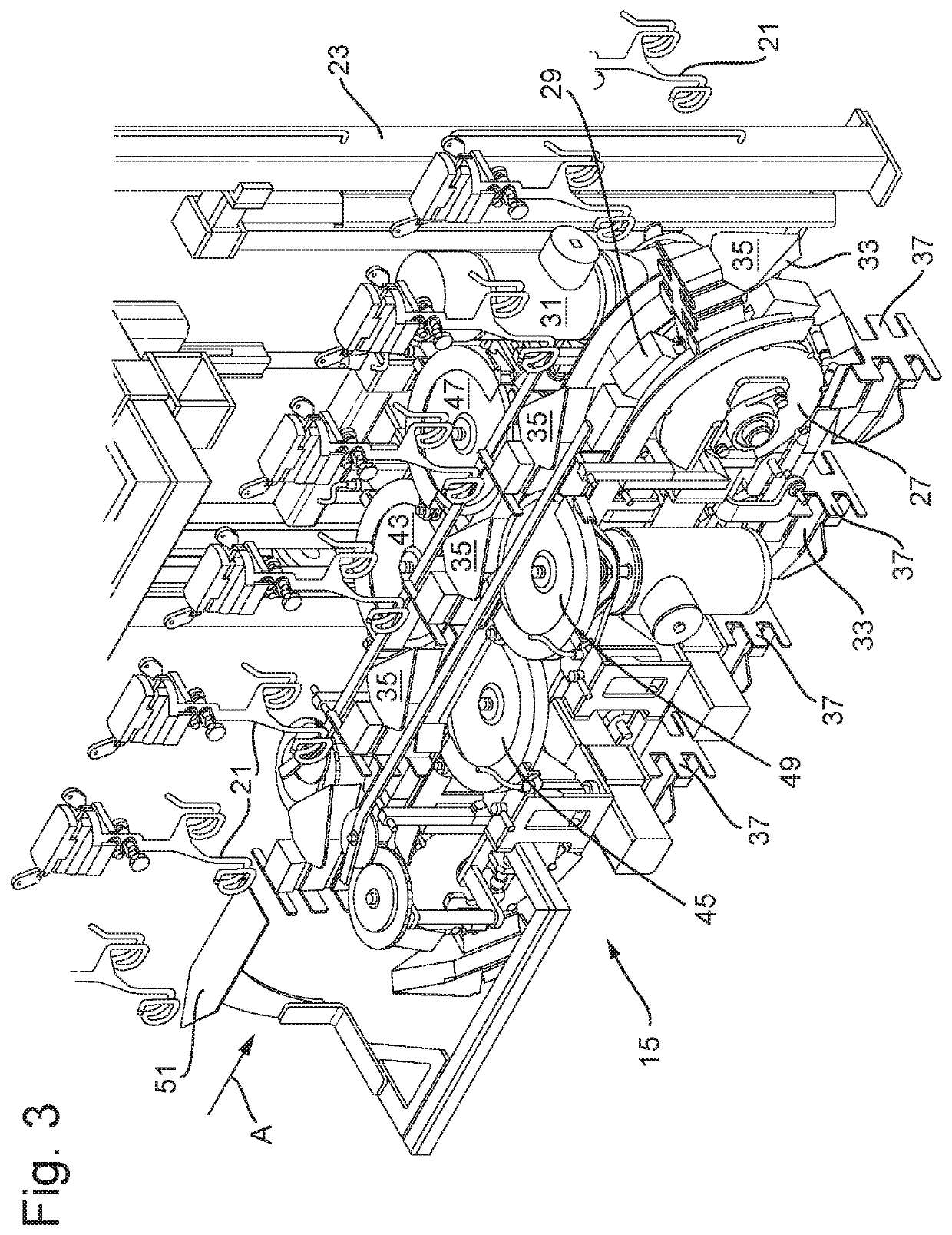

Automated feet-gripping system

InactiveUS7134956B2Slaughtering animals fettering apparatusSlaughtering stands/spreadersDead bodyShackle

A system and method for transferring live objects, such as chickens, to a shackle line are presented. The system and method include introducing a plurality of live objects to a singulator. The singulator isolates the individual live objects and places them in a pallet on a conveyor. The system may detect and remove cadavers from amongst the live objects. The conveyor leads the live objects to a grasper. The grasper positions the legs of the live objects so that a shackler can secure the legs of the live objects with a shackle. The live objects and the shackle are then inverted and passed on to a shackle line. The shackle line may be a kill line buffer or a kill line.

Owner:GEORGIA TECH RES CORP

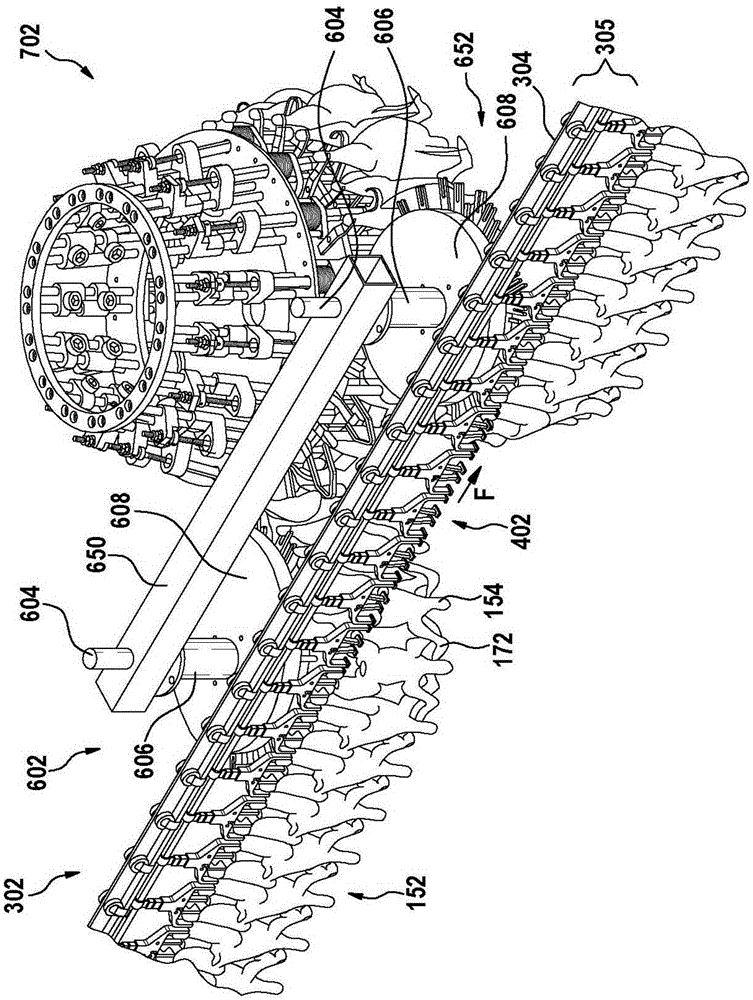

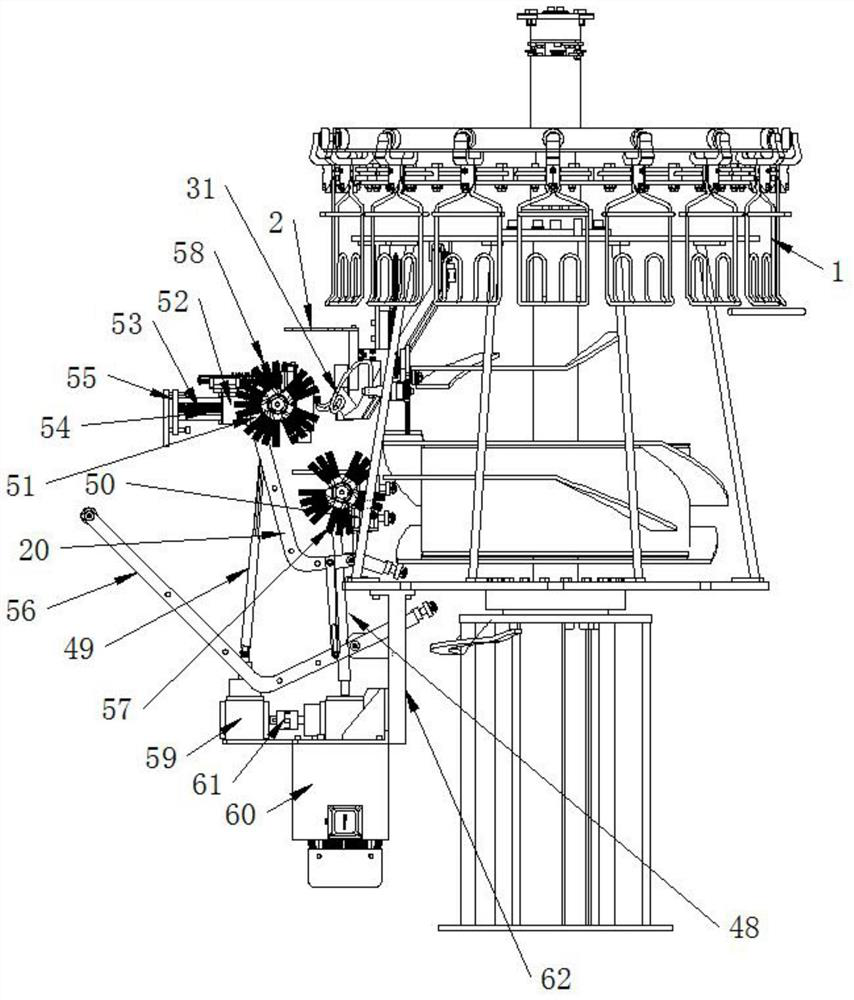

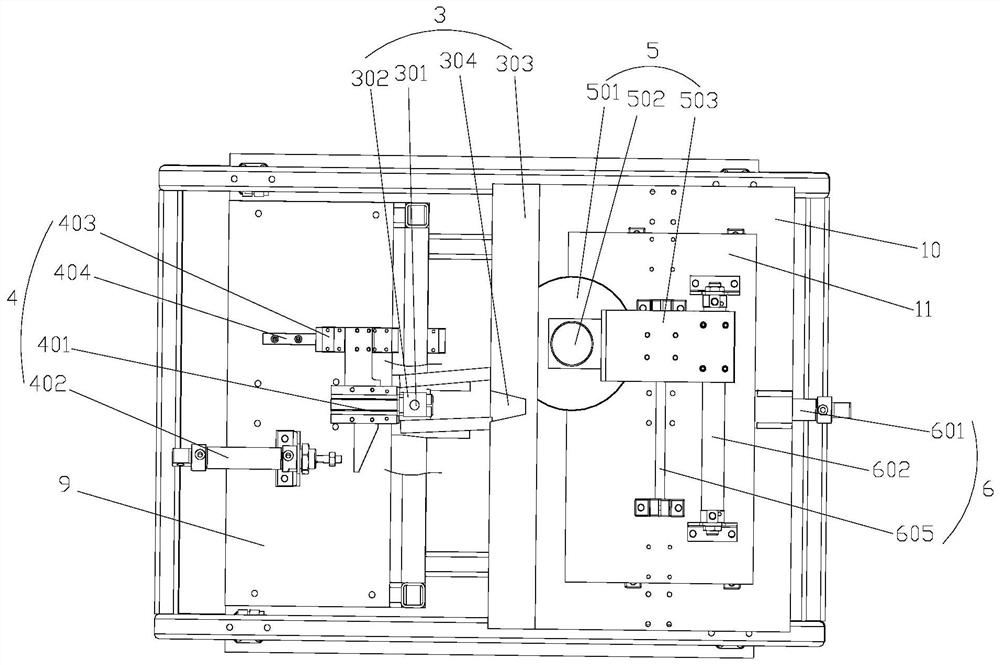

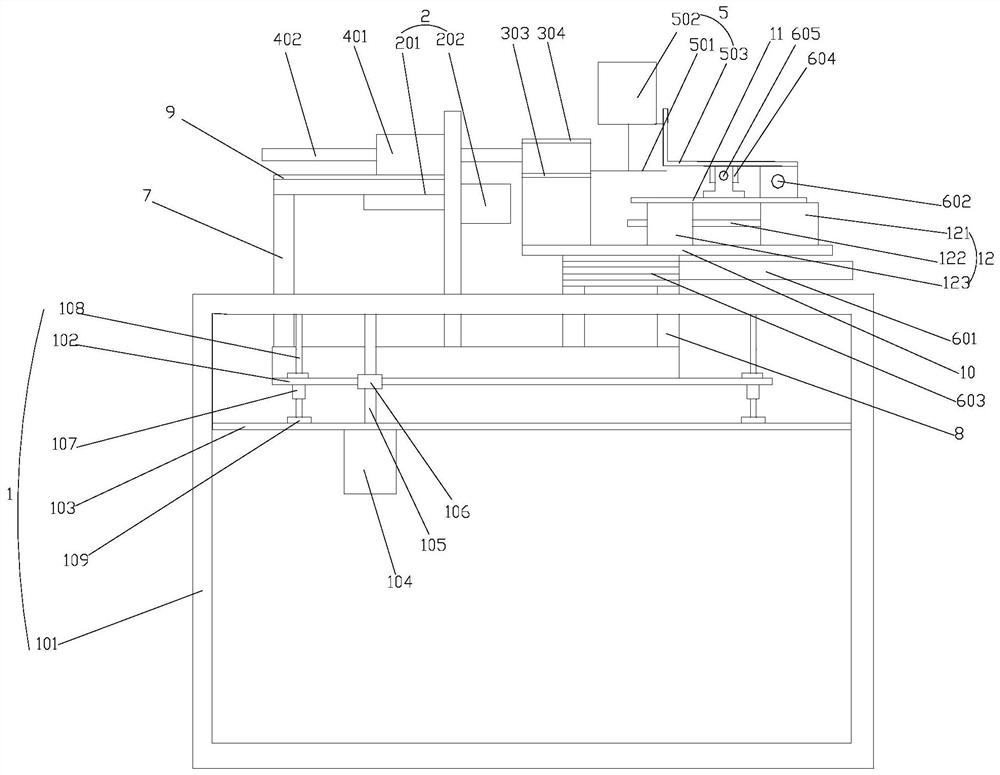

Processing device for processing slaughtered and plucked poultry carcasses, comprising poultry-support devices and poultry-processing devices

ActiveCN105307959AConveyorsPoultry eviscerating devicesEngineeringElectrical and Electronics engineering

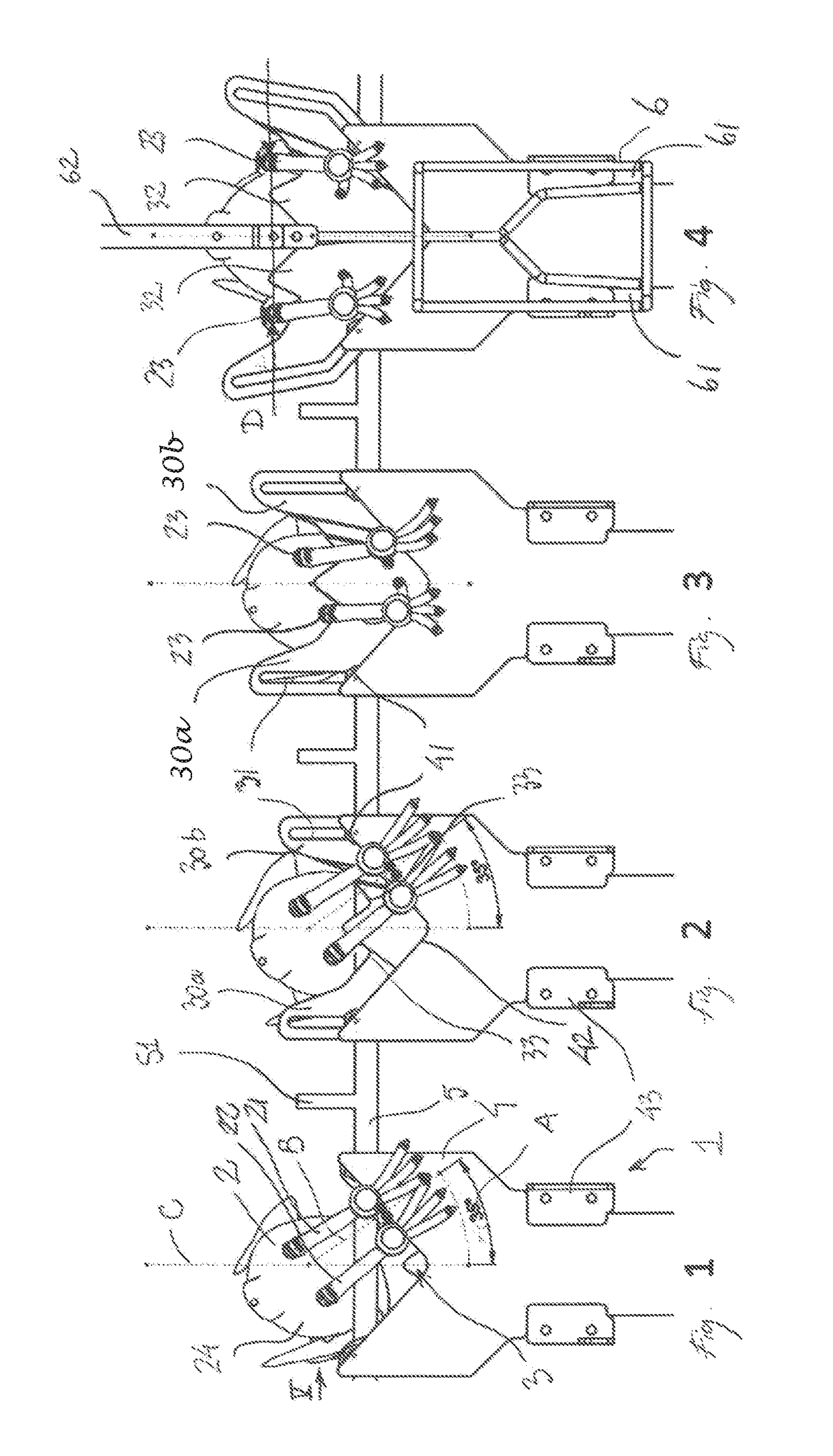

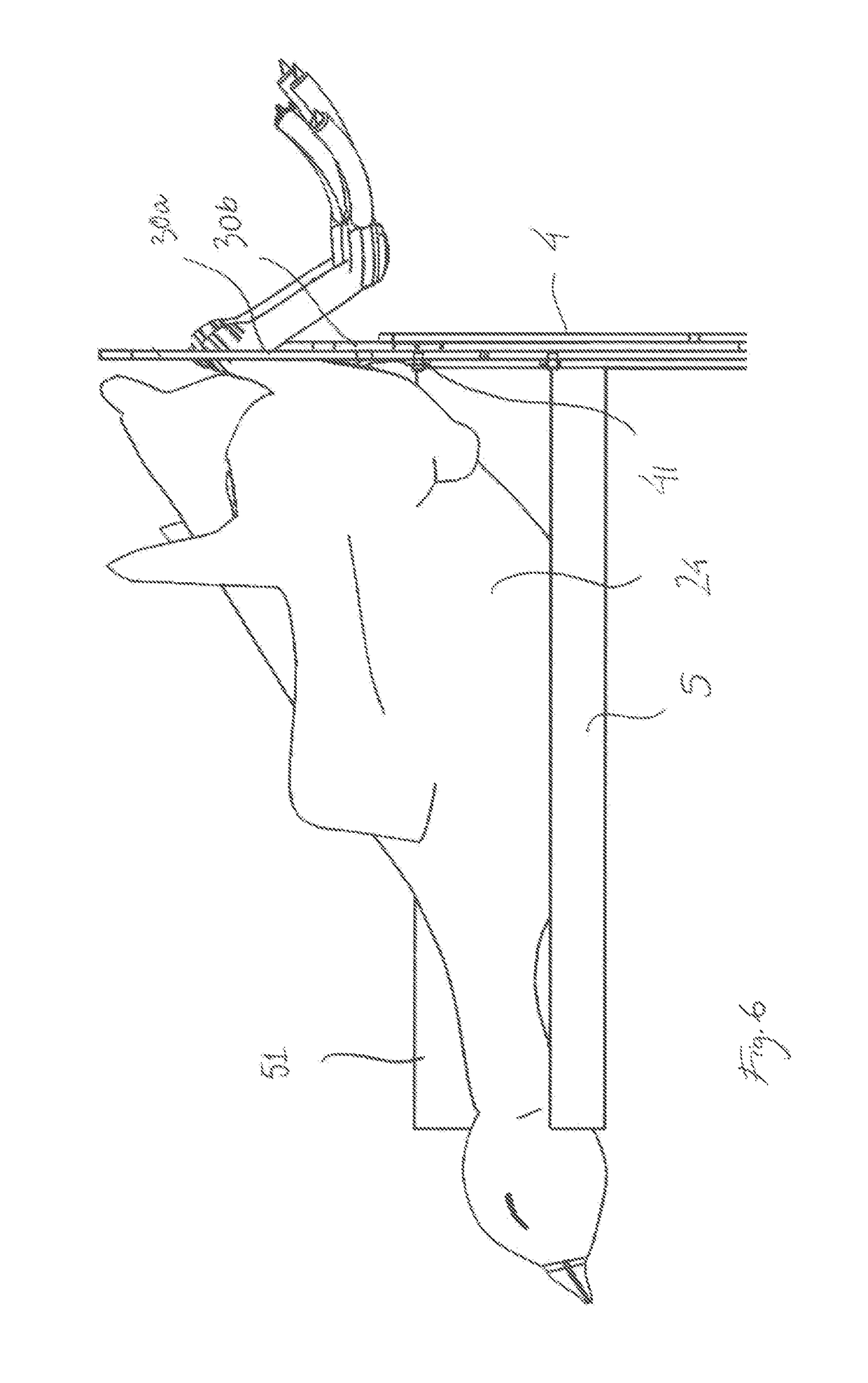

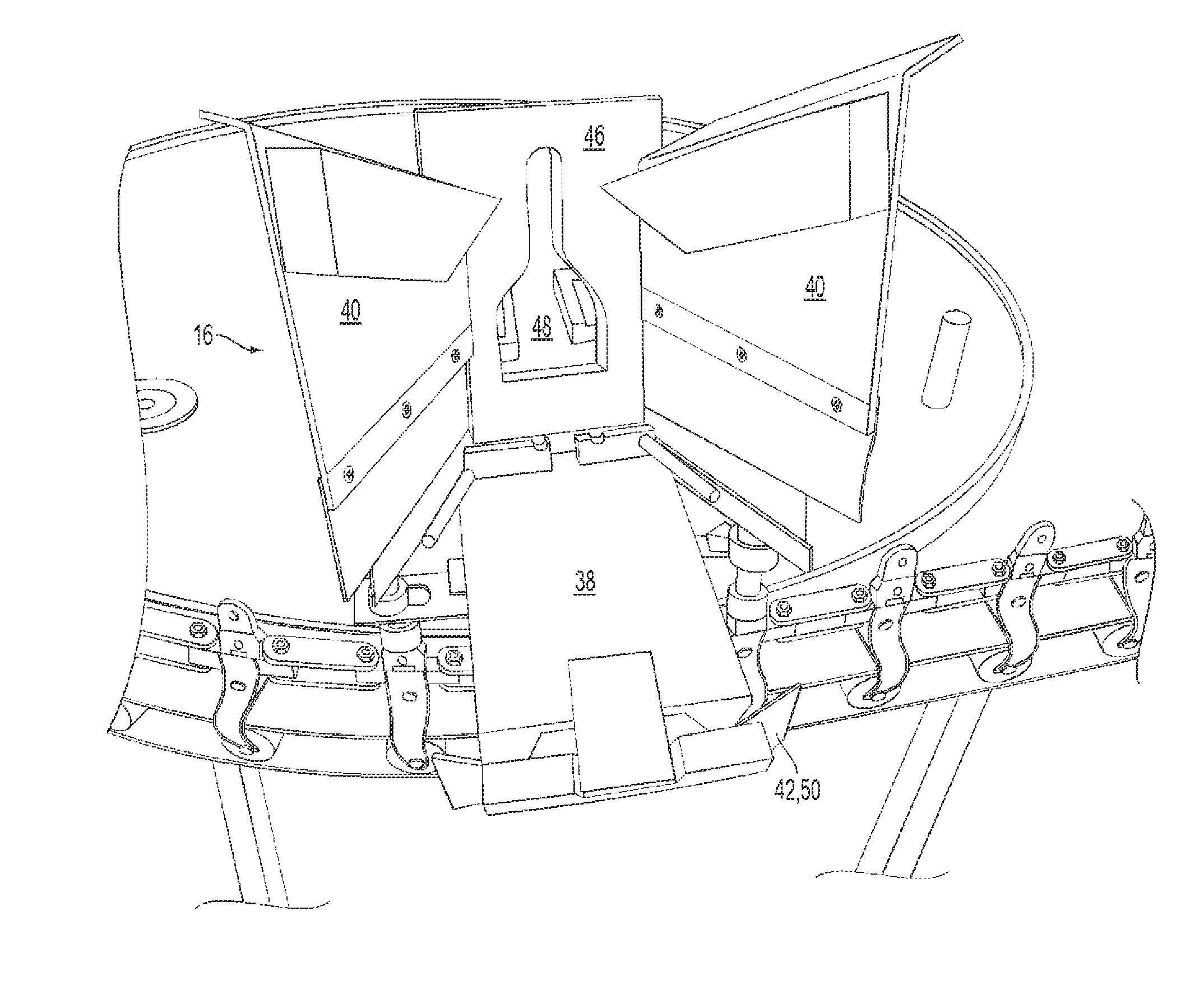

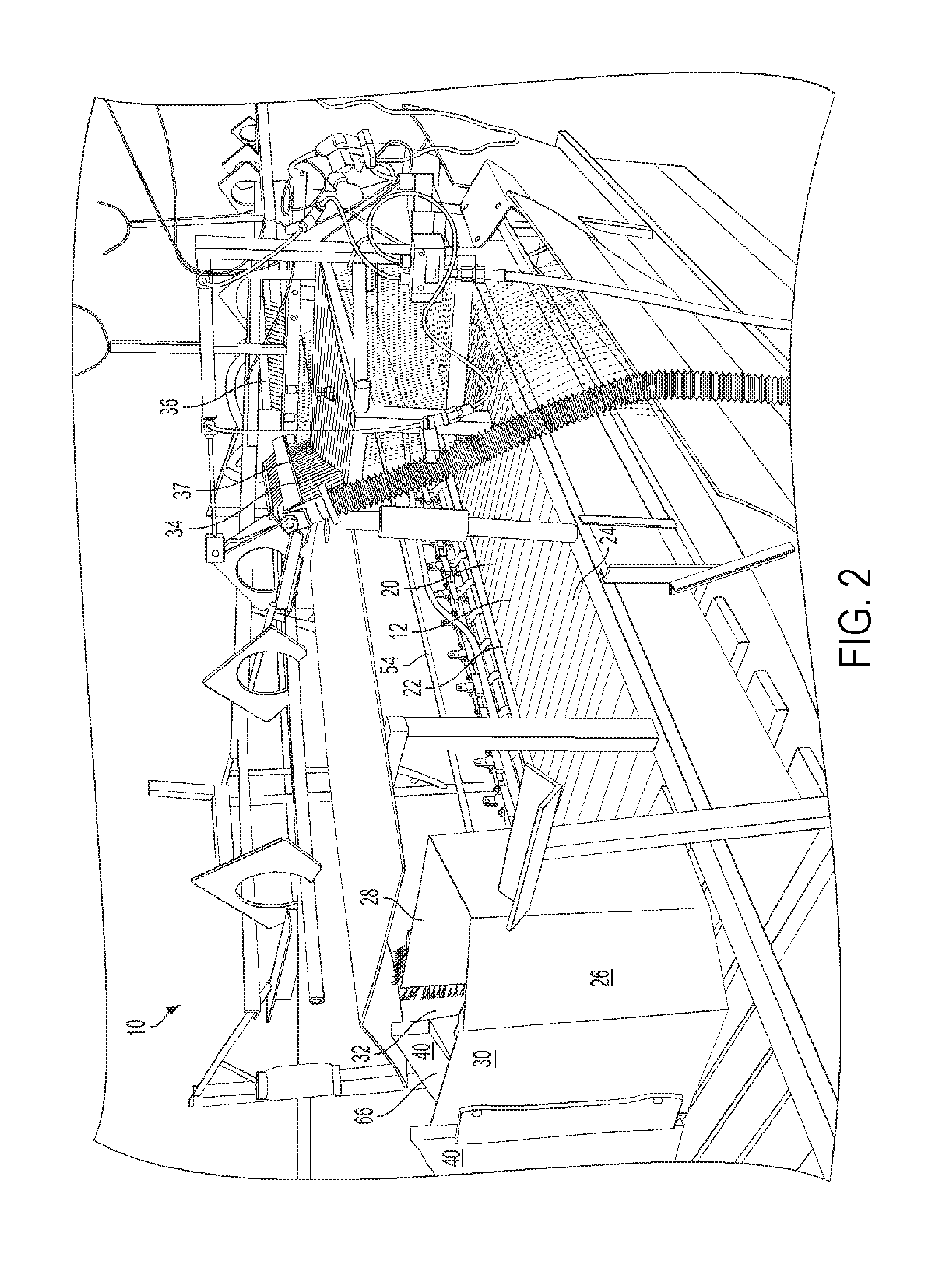

The invention relates to a processing device (210) for processing slaughtered and plucked poultry carcasses (152), having multiple processing devices (21) that are equipped to transport poultry carcasses (152) separately from a main conveying device (302) for processing purposes using a processing retaining means (820) which can be moved on a circumferential path. The processing device (210) has transfer stations (60; 51-66) which are arranged in a row along a main conveying line (20) in which the poultry carcasses (152) are conveyed in a suspended manner using support devices (402). Each processing device (21) is paired with a transfer station (60; 61-66) formed by a transfer pair (601) which has two rotational transferring devices (602, 652). The first rotational transferring device (602) removes poultry carcasses (152) from the support devices (402) and transfers the poultry carcasses to the processing retaining means (820) of the processing device (21). The second rotational transferring device (652) removes the processed poultry carcasses (152) from the processing retaining means (820) and transfers the poultry carcasses to the support devices (402). Each support device (402) has a pair (401) of supports (41, 42) with receiving portions (40.1, 40.2) for limbs (11, 12) of the poultry carcasses (152) and comprises a support controller (410). Each support (41, 42) is equipped with a controllable retaining device (403; 405) which is connected to the support controller (410) via a control element (444, 454) that controls a retaining part of the limb receiving portion (40.1, 40.2). In an open position of the controllable retaining part, the limb receiving portion (40.1, 40.2) is open so that the poultry carcass limbs (11, 12) are inserted and removed without being clamped, and the limb receiving portion contacts the poultry carcass limbs (11, 12) only in a closed position of the retaining part. The poultry processing device (21) has a processing controller to which the processing retaining means (820) is connected and by means which the processing retaining means can be moved into different positions along the retaining means circumferential path, namely a starting position for receiving the poultry carcasses, at least one processing position, and an end position for removing the poultry carcasses.

Owner:BAADER FOOD SYST DENMARK AS

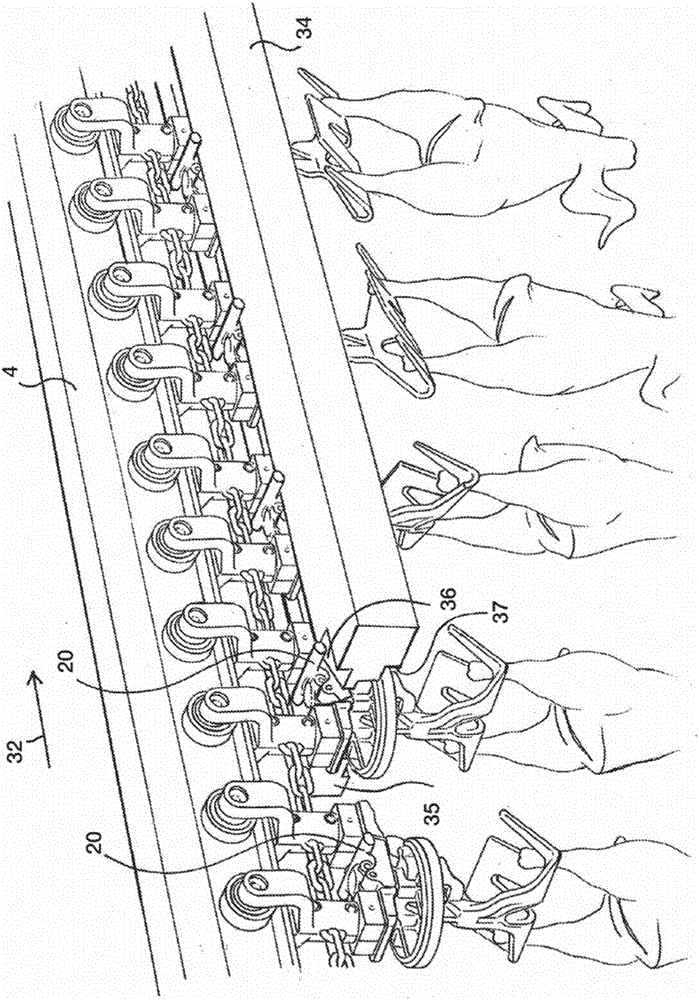

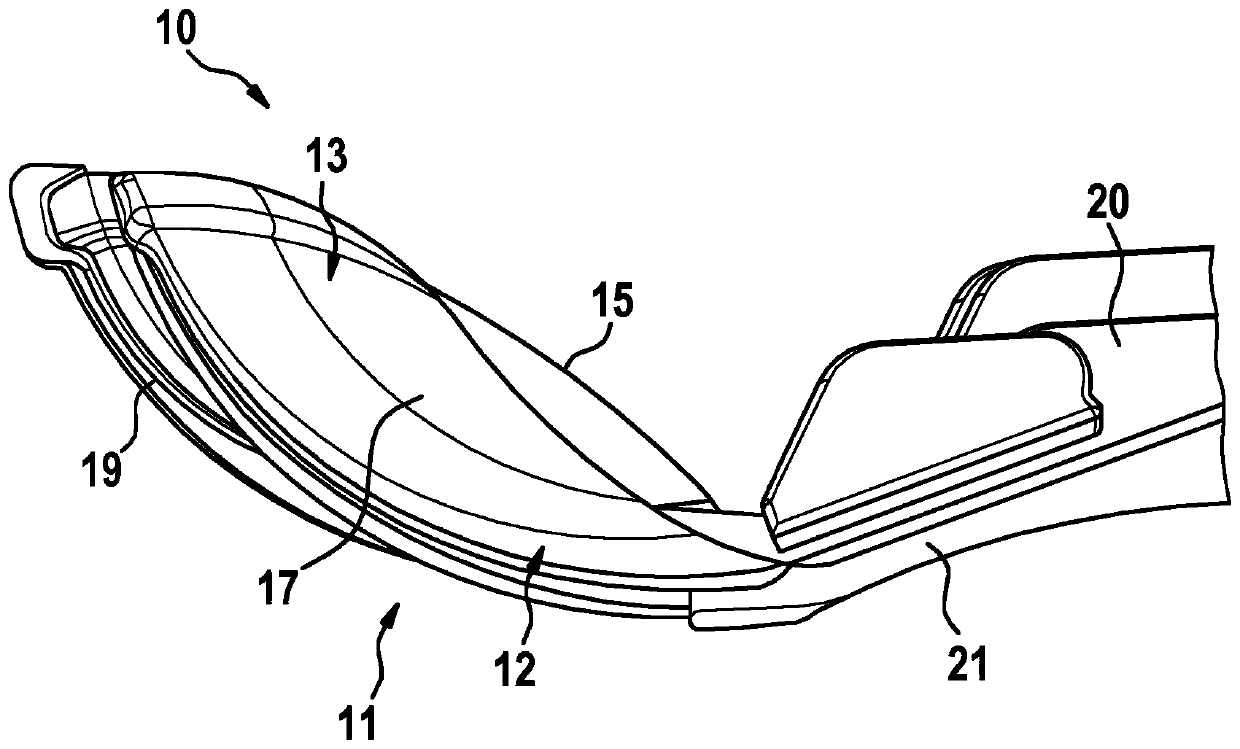

Device and method for changing the orientation of slaughter products

ActiveCN106163289AAvoid damageIncrease the lengthPoultry shacklesPoultry transferring/conveying devicesVertical planeEngineering

The invention provides a device for changing the orientation of slaughter products, comprising an endless guide (4) extending along a conveying path, product carriers (3) which are movable along the guide. Each carrier comprises a base part (6) and a rotary part (7) connected to the base part. The base part is provided with at least one runner (10) which cooperates with the guide during operation of the device. The rotary part is provided with an engagement part and with a suspension part connected to the engagement part for suspending a slaughter product from the suspension part. The rotary part is rotatable about an axis of rotation that extends in a vertical plane perpendicular to the conveying path. The device further comprises at least one operating element disposed beside the conveying path, which is configured to cooperate with the engagement part for causing the rotary part to rotate about the axis relative to the base part. The conveying path comprises an arcuate section (31) extending in a vertical plane, wherein the product carriers are present on the outer side of the arc. The operating element is disposed beside the arcuate section for causing the rotary parts of the product carriers to rotate at least in part about the associated axes of rotation during passage of the product carrier through the arcuate section, wherein the rotary part cannot pivot about a horizontal pivot axis that extends perpendicular to a vertical plane parallel to the arcuate section during passage of the associated product carrier through the arcuate section.

Owner:MAREL STORK POULTRY PROCESSING

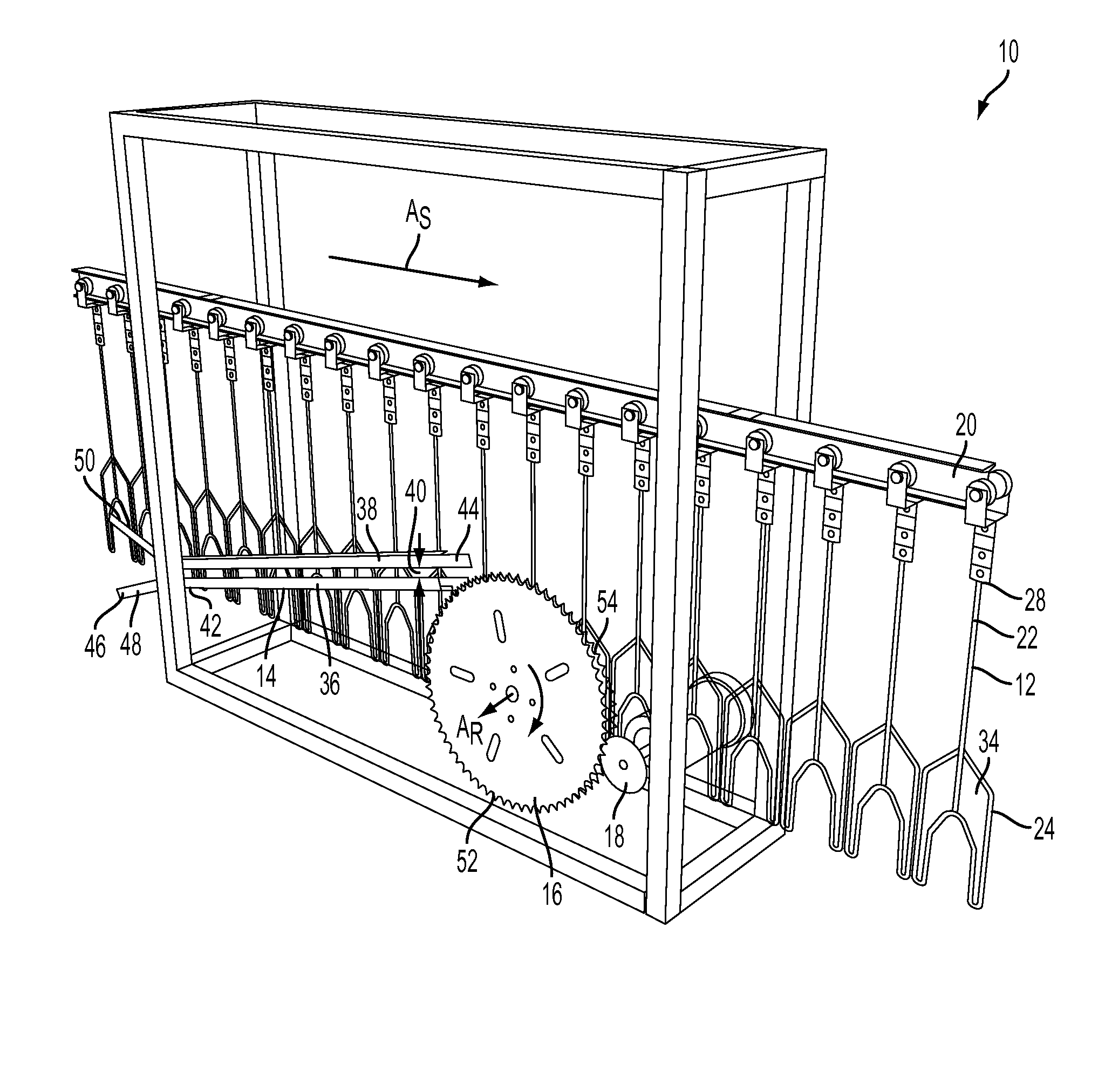

Passive Systems And Methods For Shackling Products

InactiveUS20110136422A1Simple processSimplified downstream subsystems to handle the birdsMeat processing plantsPoultry shacklesPoultry productEngineering

Owner:GEORGIA TECH RES CORP

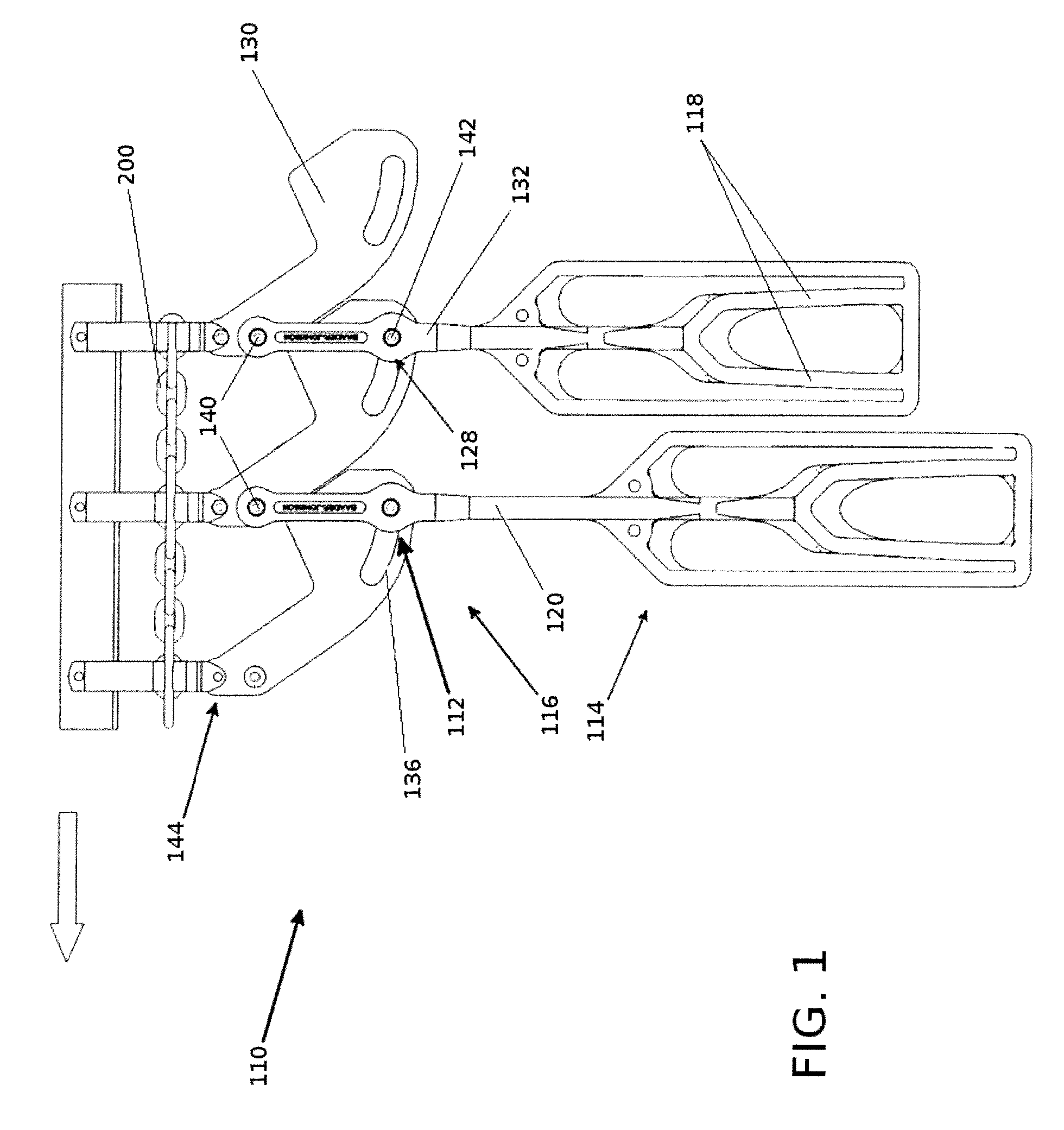

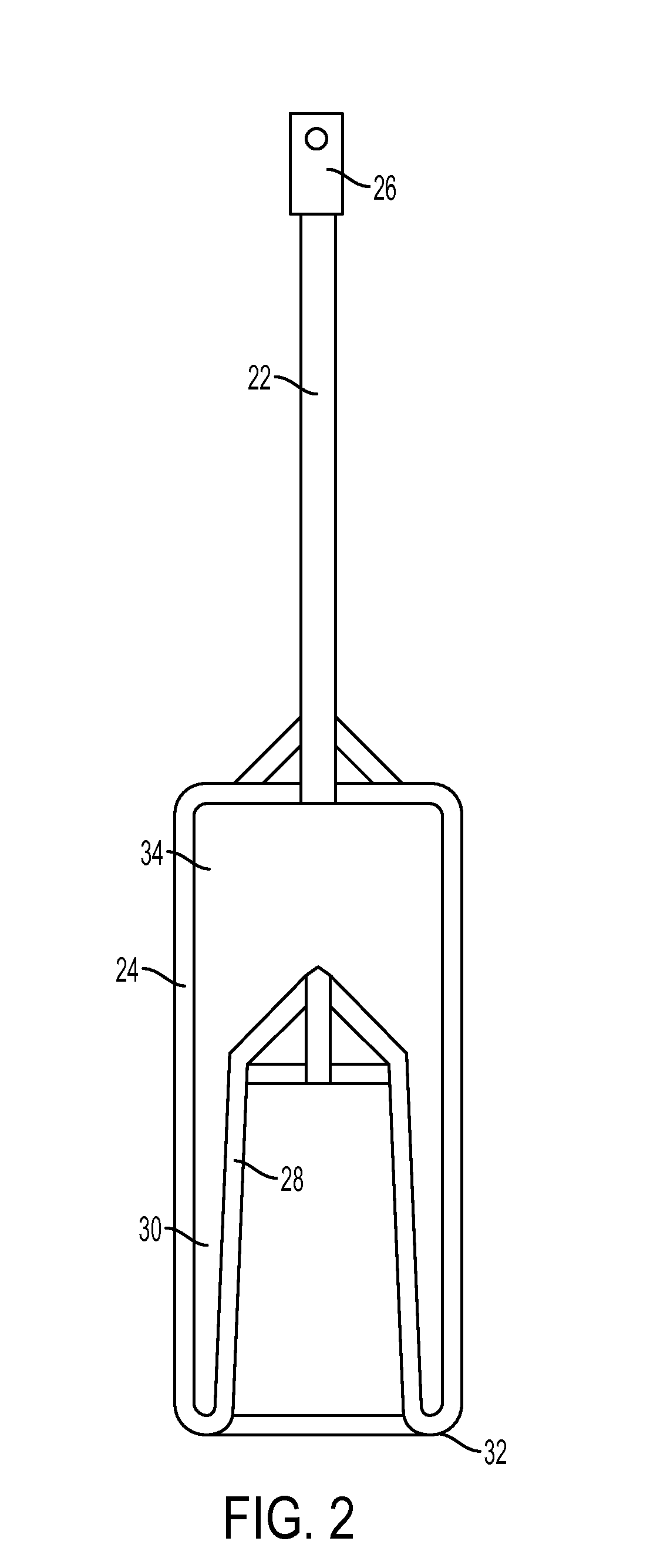

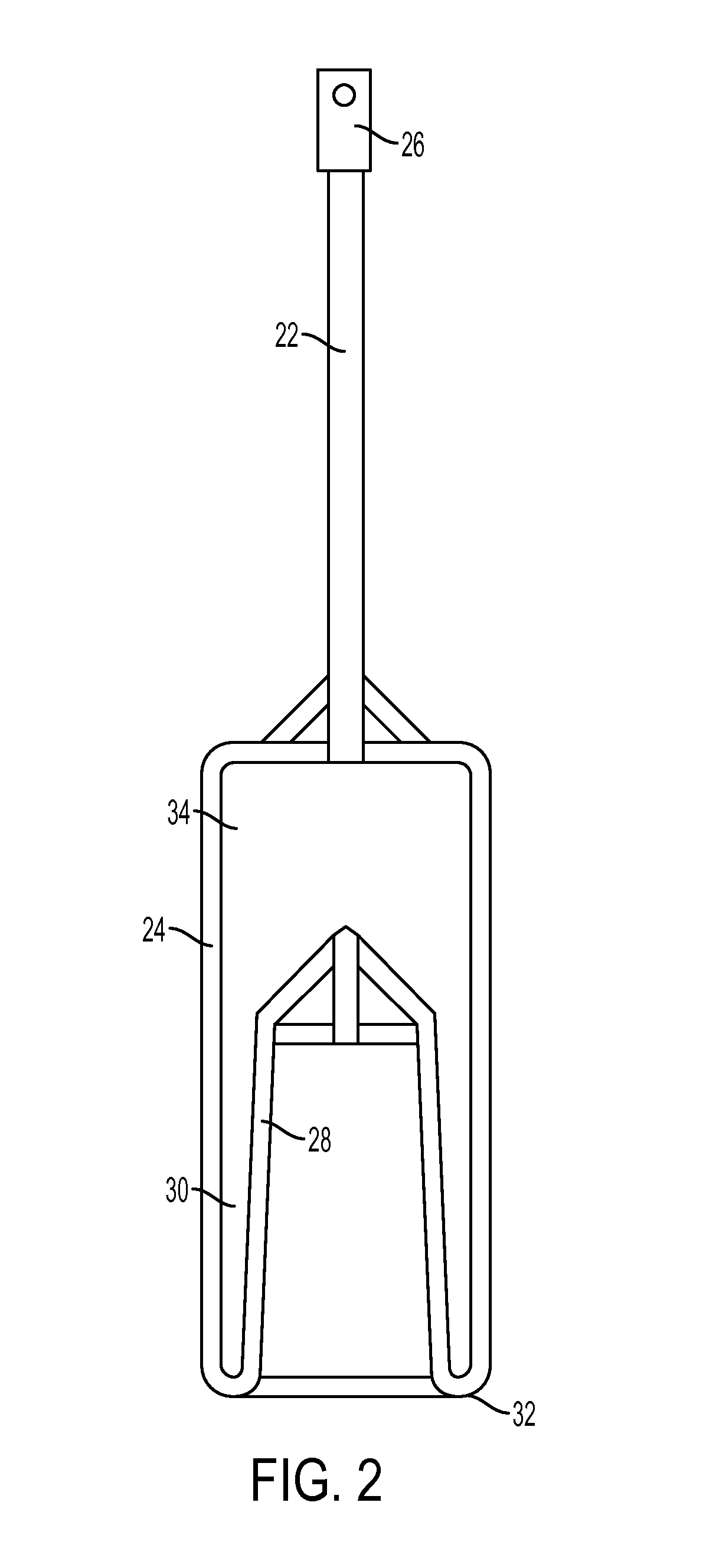

Breakaway poultry shackle

InactiveUS20070184768A1Increase downward forceSlaughtering animals fettering apparatusMeat processing plantsEngineeringShackle

A shackle for retaining and associating a carcass, such as, for example, a poultry carcass, with a conveyor system for transporting the carcass along a processing line. The shackle includes a disengagement, or breakaway, feature in which at least a portion of the shackle carrying the carcass automatically disengages from the conveyor system under a pre-established condition involving an increase in downward force, such as, for example, when the shackle becomes caught or otherwise impeded. The disengagement is accomplished by the opening, or separation, of bendable arms in response to the downward force created by the caught or impeded shackle, which creates or widens a gap between the arms that, in turn, causes the at least a portion of the shackle to be released. Once the shackle is disengaged, the conveyor can resume normal travel along the processing line, and processing operations can continue.

Owner:JOHNSON FOOD EQUIP

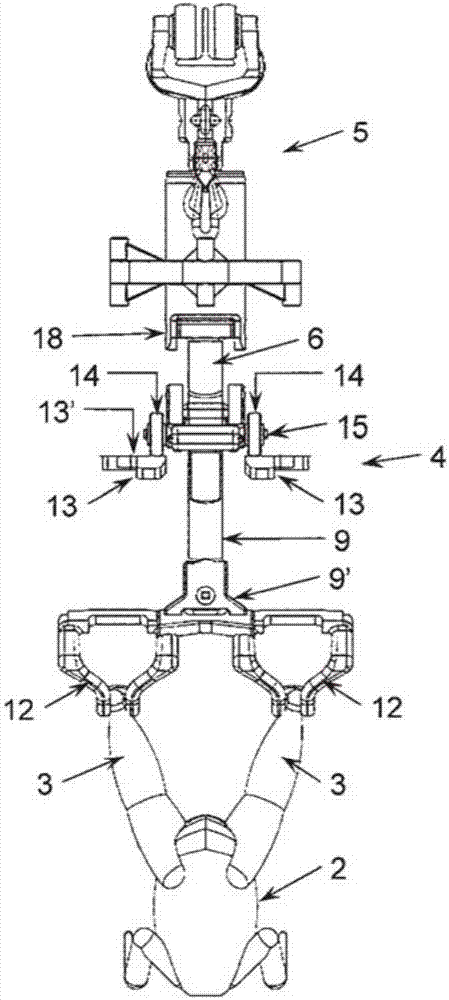

Conveyor line and carrier for poultry used in said conveyor line

ActiveCN106857772APoultry shacklesPoultry transferring/conveying devicesMechanical engineeringEngineering

Conveyor line and carrier comprising hooks for suspending poultry by the legs, and further comprising a carriage for moving the carrier with the suspended poultry along a track of the conveyor line, and arranged with at least a first rotatable vertical rod suspended from the carriage, which first rotatable rod is provided with a sideways extending arm for adjusting an orientation of the poultry or poultry parts with reference to the carriage, wherein near or at the sideways extending arm a frame is provided which is movable up and down with reference to the first vertical rod, wherein a second rod is suspended from said frame, and wherein said movability of the frame causes that the second rod is movable up and down whilst the first rod maintains its altitude, and wherein the hook or hooks for suspending the poultry are provided at a lower end of the second rod.

Owner:MEYN FOOD PROCESSING TECH BV

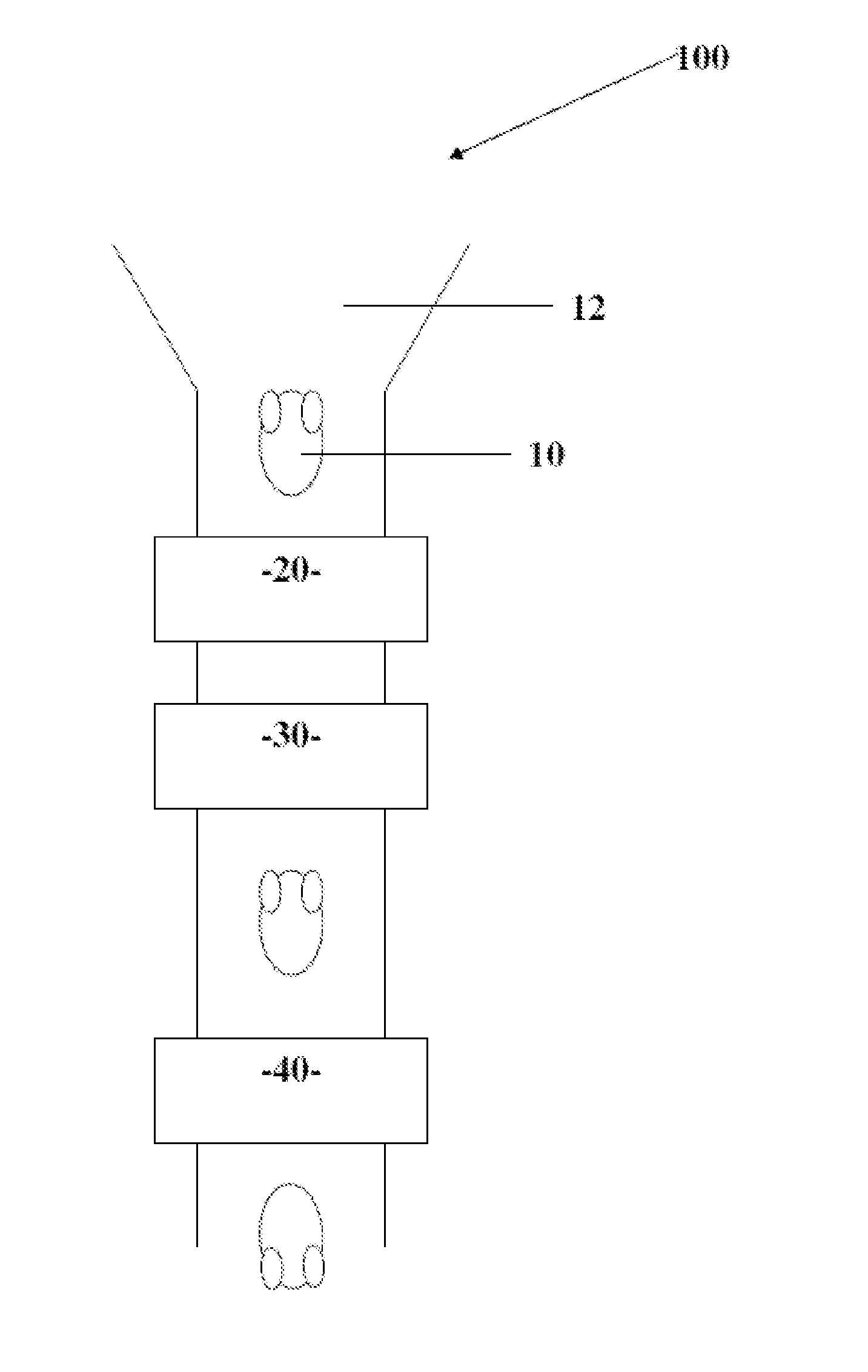

Passive systems and methods for shackling products

InactiveUS8328605B2Simple processSimplified downstream subsystems to handle the birdsMeat processing plantsPoultry shacklesPoultry productEngineering

Owner:GEORGIA TECH RES CORP

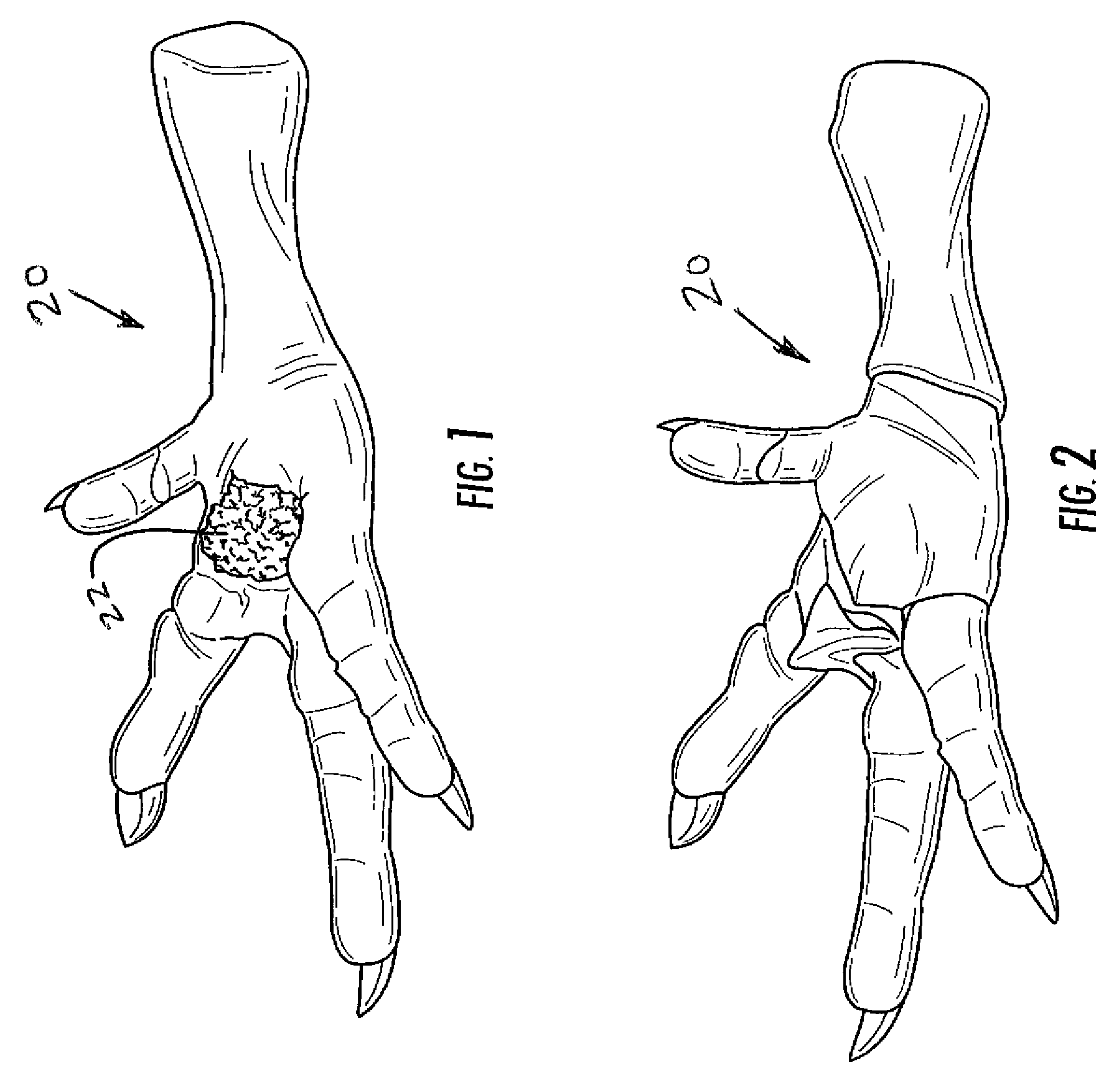

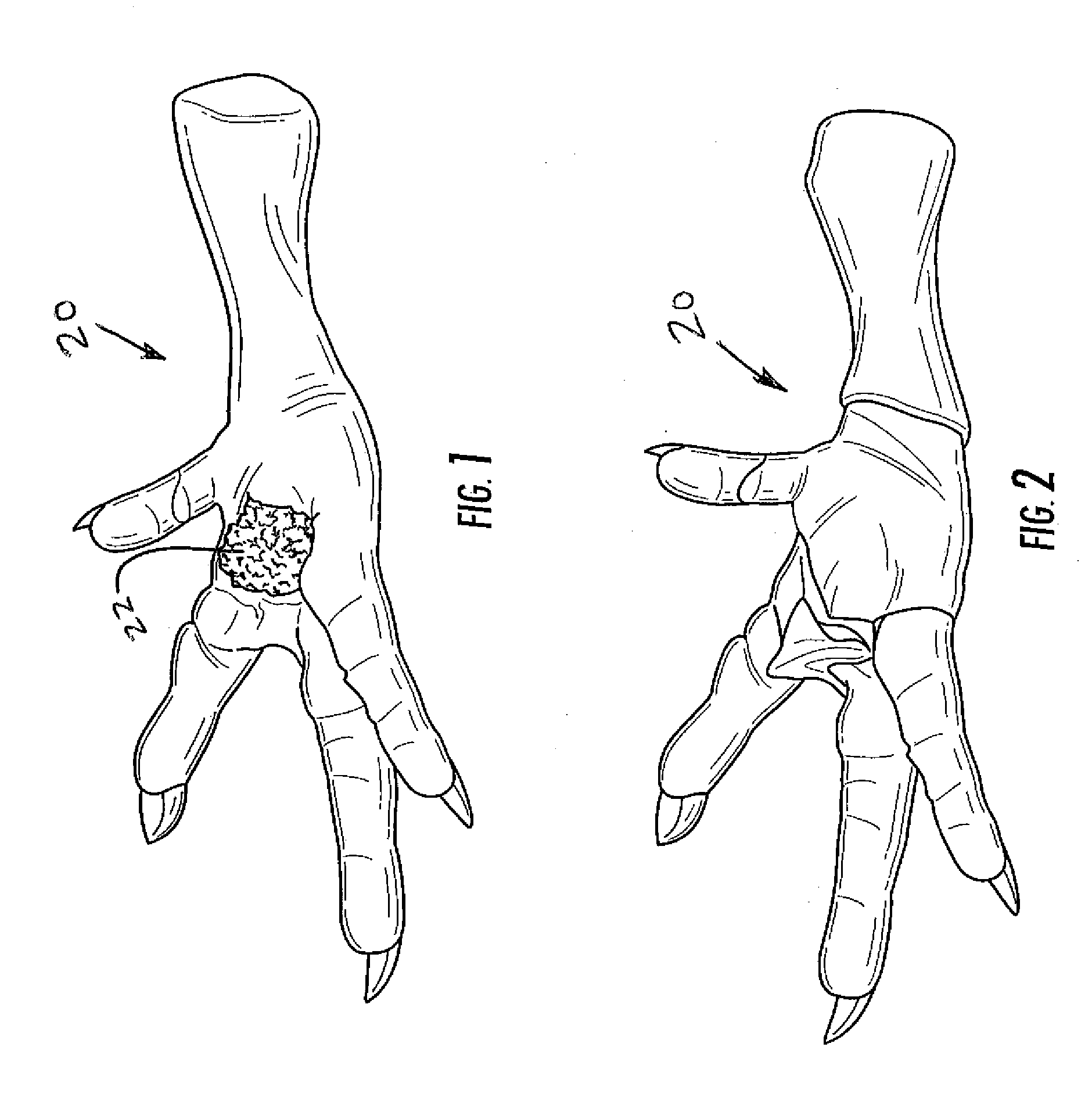

Device for removing material from feet of poultry

ActiveUS8827775B2Fish washing/descalingPoultry cleaning/disinfectionEngineeringMechanical engineering

A device is disclosed for removing lesion material from poultry feet including a frame defining an input zone, a cleaning zone, and an output zone. A conveyor moves poultry feet sequentially through the input zone, the cleaning zone, and the output zone, the conveyor configured for holding the poultry feet in a cleaning position. At least one spray head is located in the cleaning zone for spraying the poultry feet while held by the conveyor in the cleaning position to remove the lesion material.

Owner:JEFFERSON SR WAYNE ALLEN

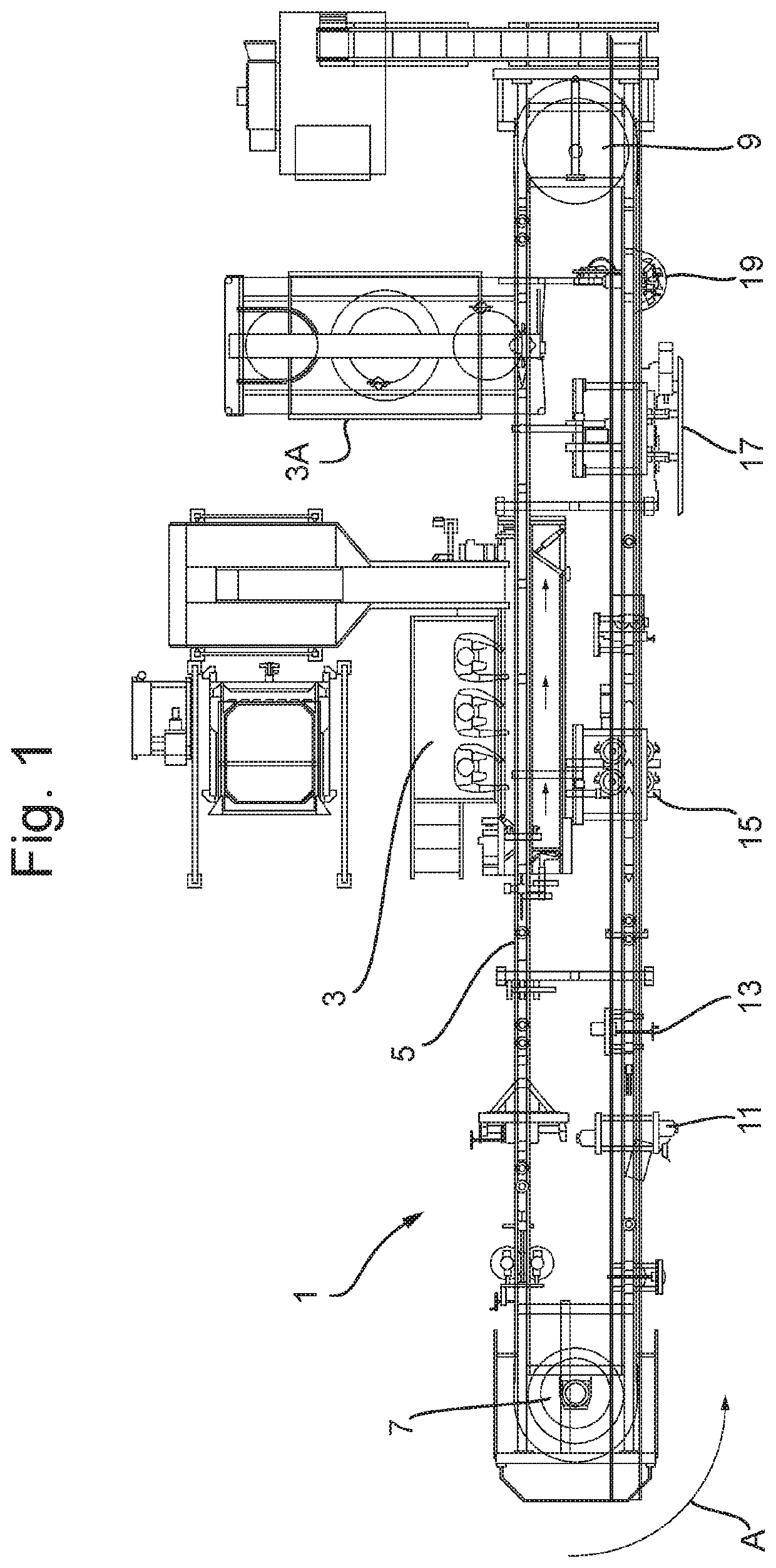

Method and apparatus for continuously harvesting surrounding meat from a successive plurality animal legs

ActiveUS20190387757A1Less cumbersome in assemblyCumbersome operationPoultry deboningPoultry shacklesEngineeringSacroiliac joint

A method of, and an apparatus (1) for, continuously harvesting surrounding meat from a successive plurality animal legs having articulated first and second animal bones and an intermediate joint. The method continuously conveys the animal legs through a path of conveyance, and determines a location of the intermediate joint. Based on the determined location of the intermediate joint, adjusting a position of the intermediate joint and a cutting implement relative to one another, and performing cutting of tissue at a location commensurate with the location of the intermediate joint. The step of determining the location of the intermediate joint is performed contactless, and without interrupting continuous conveyance of the animal legs.

Owner:FOODMATE

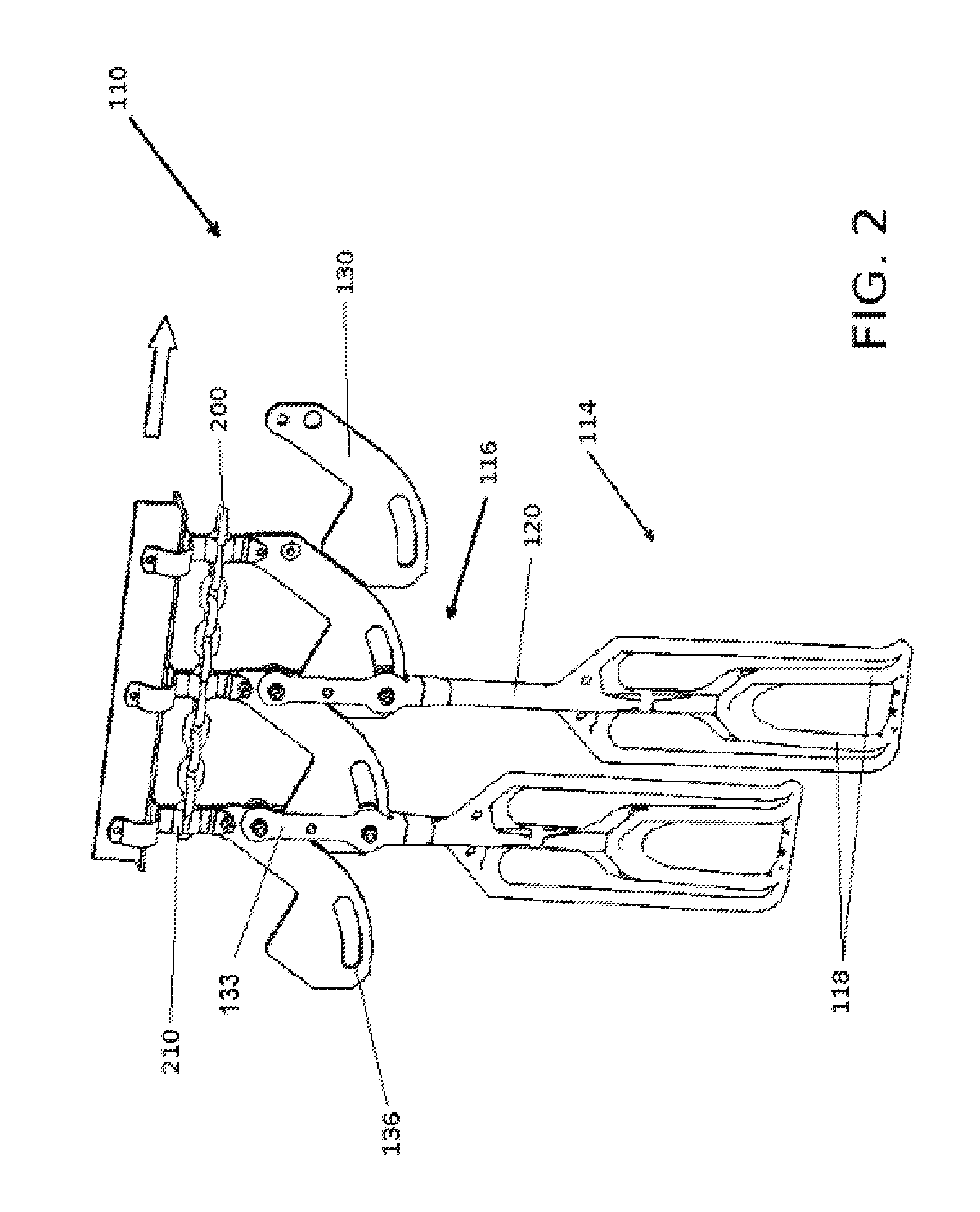

Shackle with pivot feature and log chain drive mechanism

Owner:BAADER FOOD SYST USA INC

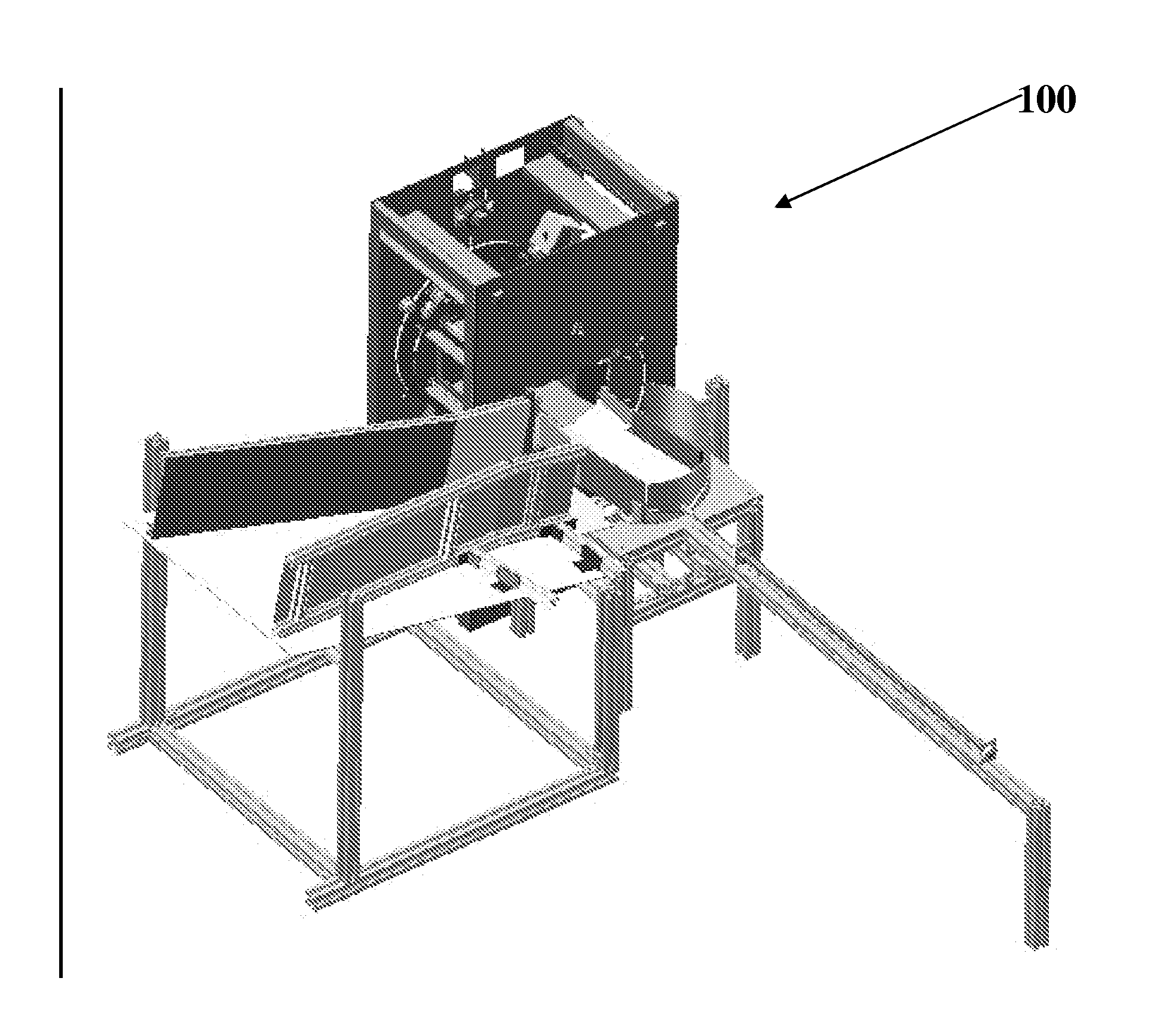

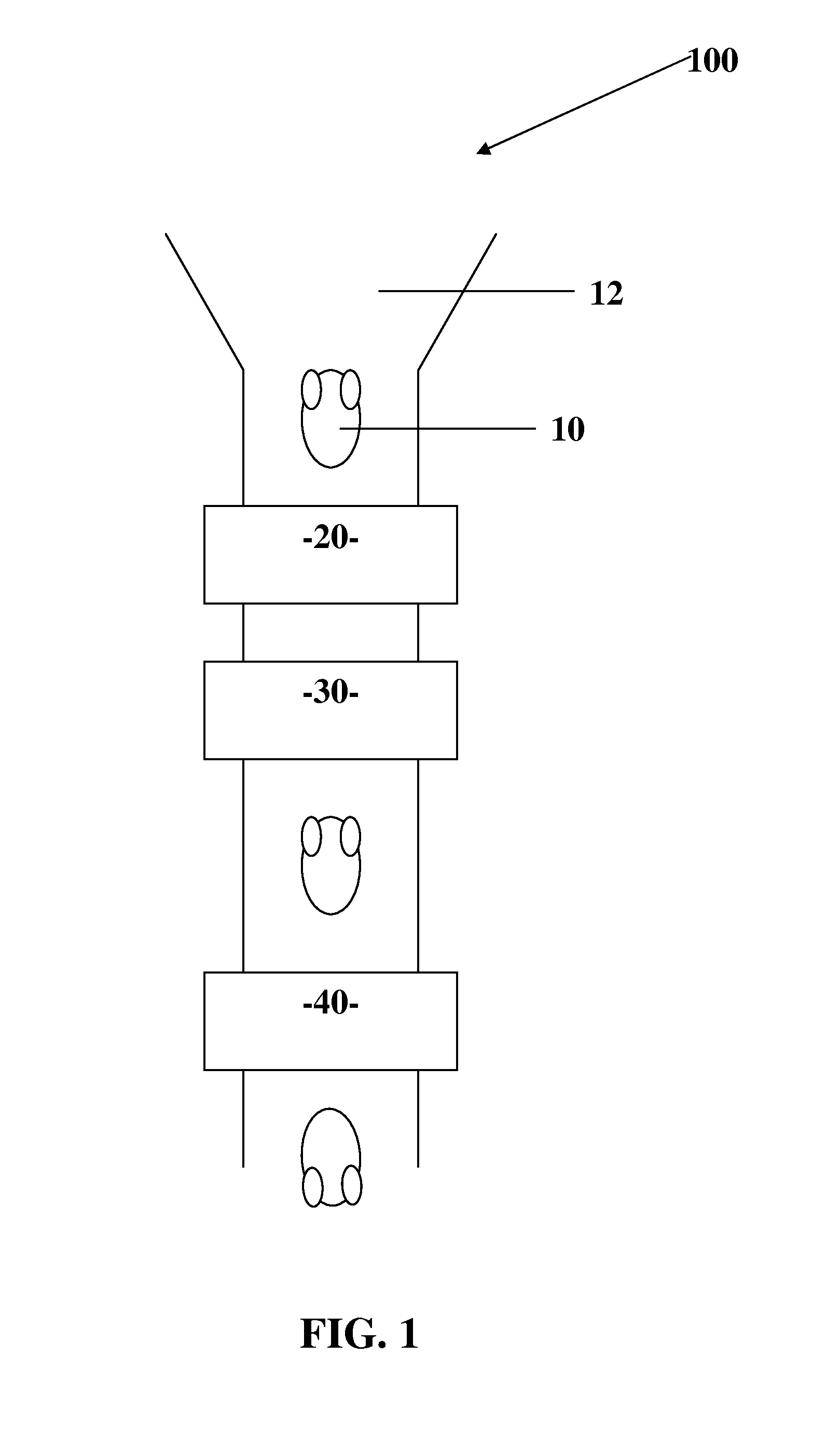

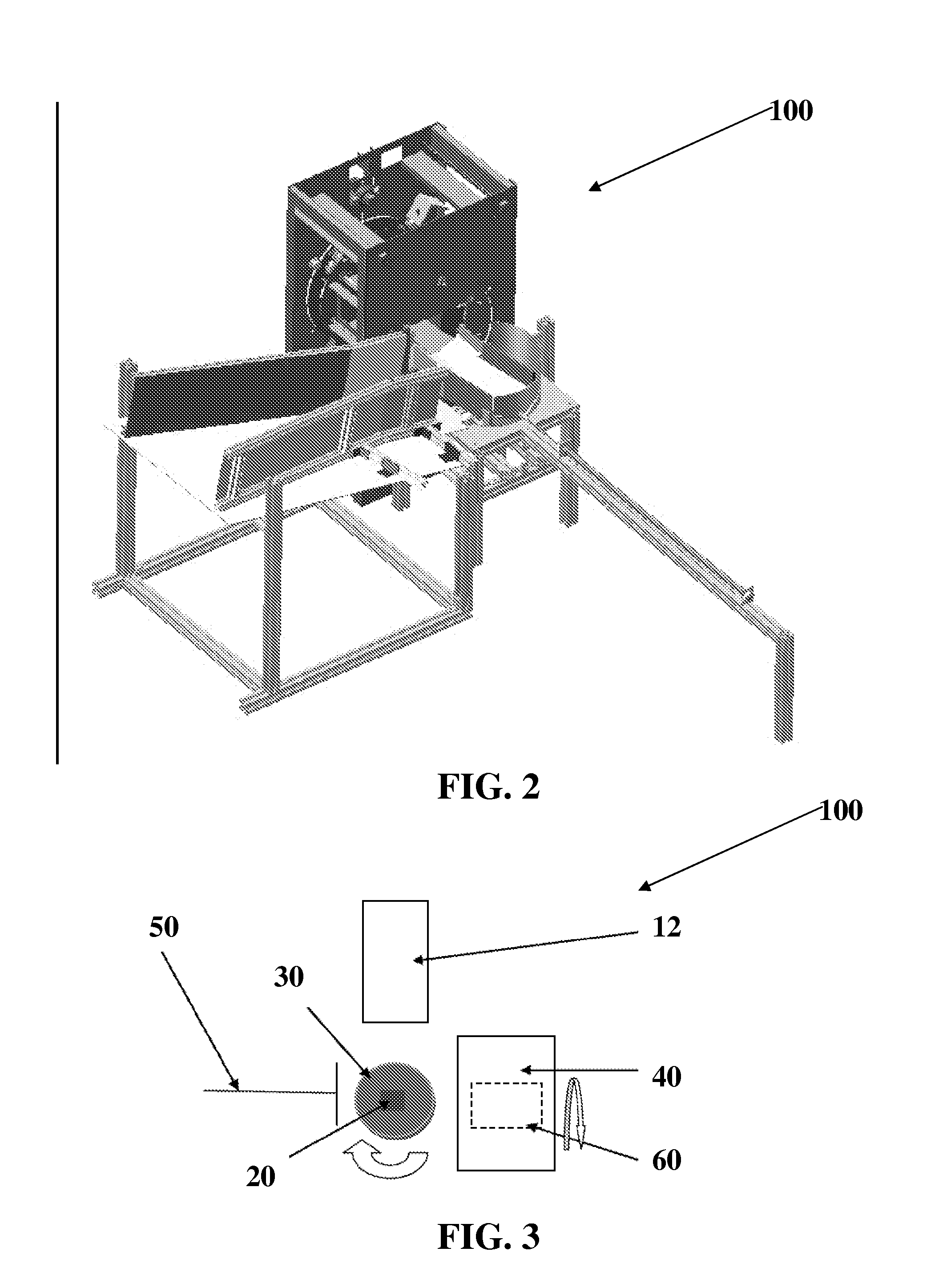

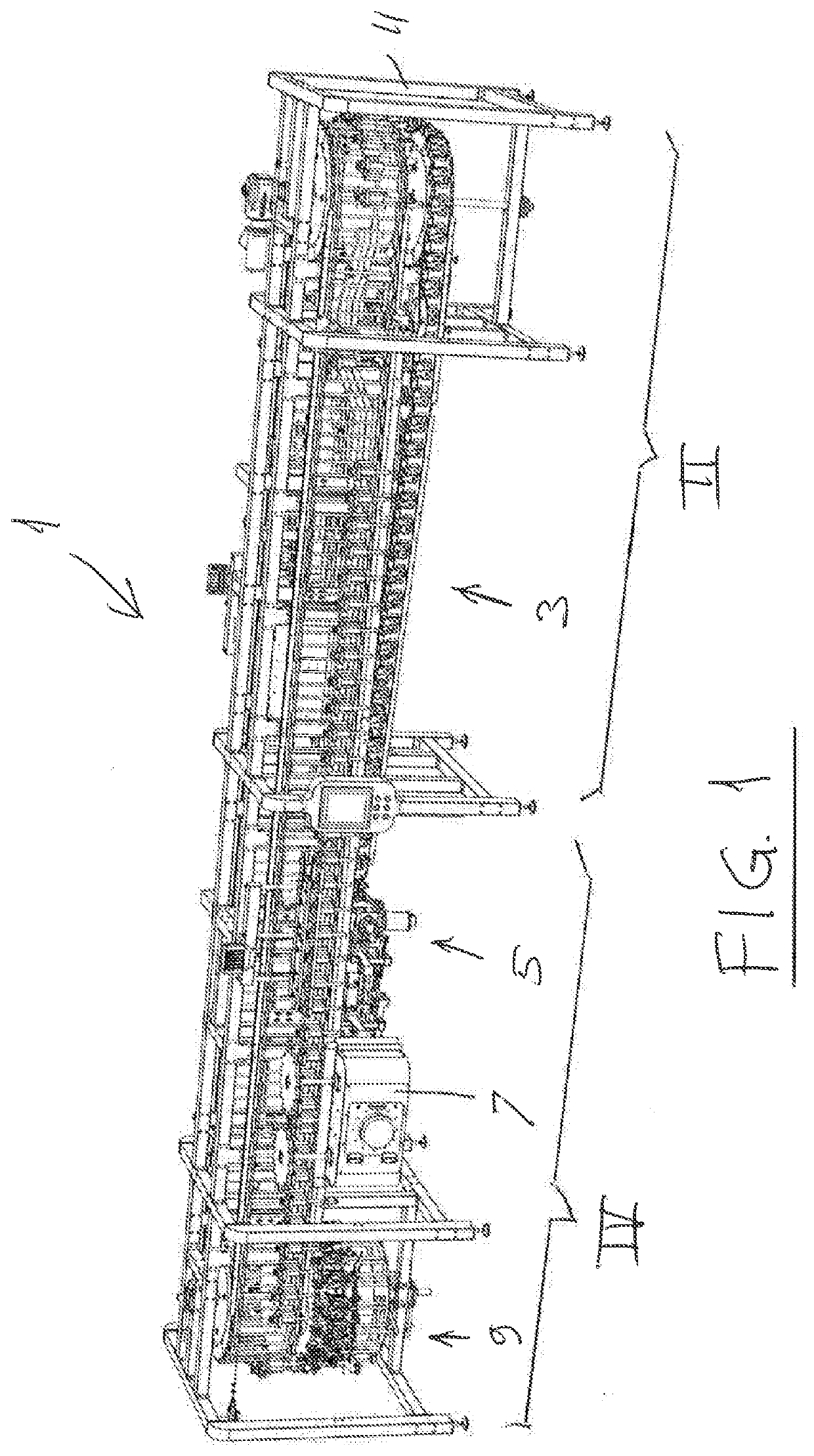

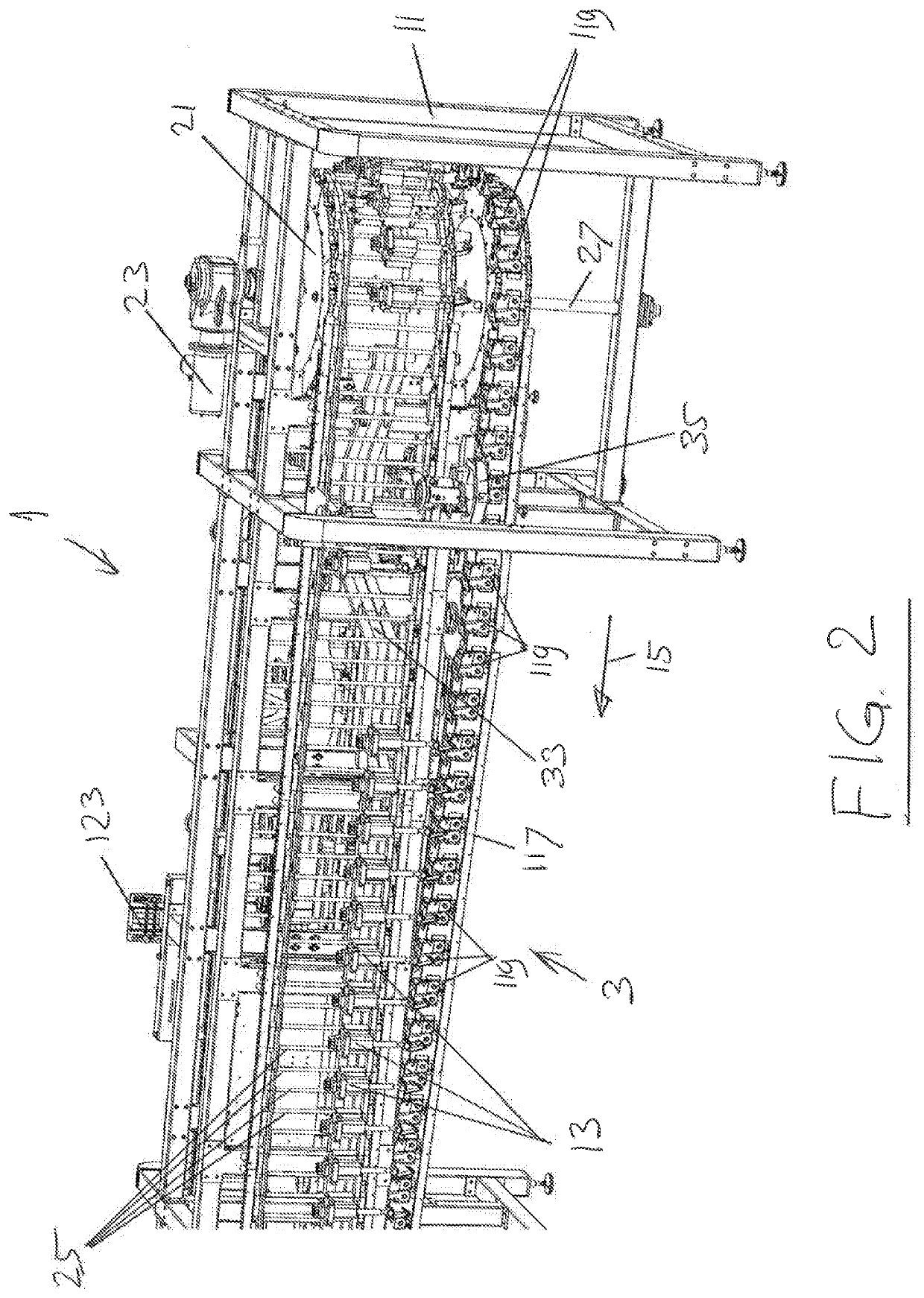

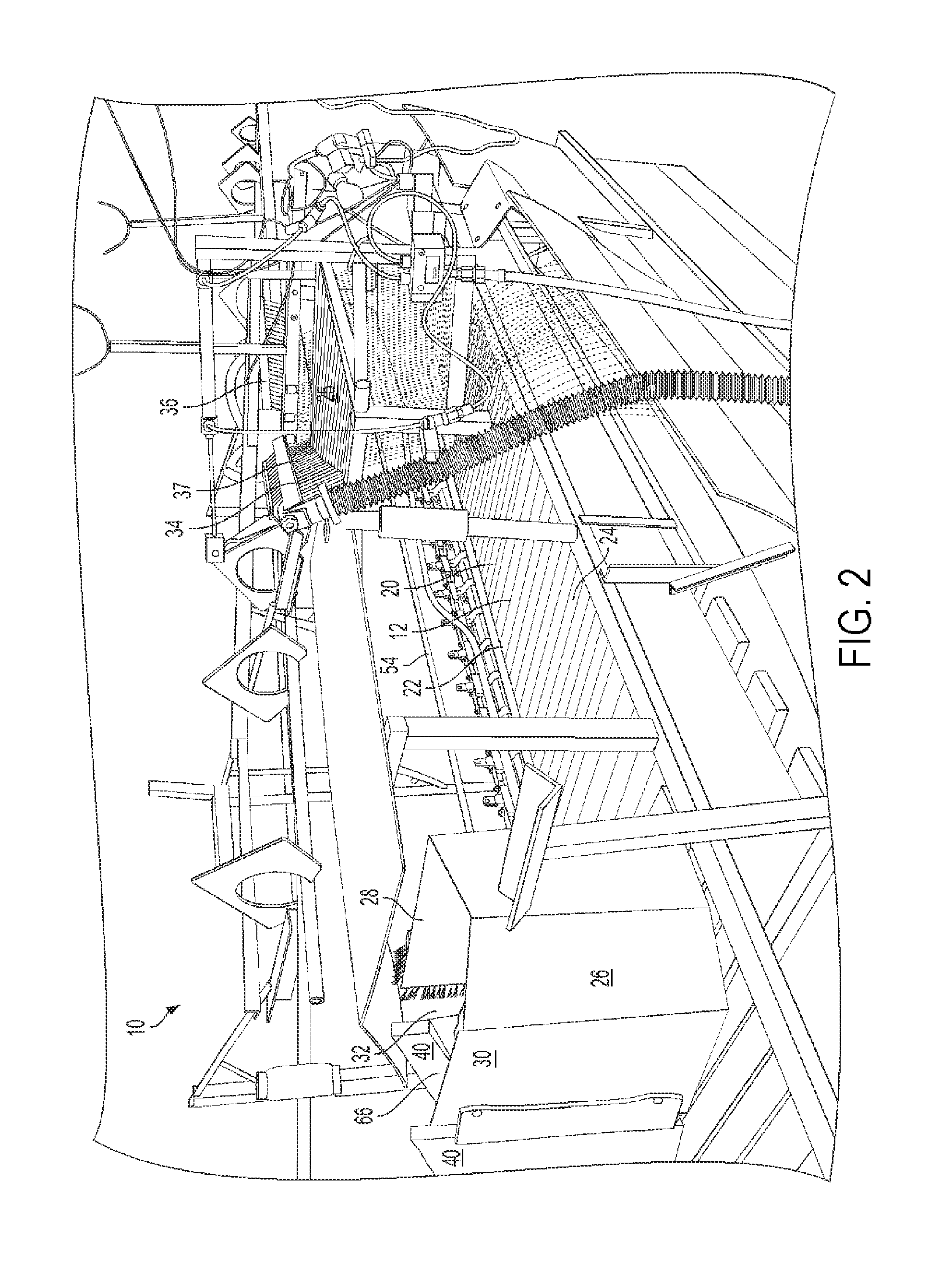

Automated Poultry Hanging System and Method

ActiveUS20130005230A1Minimize human interventionElectric current slaughtering/stunningMeat processing plantsControl systemEngineering

This invention relates to automated systems and methods for hanging live poultry for further processing. The system has an alignment conveyor, an alignment stunner, a hanging box, and a shackle. The alignment conveyor conveys poultry from an input point to the alignment stunner. The alignment stunner urges the poultry to move to a desired position on the alignment conveyor and stuns the poultry. The hanging box grasps the stunned poultry and places the poultry into the shackle for further processing. A computer and at least one sensor control operation of the system so that human intervention is minimized.

Owner:HARBEN III GROVER S

Gutting tool and gutting device having a gutting tool of this kind

ActiveCN110312428AWon't hurtRemove ensurePoultry eviscerating devicesPoultry shacklesEngineeringMechanical engineering

Owner:BAADER FOOD SYST DENMARK AS

Device for Removing Material from Feet of Poultry

ActiveUS20130109286A1Fish washing/descalingPoultry cleaning/disinfectionEngineeringMechanical engineering

A device is disclosed for removing lesion material from poultry feet including a frame defining an input zone, a cleaning zone, and an output zone. A conveyor moves poultry feet sequentially through the input zone, the cleaning zone, and the output zone, the conveyor configured for holding the poultry feet in a cleaning position. At least one spray head is located in the cleaning zone for spraying the poultry feet while held by the conveyor in the cleaning position to remove the lesion material.

Owner:JEFFERSON SR WAYNE ALLEN

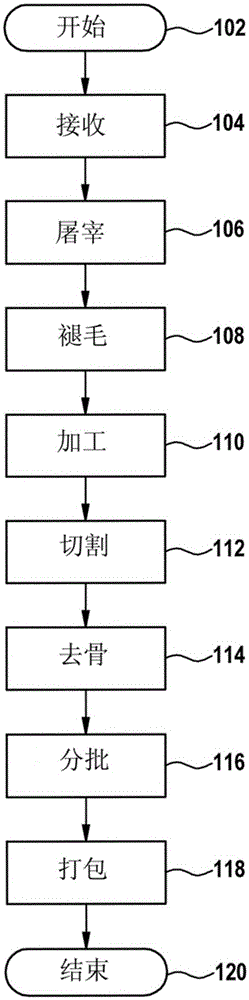

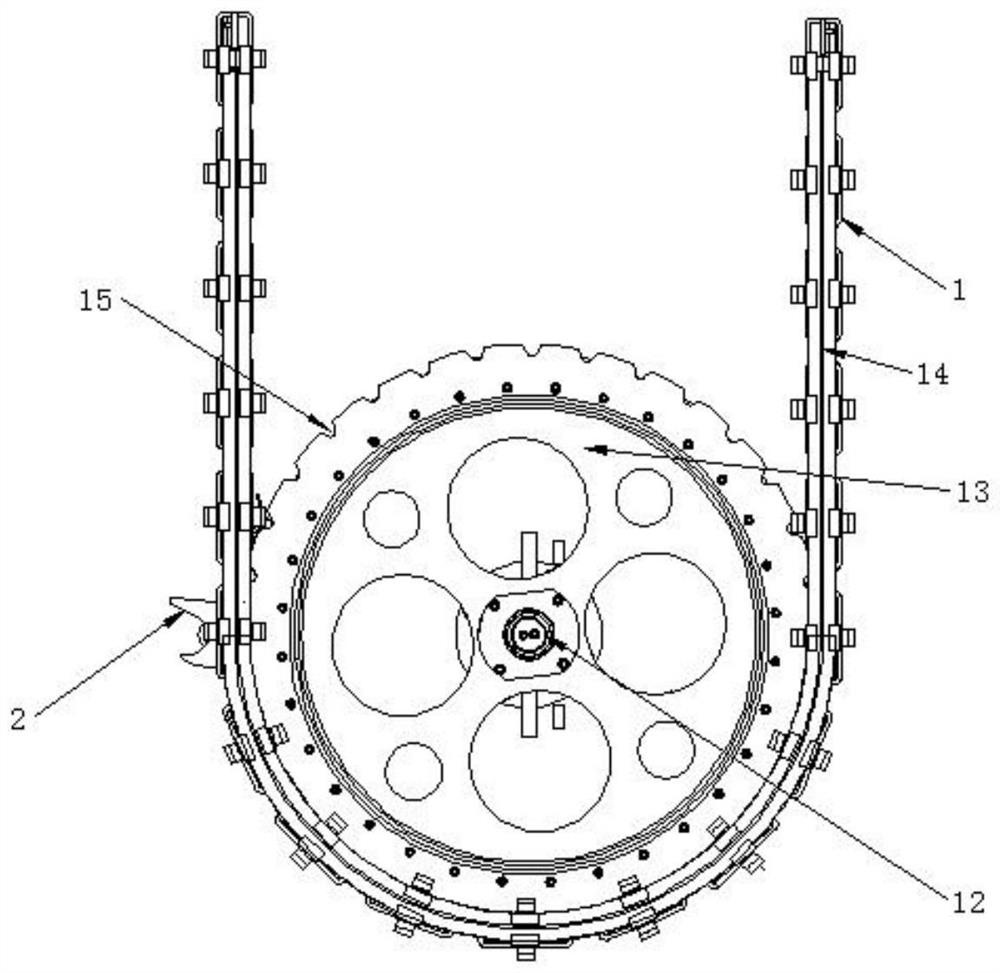

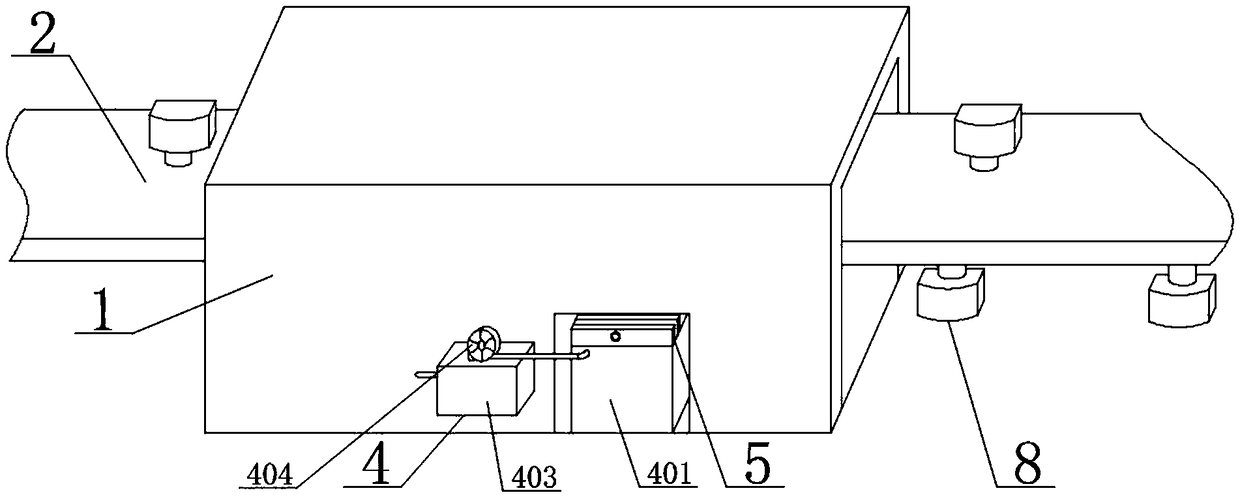

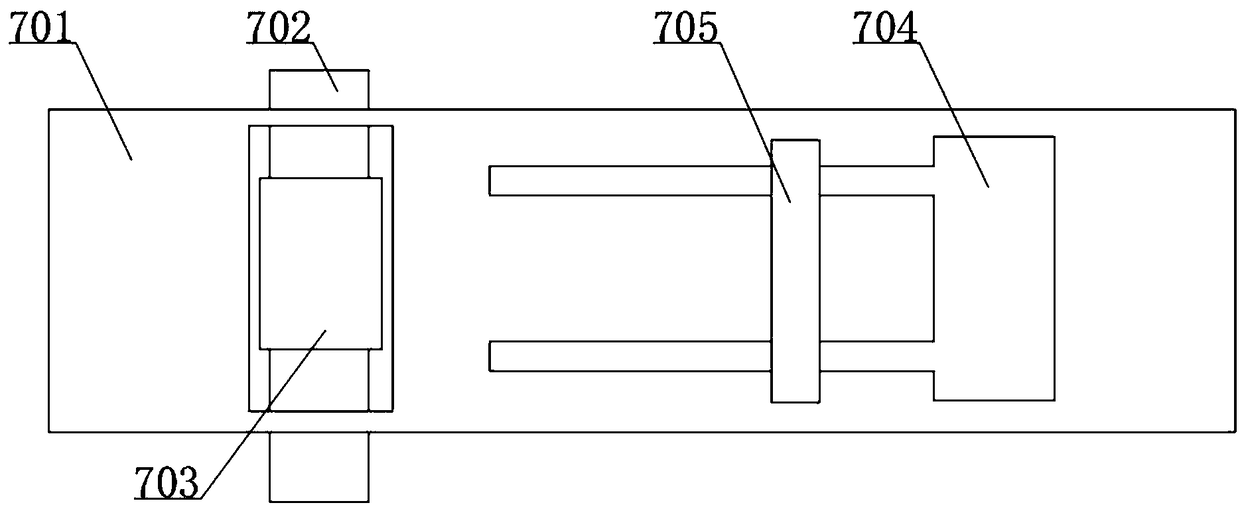

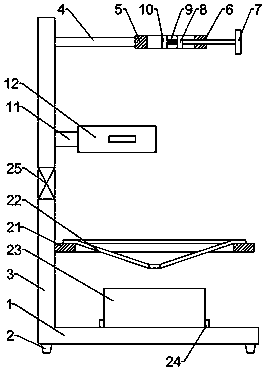

A chicken killing device suitable for a family

ActiveCN108887350AAvoid random splashesSolve the problem of easy accidental hand injuryPoultry plucking mechanismsPoultry/fish slaughtering/stunningDrive shaftKitchen utensils

The invention relates to a chicken killing device suitable for a family, belonging to the technical field of kitchen utensils. Comprising a first bottom plate and a second bottom plate, An outer frameis arranged between the edge of the first bottom plate and the edge of the second bottom plate, The second bottom plate is provided with a turntable, a second transmission shaft is arranged in the middle of the lower surface of the turntable, a support plate is arranged between the first bottom plate and the second bottom plate, a first transmission shaft is arranged between the support plate andthe outer frame, and the first transmission shaft is connected with the second transmission shaft to form an included angle of 90 degrees; 4 support bars are arrange on that rotary table, a barrel body is arranged on the 4 supporting bars, and a chicken head fix device is arranged on one of the supporting bars; The turntable is also provided with a chicken neck plucking and cutting device. The invention solves the problem that hands are easy to be injured by mistake when killing chickens, prevents chickens from being injured by knife and blood splashing easily during killing chickens, and finally solves the problem that chicken feathers are difficult to be plucked.

Owner:如东道博智能设备有限公司

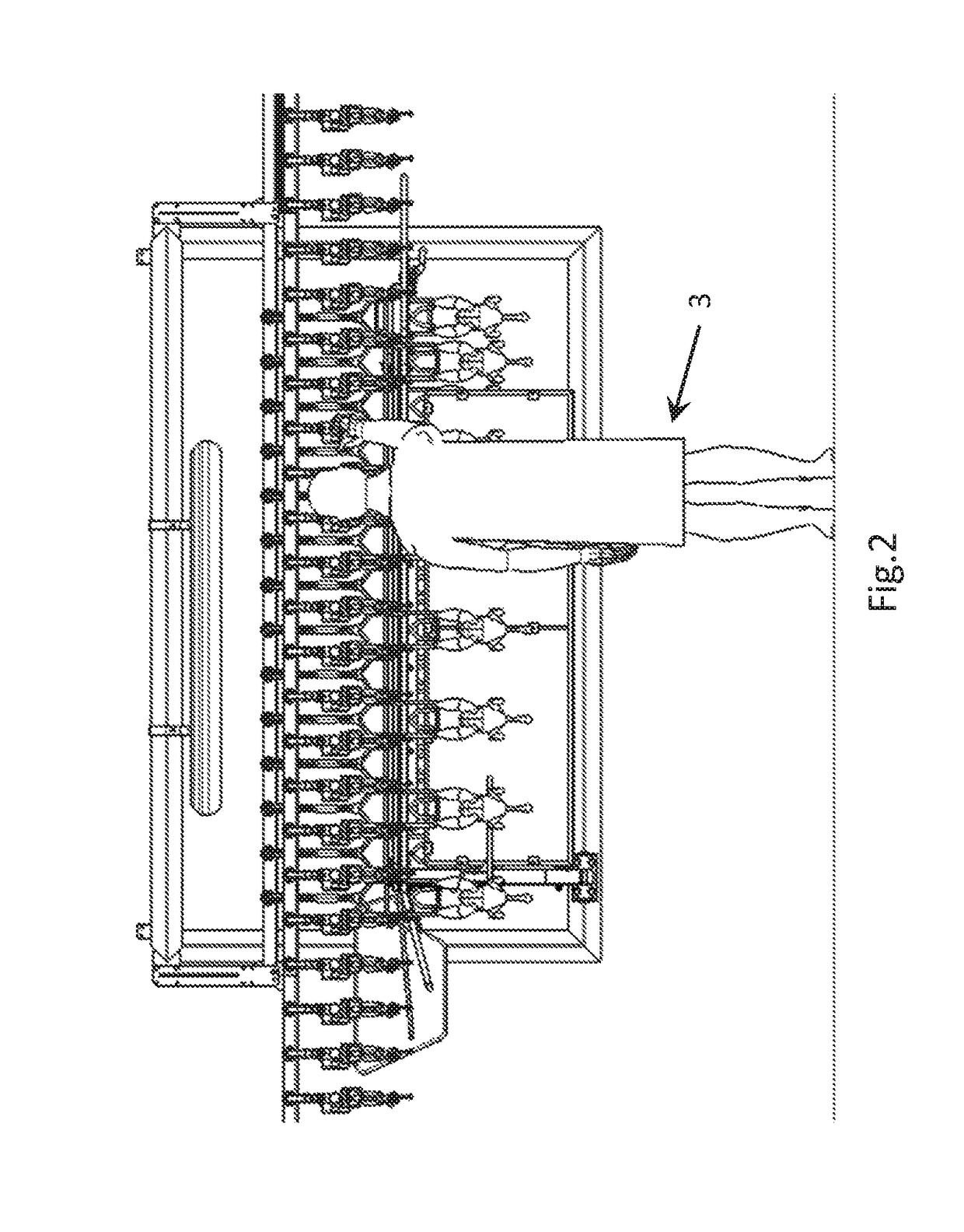

Livestock wing hair removing machine

PendingCN111670937AReduce occupancyOvercoming collision damage issuesPoultry plucking mechanismsPoultry shacklesAnimal scienceAgricultural science

The invention provides a livestock wing hair removing machine, and relates to the technical field of livestock wing hair removing tools. The livestock wing hair removing machine comprises a hanging device, a leading-in device, a positioning device, a wing opening device and a polishing device, wherein the wing opening device comprises wing opening blades which are arranged in a turnover manner andare used for opening duck wings. The livestock wing hair removing machine solves the problems that in the prior art, in the leading-in process of duck bodies, large shaking occurs, the duck wings cannot be accurately removed, the occupied space of a driving component is large, and assembly line processing cannot be realized.

Owner:寿光市和益自动化设备有限公司

Processing and/or inspection line for poultry suspended by the legs

ActiveUS20160278395A1Carcasses classification/gradingPoultry shacklesReciprocating motionEngineering

A processing line, inspection line, or both, includes a first conveyor line with shackles for suspending the poultry by the legs. The conveyor line is arranged to move the poultry in a conveying direction passed a processing and / or inspection station for the poultry, wherein at least along a part of the conveyor line an endless belt is provided that supports the shackles and moves the shackles sideways away from a first neutral vertical suspension position to a second position in which the shackles are suspended obliquely in the conveyor line so as to arrange that any back-and-forth movement of the shackles in their conveying direction is prevented or counteracted.

Owner:MEYN FOOD PROCESSING TECH BV

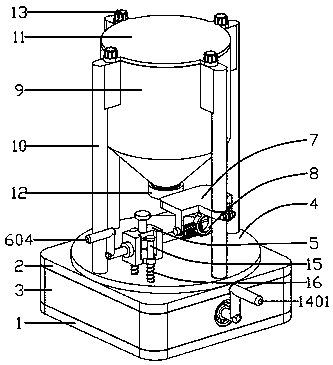

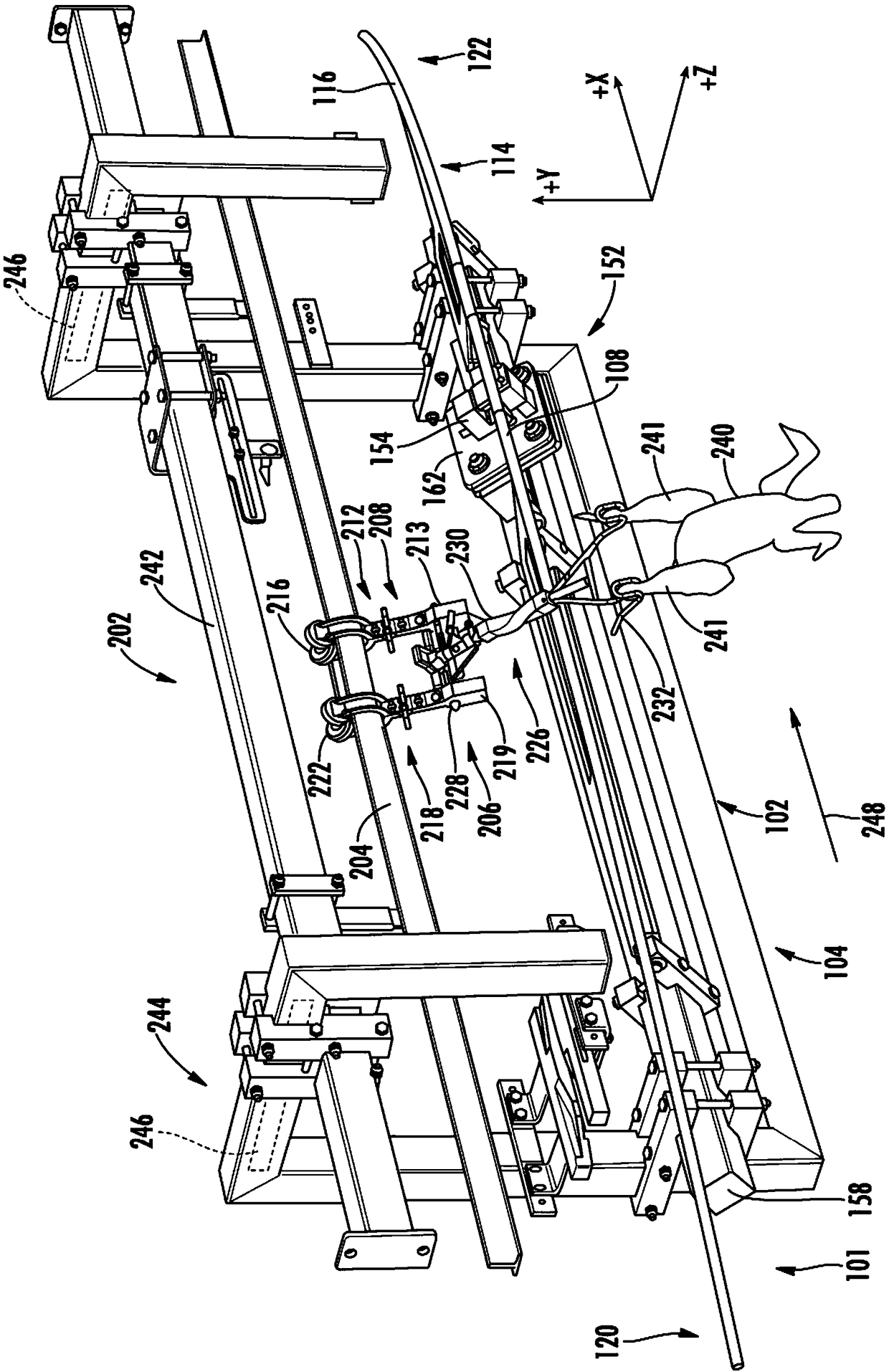

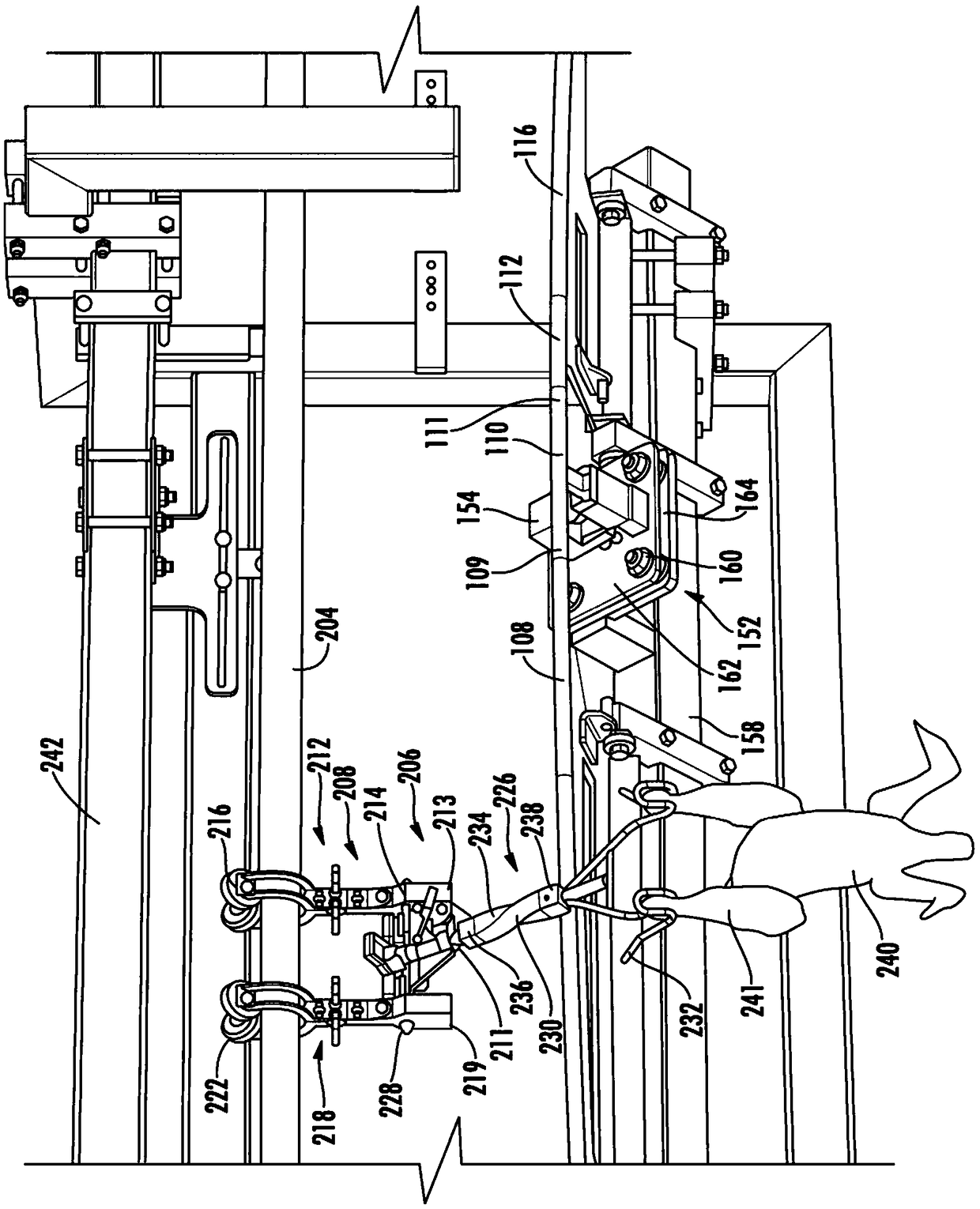

Offset weighing apparatus

ActiveCN109414030AFriction minimizationConveyorsOscillations damping for weighingEngineeringForce sensor

An offset weighing apparatus (152) and method for use with poultry processing equipment includes a weigh assembly to weigh an animal connected to a shackle assembly (206) as the shackle moves in contact with a force sensor (154) along a conveyor line (204). A diverter assembly (102) laterally displaces a shackle retaining the animal from below the conveyor line into engagement with the force sensor. The bending axis of the force sensor is approximately parallel to the displaced shackle. The angular position of the bending axis and shackle, and relative positions, friction, and forces of the components of the shackle assembly and weigh assembly are analyzed to calculate the weight of the animal connected to the shackle without removing the animal from the shackle or ceasing movement of theconveyor line.

Owner:BAADER LINCO INC

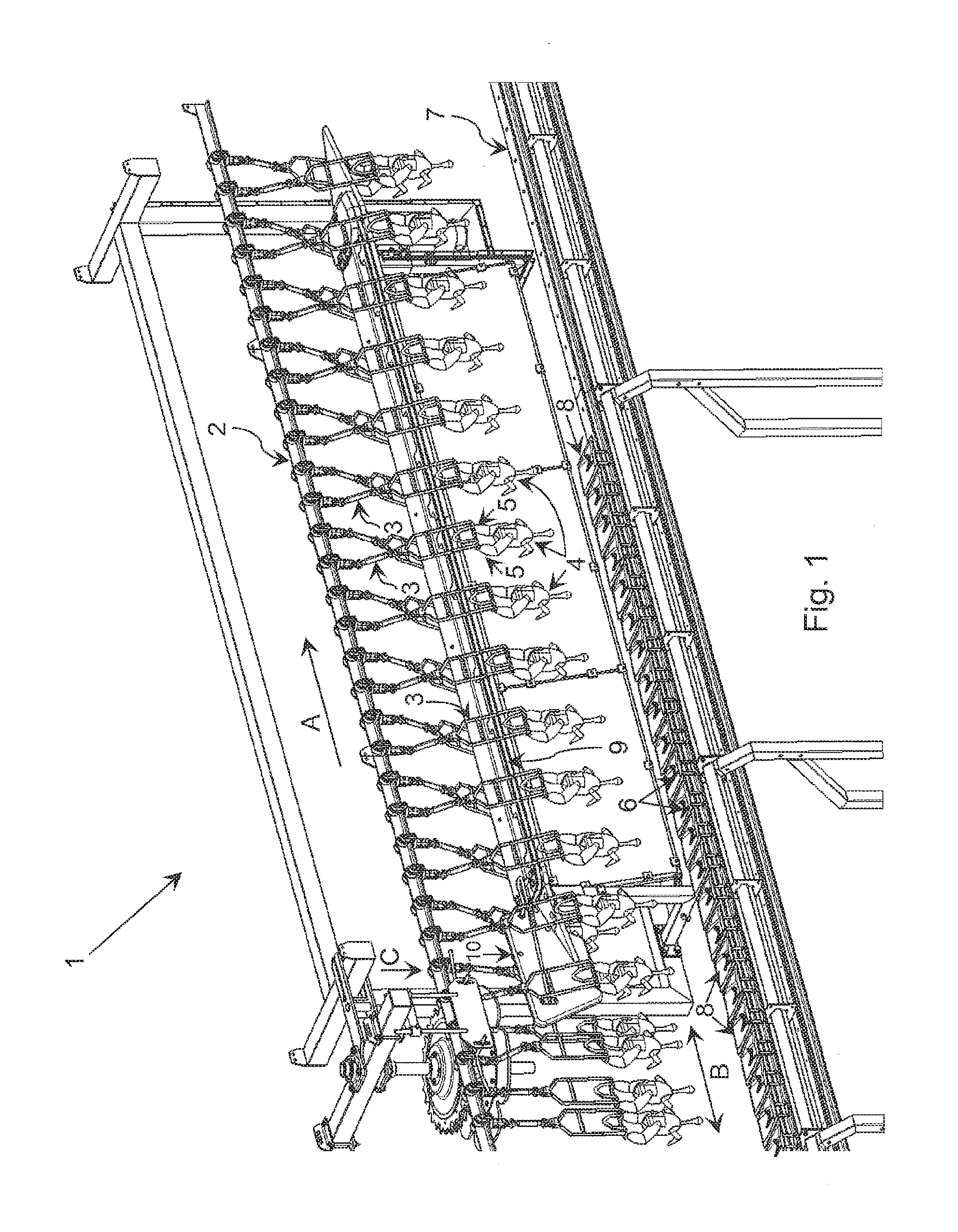

Method and an apparatus for arranging a bird in a position for being suspended from a shackle

ActiveUS10159259B2Reduce error rateLong distancePoultry shacklesPoultry processing support devicesEngineeringShackle

The invention relates to a method and an apparatus for arranging a bird having a body and two legs in a position for being suspended from a shackle. The method comprises the following sequence of steps: I) placing the body of the bird on a support surface with the breast side facing the support surface, II) inserting at least one spreading member between the legs of the bird, so that the breast side of at least one leg comes to rest on a contact surface of the spreading member, and III) forcing the legs away from each other using the spreading mechanism, so that the distance between the hock joints becomes bigger than the distance between the hip joints.

Owner:BAADER FOOD SYST DENMARK AS

Automated poultry hanging system and method

ActiveUS8968060B2Electric current slaughtering/stunningMeat processing plantsControl systemEngineering

This invention relates to automated systems and methods for hanging live poultry for further processing. The system has an alignment conveyor, an alignment stunner, a hanging box, and a shackle. The alignment conveyor conveys poultry from an input point to the alignment stunner. The alignment stunner urges the poultry to move to a desired position on the alignment conveyor and stuns the poultry. The hanging box grasps the stunned poultry and places the poultry into the shackle for further processing. A computer and at least one sensor control operation of the system so that human intervention is minimized.

Owner:HARBEN III GROVER S

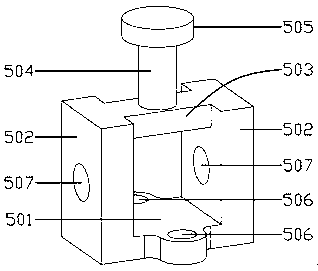

Paw cutter system and method

A paw cutting system for removing a poultry paw from a shackle conveyed along a shackle conveyor line and then cutting the leg of the paw to remove the knuckle is provided. The paw cutter has a guide bar substantially aligned with the shackle conveyor line that urges the paw to a central cavity of the shackle. The paw is discharged from the central cavity into a lateral notch formed in two opposed discs positioned adjacent to an end of the guide bar. The two opposed discs are rotatable and move the paw from the guide bar to a blade. As the paw is moved to the blade, the two discs stretch the paw so that the blade can cleanly cut the paw. The cut paw product can be placed onto a belt or other device in an ordered manner.

Owner:HARBEN III GROVER S

Live duck slaughtering device

ActiveCN109362849AAvoid pollutionReduce breedingElectric current slaughtering/stunningPoultry/fish slaughtering/stunningLife qualityEngineering

The present invention relates to the technical field of live duck slaughtering and particularly discloses a live duck slaughtering device. The live duck slaughtering device comprises a slaughtering box, a conveyor belt, support rods and a disinfecting device; the slaughtering box is internally provided with a fixing platform; an upper end surface of the slaughtering box is internally fixedly connected with the support rods; other ends of the support rods are slidably connected with the conveyor belt; an outer side of the conveyor belt is slidably connected with the fixing platform; a lower endsurface of the conveyor belt is fixedly connected with clamping devices; a front end surface of the fixing platform is fixedly connected with an electric shock device; a front end surface of the slaughtering box is fixedly connected with the disinfecting device; a front right side of the fixing platform is provided with a slaughtering device; and a lower end surface of the slaughtering device isfixedly connected with the disinfecting device. A disinfecting box, a water box and a water pump are arranged; steam generated by high temperature disinfects fixed blades; and the arrangement reducesbreeding of bacteria, ensures life health of people, meets high requirements of modern people for life quality and has very good practical benefits.

Owner:湖南芷江和翔鸭业有限公司

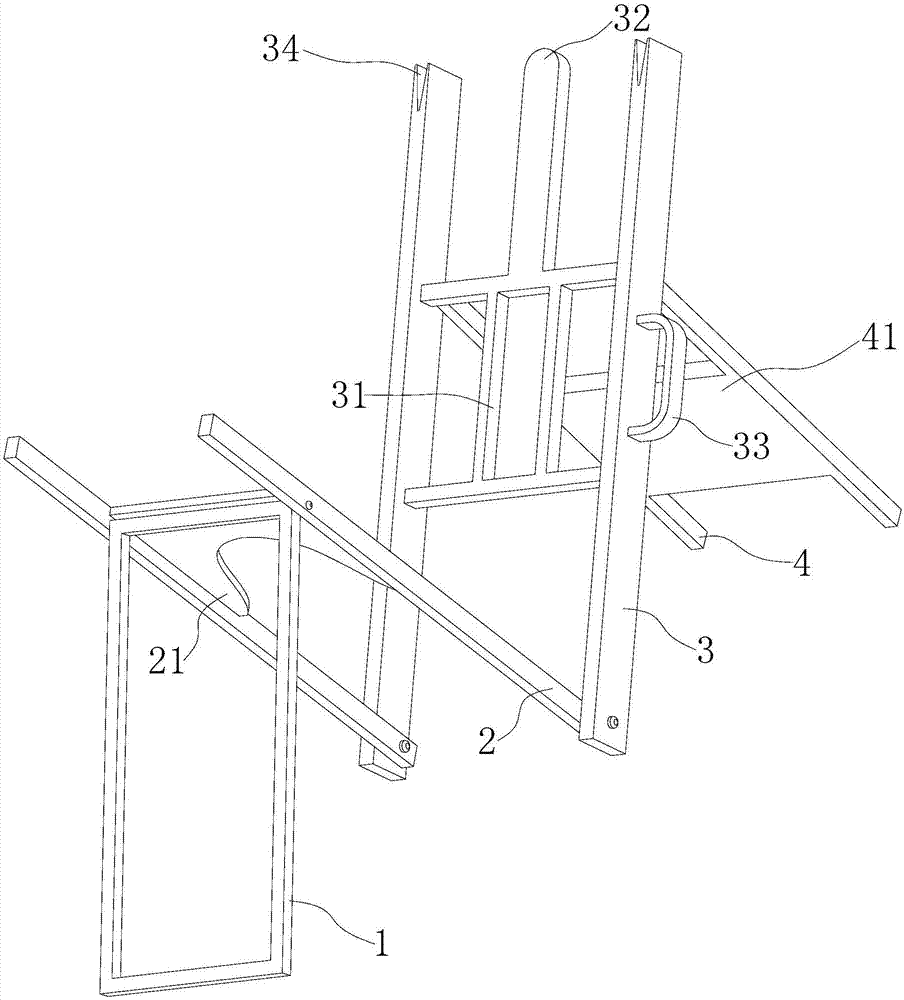

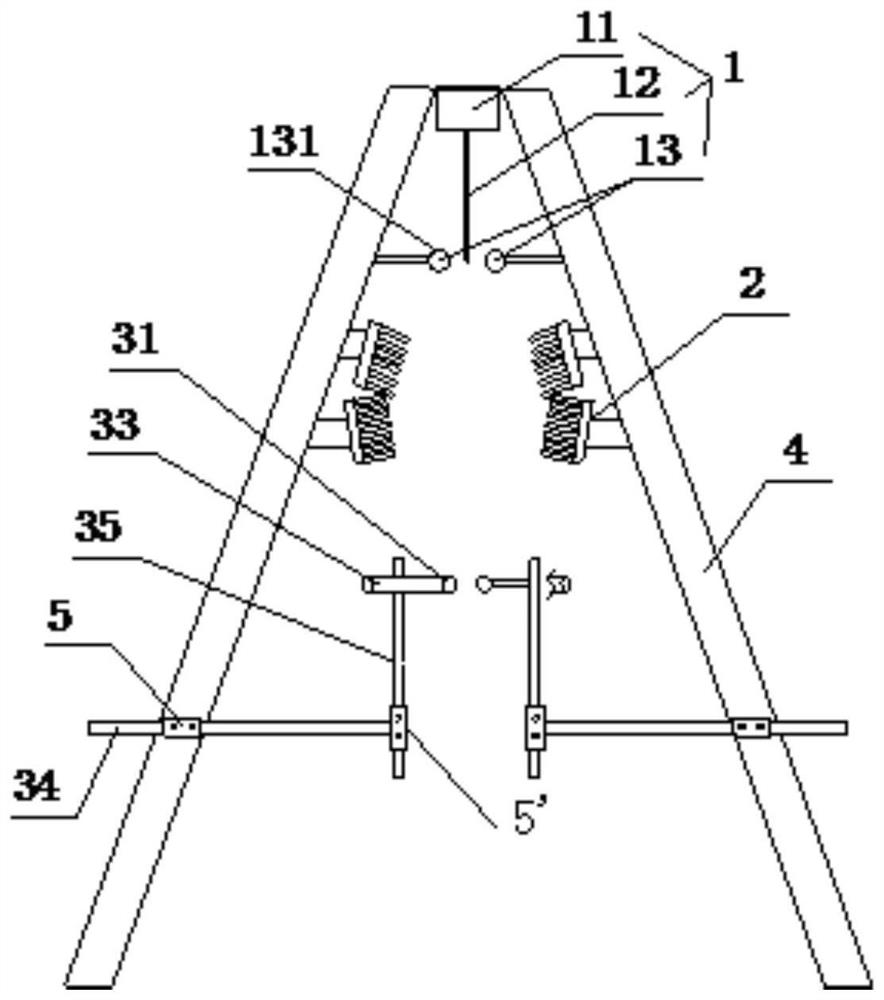

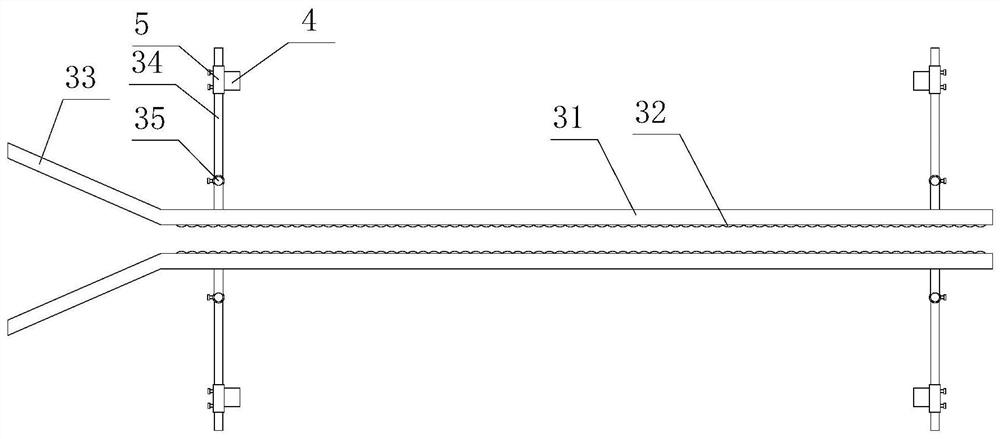

Fixing frame for poultry slaughter

PendingCN107307048AEasy to removeAchieve the purpose of killingPoultry shacklesDividing poultryFixed frameEngineering

Owner:三穗县创惠科技发展有限公司

Paw cutter system and method

A paw cutting system for removing a poultry paw from a shackle conveyed along a shackle conveyor line and then cutting the leg of the paw to remove the knuckle is provided. The paw cutter has a guide bar substantially aligned with the shackle conveyor line that urges the paw to a central cavity of the shackle. The paw is discharged from the central cavity into a lateral notch formed in two opposed discs positioned adjacent to an end of the guide bar. The two opposed discs are rotatable and move the paw from the guide bar to a blade. As the paw is moved to the blade, the two discs stretch the paw so that the blade can cleanly cut the paw. The cut paw product can be placed onto a belt or other device in an ordered manner.

Owner:HARBEN III GROVER S

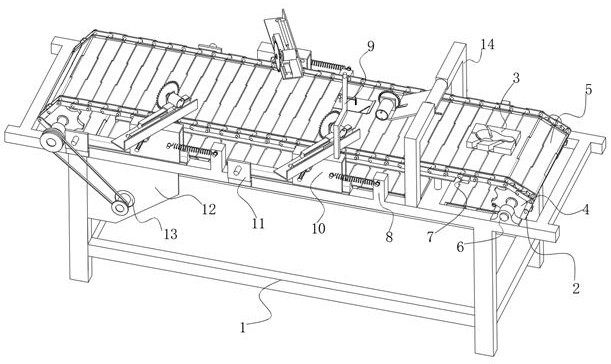

Automatic opening and slitting device for wing and claw trunks of poultry

PendingCN114711276AQuick fixFast shippingPoultry shacklesPoultry transferring/conveying devicesDomestic birdStructural engineering

The invention discloses a poultry wing and claw trunk automatic opening and slitting device which comprises a rack, a transversely-arranged chain plate type conveying mechanism is arranged on the rack, a vertical cutting mechanism for cutting in the length direction of the rack is arranged on the upper portion of the rack, and three inclined cutting mechanisms are arranged on the two sides of the rack in a staggered mode. A power assembly for driving the chain plate type conveying mechanism is arranged on the rack, a slitting fixing die is arranged on the chain plate type conveying mechanism, a containing and placing groove is formed in the slitting fixing die, cutting grooves matched with the vertical cutting mechanism and the three inclined cutting mechanisms are formed in the slitting fixing die, and the cutting grooves are communicated with the containing and placing groove. According to the poultry slitting device, poultry can be stably conveyed, operation is easy, efficiency and convenience are achieved, slitting can be rapidly achieved by combining the vertical cutting mechanism and the inclined cutting mechanism, the production efficiency is improved, meanwhile, the consistency of products is improved, and compared with manual cutting, the cut products are more consistent.

Owner:临沂星阁航天航空科技有限公司

poultry depilator

ActiveCN107751332BAvoid affecting post-processing foodAvoid affecting processingPoultry plucking mechanismsPoultry shacklesAnimal scienceMedicine

Owner:泗县强英食品有限公司

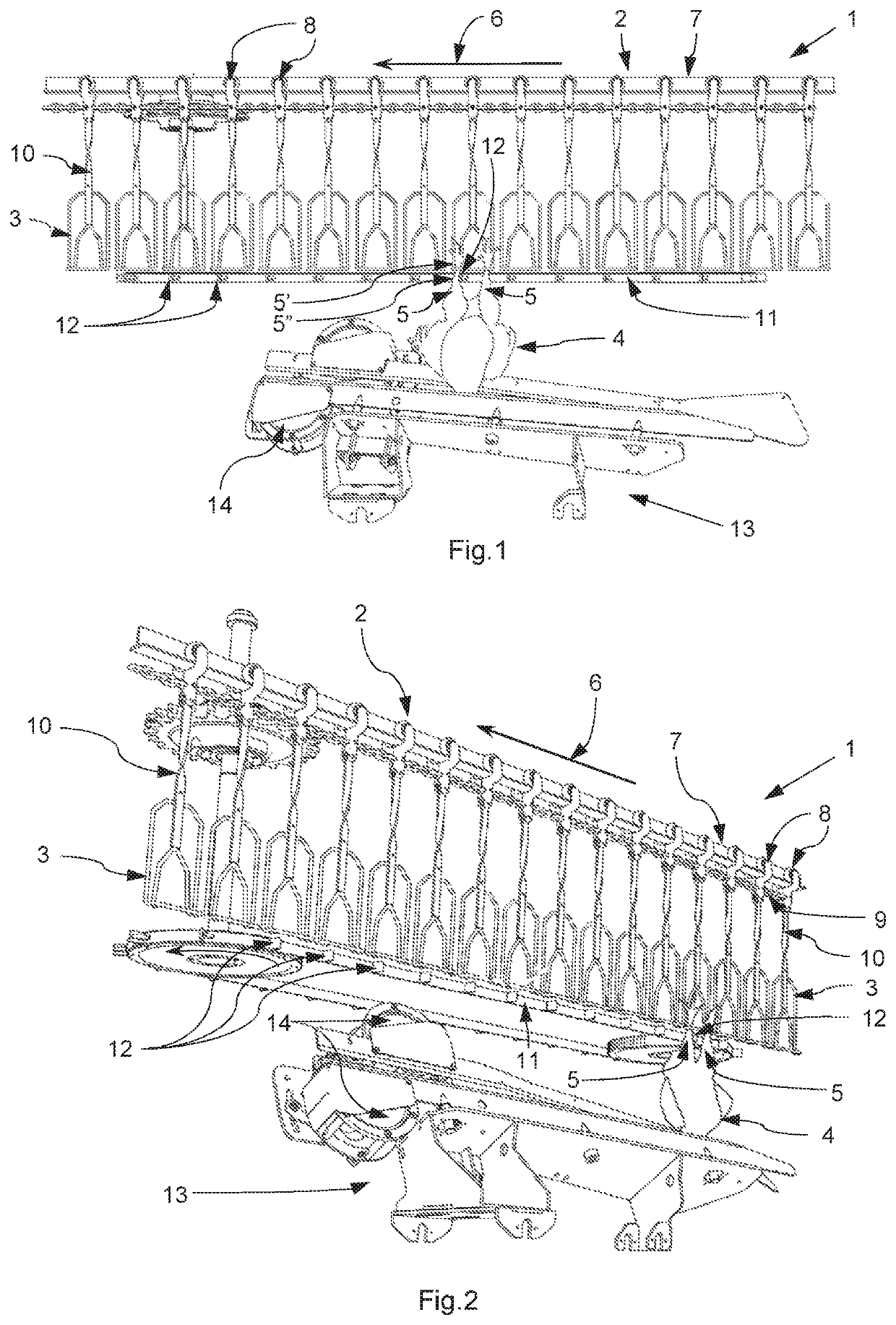

Cutting Unit for Cutting Meat Parts From Suspended Previously Eviscerated Poultry Carcasses

ActiveUS20200138048A1Less cumbersome in assemblyCumbersome operationPoultry shacklesPoultry transferring/conveying devicesAgricultural scienceVertical plane

A Cutting unit and method for cutting meat parts from suspended previously eviscerated poultry carcasses, when the carcasses are each suspended upside-down by their legs from a shackle in an overhead conveyor that transports a succession of shackles through poultry cut-up apparatus. The cutting unit includes at least one cutting element. The cutting unit includes a guiding and positioning member for guiding and positioning a predetermined portion of a poultry carcass in respect of the at least one cutting element. The guiding and positioning member is associated with an auxiliary conveyor adapted to move synchronously with shackles in an overhead conveyor. The auxiliary conveyor has an endless chain articulated about first and second return sprocket. The articulated chain moves in a vertical plane parallel to a vertical plane common to a path of movement of the conveyor shackles.

Owner:FOODMATE

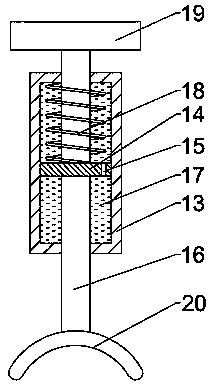

Poultry slaughtering device

PendingCN112841273ARealize automatic throat cutting and bloodlettingImage analysisPoultry shacklesAgricultural engineeringStructural engineering

The invention discloses a poultry slaughtering device, and relates to the technical field of poultry slaughtering processing. The poultry slaughtering device comprises a head fixing structure for clamping the head of a live poultry, a throat limiting structure, a cutting structure, a lifting structure, a cutting depth adjusting structure, an information acquisition assembly and a controller. The head fixing structure comprises two clamping parts and a first moving assembly for driving the two clamping parts to get close to and get away from each other, the throat limiting structure comprises at least three limiting parts which abut against different positions of a throat respectively, and the cutting structure comprises a cutter assembly and a second moving assembly for driving the cutter assembly to move. The three structures are all arranged on the lifting structure so as to synchronously ascend and descend along with the lifting structure, the cutting depth adjusting structure adjusts the position of the cutter assembly or the positions of the limiting parts, the information acquisition assembly is used for collecting head size information of different live poultry, and the controller is in communication connection with all the components. By means of the arrangement, automatic and accurate cutting of different poultry is achieved.

Owner:李建荣

Chicken and duck butchering device

The invention discloses a chicken and duck butchering device. The chicken and duck butchering device comprises a fixed pedestal; a support column is fixedly connected with the left side of the fixed pedestal; an upper crossbeam is fixedly arranged on the right side of the top of the support column; a fixing ring is fixedly connected with the right side of the upper crossbeam; the right side of thefixing ring is connected with a threaded rotating rod through threaded connection; the external side of the threaded rotating rod is fixedly connected with a rotating handle; the internal end of thethreaded rotating rod is rotatingly connected with an external pressing block; the internal side of the external pressing block is fixedly connected with a first spring; the internal side of the firstspring is fixedly connected with an internal pressing block; the internal pressing block and the external pressing block are connected with the fixing ring in a slide manner; the middle part of the support column is fixedly connected with a telescopic rod; the right side of the telescopic is fixedly connected with a fixing plate; the fixing plate is designed to shape like a letter C. Compared with the prior art, the beneficial effects are that: the chicken and duck butchering device can be used for fixing chickens and ducks, butchering can be completed by one operator, in fixing using the chicken and duck butchering device, a problem that blood drain away is not realized because of too high fixing force is avoided, and the chicken and duck butchering device is worthy of popularization.

Owner:济宁鸿润食品股份有限公司

Conveying assembly

Conveying assembly with overhead conveyor having shackles for suspending poultry carcasses by the legs with each shackle suspended from a hanger. A guide element may be disposed generally below and parallel to the overhead conveyor to prevent rotation of the shackles about a vertical axis. The guide element may be movable in the conveying direction and the stops can be mounted on the guide element.

Owner:MEYN FOOD PROCESSING TECH BV

Processing line and method for inspecting poultry carcasses and/or viscera packages

Method and processing line for inspecting a poultry carcass and / or a viscera package taken out from the poultry carcass. The poultry carcass and / or viscera package may be suspended from a poultry carrier and a viscera carrier that move in the processing line. The inspection may be carried out by an inspector selecting a particular poultry carcass and / or viscera package as to be rejected. A selection device can be operated to select the poultry carcass and / or viscera package suspended from the carrier to be rejected.

Owner:MEYN FOOD PROCESSING TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com