A stainless steel passivation process for aviation tubes

A stainless steel and aviation tube technology, applied in the direction of metal material coating process, etc., can solve the problem of poor anti-fingerprint pollution on stainless steel surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

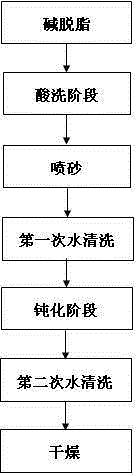

[0025] As one of the best embodiments of a kind of aviation pipe stainless steel passivation process of the present invention, refer to the attached figure 1 , which includes the following steps:

[0026] Alkali degreasing, the stainless steel workpiece is immersed in the alkaline degreasing solution of 59 ℃ for 25 minutes, and the alkaline degreasing solution is an alkaline degreasing solution containing 4.9wt% sodium hydroxide;

[0027] In the pickling stage, soak the stainless steel workpiece with 40°C nitric acid solution for 2 minutes, and then rinse it with tap water at normal temperature;

[0028] Sand blasting, evenly spraying white corundum or glass beads on the surface of the workpiece;

[0029] For the first water washing, soak in tap water at 40°C for 3 minutes, then rinse with tap water at room temperature;

[0030] In the passivation stage, the workpiece is soaked in the mixed solution of nitric acid and sodium dichromate solution at 40°C for 20 minutes to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com