High-performance cooked adhesive powder for wall rendering and preparation method thereof

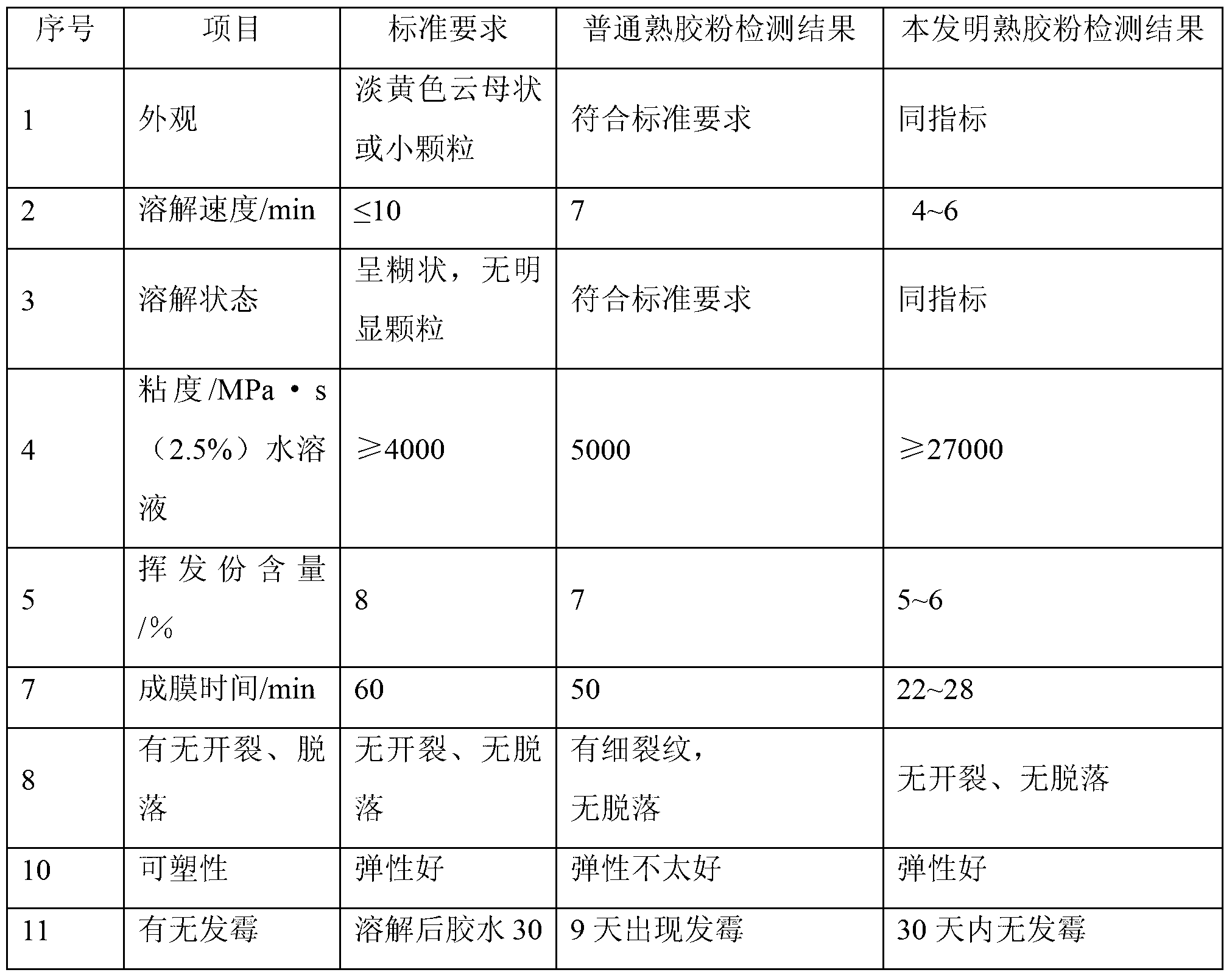

A high-performance technology of cooked rubber powder, applied in the field of cooked rubber powder, can solve the problems of poor anti-mildew and moisture-proof performance, easy shrinkage of putty, peeling and blistering, etc., achieve good crack resistance, improve bonding strength, and good adhesion The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

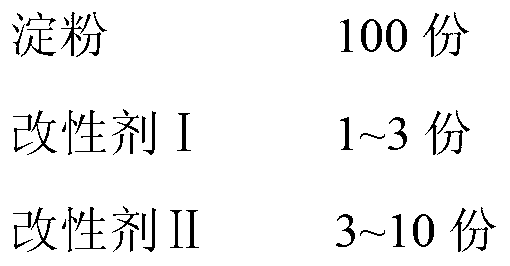

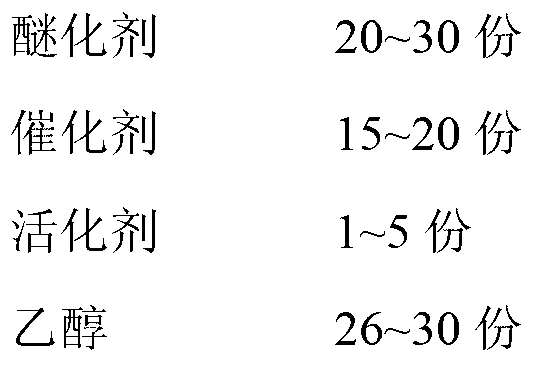

[0032] Prepare wall body plaster according to the following steps and use high-performance cooked rubber powder:

[0033] A. Cross-linking and etherification of starch: add 100 parts by weight of starch into the kneading reactor, and add etherifying agent 20 parts by weight of monochloroacetic acid, 1 part by weight of epichlorohydrin and 26 parts by weight of ethanol under stirring. , stirring for 60-70 minutes, and controlling the temperature at 50-60°C to obtain cross-linked and etherified starch;

[0034] B. Grafting, gelatinization, etherification, and activation of starch: Add 15 parts by weight of catalyst sodium hydroxide dropwise to the crosslinked and etherified starch obtained in step A, control the temperature at 50-70°C, and react for 30-40 Minutes later, sequentially add 3 parts by weight of modifier II and 1 part by weight of activator, and continue the reaction for 30 to 40 minutes to obtain grafted, gelatinized, etherified and activated starch;

[0035] C. Hy...

Embodiment 2

[0039] Prepare wall body plaster according to the following steps and use high-performance cooked rubber powder:

[0040] A. Cross-linking and etherification of starch: add 100 parts by weight of starch into the kneading reactor, add etherifying agent 26 parts by weight of monochloroacetic acid, 2 parts by weight of modifier I and 28 parts by weight of ethanol under stirring. Stir for 70-80 minutes, control

[0041] The processing temperature is 50-60°C to obtain cross-linked and etherified starch;

[0042] B. Grafting, gelatinization, etherification, and activation of starch: Add 17 parts by weight of catalyst sodium hydroxide dropwise to the crosslinked and etherified starch obtained in step A, control the temperature at 50-70°C, and react for 40-50 minutes. Minutes later, sequentially add 6 parts by weight of modifier II and 4 parts by weight of activator, and continue to react for 40 to 50 minutes to obtain grafted, gelatinized, etherified and activated starch;

[0043] ...

Embodiment 3

[0047]Prepare wall body plaster according to the following steps and use high-performance cooked rubber powder:

[0048] A. Cross-linking and etherification of starch: Add 100 parts by weight of starch into the kneading reactor, add etherifying agent 30 parts by weight of monochloroacetic acid, 3 parts by weight of modifier I and 30 parts by weight of ethanol under stirring. Stir for 80-90 minutes, and control the temperature at 50-60°C to obtain cross-linked and etherified starch;

[0049] B. Grafting, gelatinization, etherification and activation of starch: Add 20 parts by weight of catalyst sodium hydroxide dropwise to the cross-linked and etherified starch obtained in step A, and control the temperature at 50-70°C for 40-50 minutes. Minutes later, sequentially add 10 parts by weight of modifier II and 5 parts by weight of activator, and continue the reaction for 50 to 60 minutes to obtain grafted, gelatinized, etherified and activated starch;

[0050] C. Hydrolysis reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com